Holder positive and negative side discrimination device

A technology for distinguishing devices and cages, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of missed detection and low discrimination efficiency, and achieve the effect of simple discrimination process, high discrimination efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

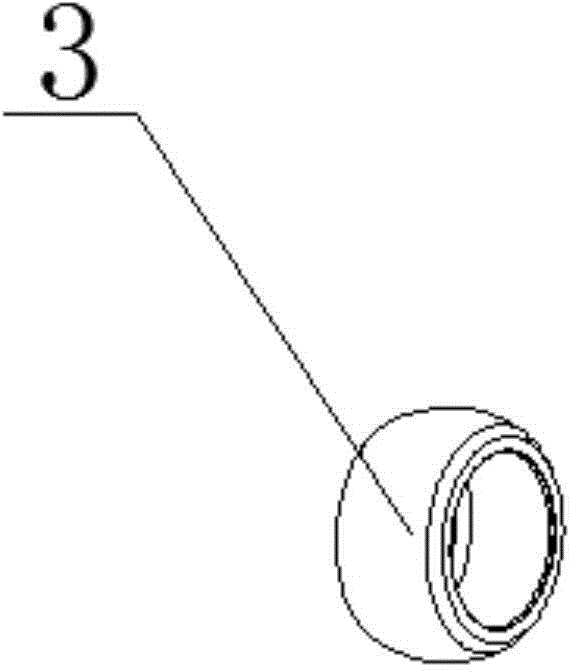

[0026] See attached figure 1 As shown, the cage 3 mentioned in the present invention refers to a metal structure formed after turning, the inner and outer surfaces of which are spherical, and the two ends are planes.

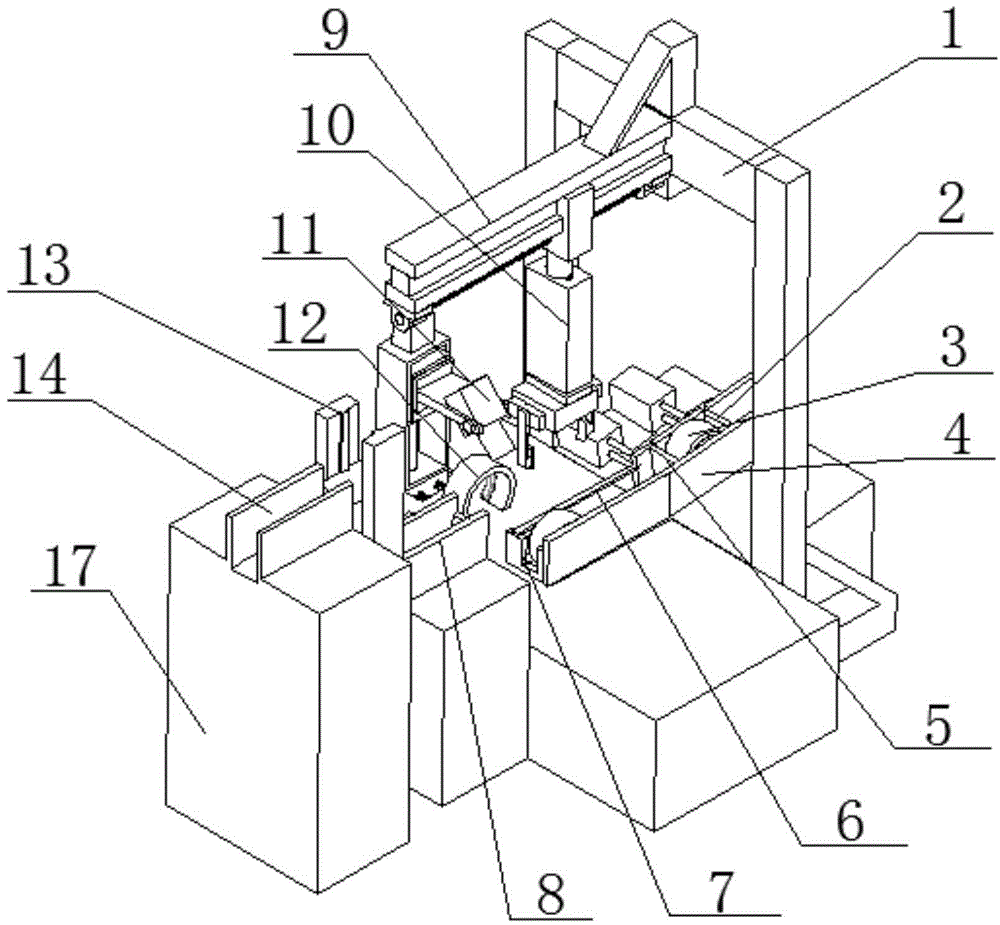

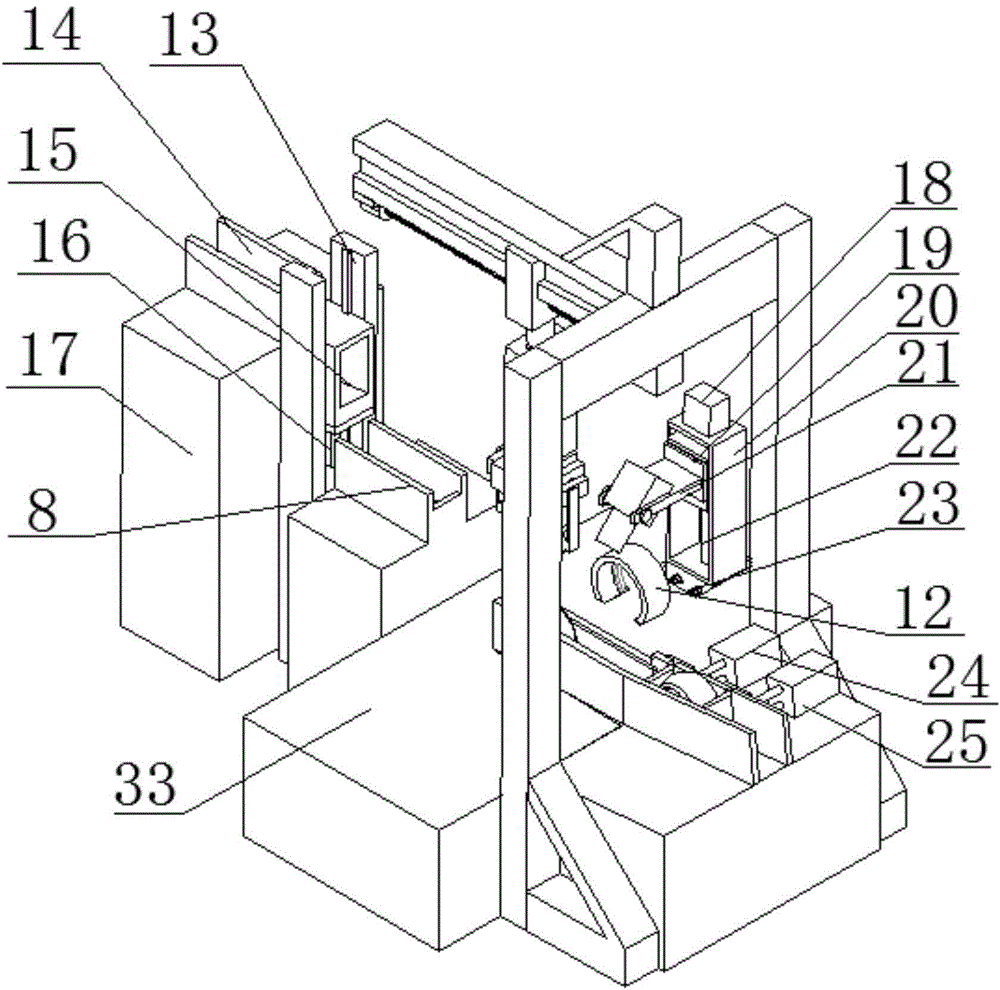

[0027] Such as figure 2 , 3 , 4, the positive and negative discrimination device of the cage of the present invention includes a frame 33, on which a guide mechanism for the cage 3 entering, a cage discrimination mechanism, a cage moving mechanism, and a retaining frame 33 are arranged. Frame lifting mechanism and main control machine.

[0028] The cage guiding mechanism, the cage discriminating mechanism, the cage moving mechanism and the cage lifting mechanism are all installed on the frame 33, the cage guiding mechanism is vertically connected with the cage discriminating mechanism, and the cage moving mechanism is positioned at the cage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com