Twin-screw compressor with intermediate air-pumping function and multiple-temperature-zone heat pump system

A compression system, twin-screw technology, applied in the direction of compression machines with multiple condensers, compressors, components of pumping devices for elastic fluids, etc., can solve the problem of large irreversible losses, low efficiency and reliable systems Reduced performance and other issues, to achieve the effect of reducing initial investment costs, improving system efficiency, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings:

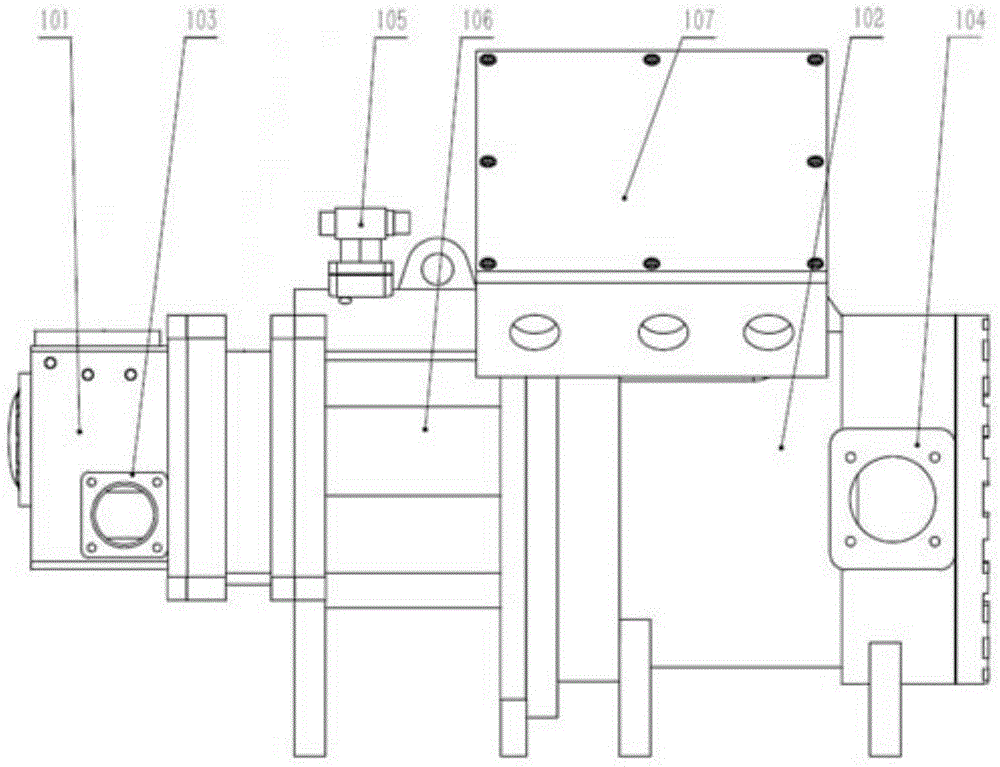

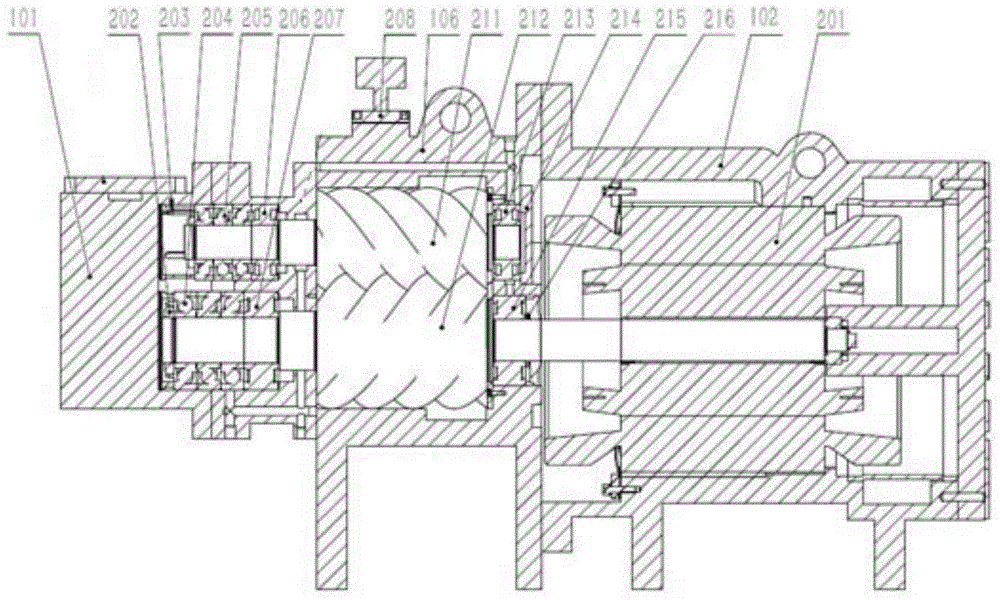

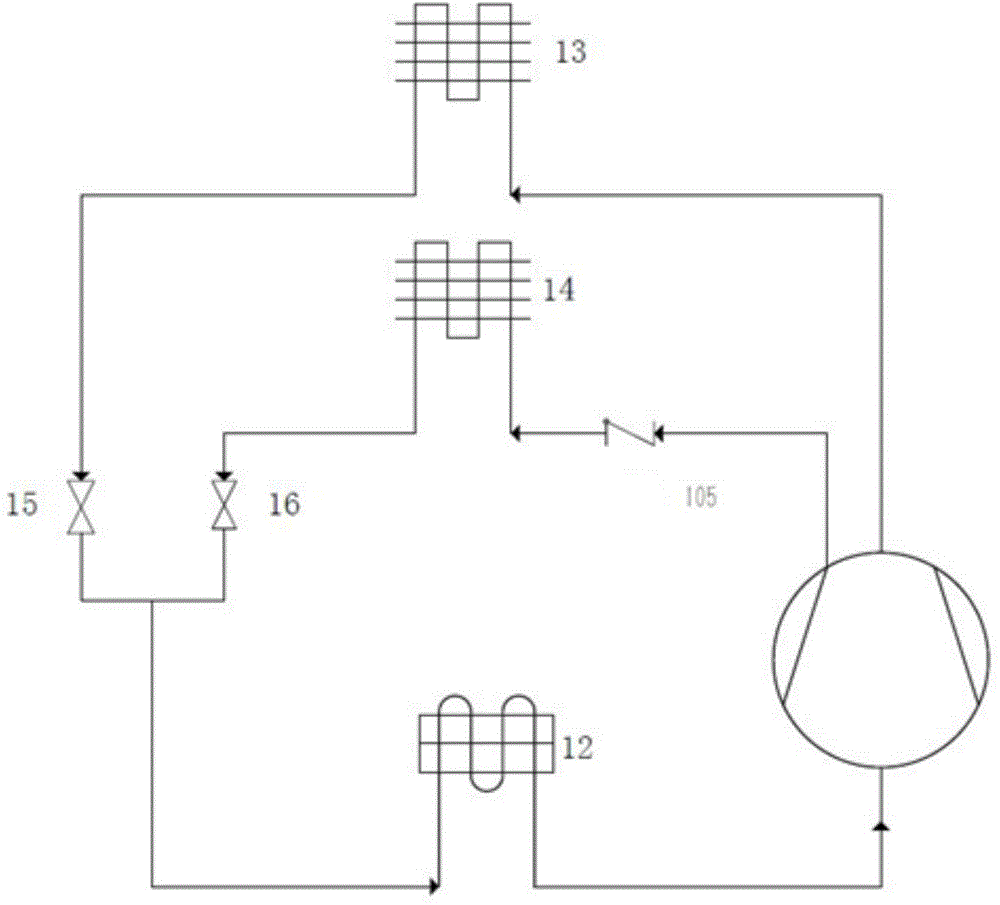

[0028] reference figure 1 and figure 2 The twin-screw compressor with intermediate air extraction function of the present invention includes a motor system, a compression system and an exhaust end seat 101; the compression system includes a male rotor 212, a female rotor 211 and a body 106, a male rotor 212 and a female The rotors 211 are all provided in the body 106, the side of the male rotor 212 is meshed with the side of the female rotor 211, the side of the body 106 is provided with an exhaust port 208, and the exhaust port 208 is provided with an exhaust control valve 105, The air orifice 208 is opened in the middle compression section of the machine body 106 along the spiral direction; the motor system includes a motor housing 102, a variable frequency motor 201, and a junction box 107 arranged on the outside of the motor housing 102. Fixed in the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com