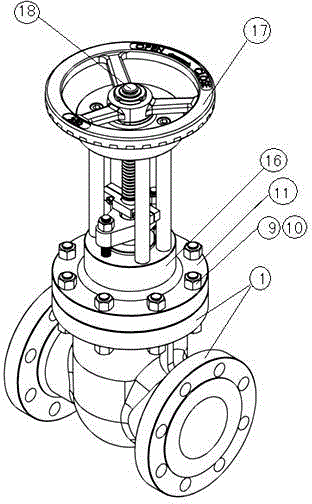

Parallel type double-gate gate valve

A double gate, parallel technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of troublesome maintenance and disassembly, many sealing parts, high processing precision, etc., and achieve material saving, good sealing performance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

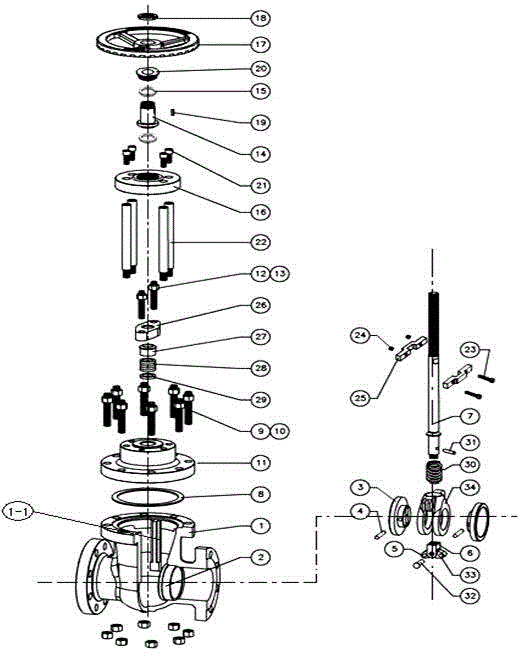

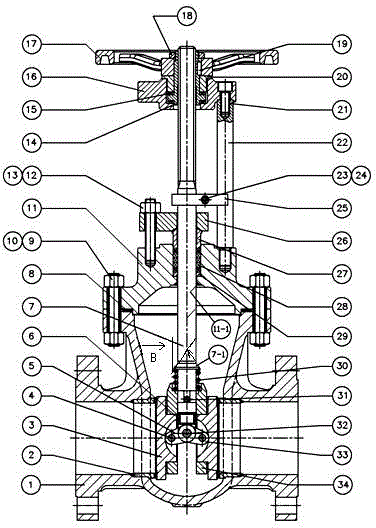

[0015] Embodiment, with reference to the accompanying drawings, a parallel double gate valve includes a handwheel 17 fixed with a round nut 18 on the upper end of the stem nut 14, and a flat key 19 is fixedly connected between the stem nut 14 and the handwheel 17 , the strut flange 16 is fixed on the valve cover 11 with four columns 22, the packing pressure sleeve 27 is equipped with a packing pressure plate 26, the packing pressure plate 26 is fixedly connected with the valve cover 11 with the pressure plate stud 12 and the pressure plate nut 13, the valve cover A gasket 8 is installed between 11 and the valve body 1, which are connected by bolts. Valve stem 7 upper ends are threadedly connected with valve stem nut 14, and the upper and lower shoulders of valve stem nut 14 are equipped with thrust bearing 15, and bearing gland 20 is housed above thrust bearing 15. Both the packing 28 and the packing pad 29 are installed in the stuffing box provided on the valve cover 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com