Anti-fog lens with dopamine as surface bonding layer, and technological process thereof

A technology of surface bonding and dopamine, which is applied in the application field of anti-fog glasses lens production, can solve the problems of inability to realize anti-fog function and inability to add anti-fog function to glasses, and achieve the effect of strong practicability, novelty and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

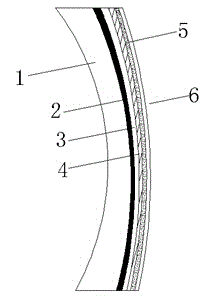

[0020] From figure 1 Known, the present invention adopts dopamine as the anti-fog lens made of resin lens surface bonding layer, successively by resin substrate 1, adds dura mater layer 2, anti-reflection film layer 3, waterproof film layer 4, dopamine bonding layer 5, The anti-fog film layer 6 is composed of a dopamine adhesive layer 5 dipped on the surface of the waterproof film layer 4 , and a hydrophilic anti-fog film layer 6 is dip-coated and bonded on the surface of the dopamine adhesive layer 5 . The resin lens substrate 1 is a resin lens with a refractive index of 1.499, 1.56, 1.60, 1.67, 1.71, 1.74, 1.76, and the substrate monomer material is allyl diglycol carbonate, dipropylene isophthalate , a kind of amino resin. The hard coating layer 2 adopts silicon dioxide hardening liquid or TS-56-T resin lens hardening liquid. The anti-reflection film 3 is an anti-reflection film layer evaporated under vacuum conditions using zirconia and magnesium oxide materials using a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com