Construction method of lane filling retained roadway

A construction method and a technology of roadway retention, applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of wasting coal resources, increasing the amount of roadway excavation, etc., and achieves wide application, low construction cost, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

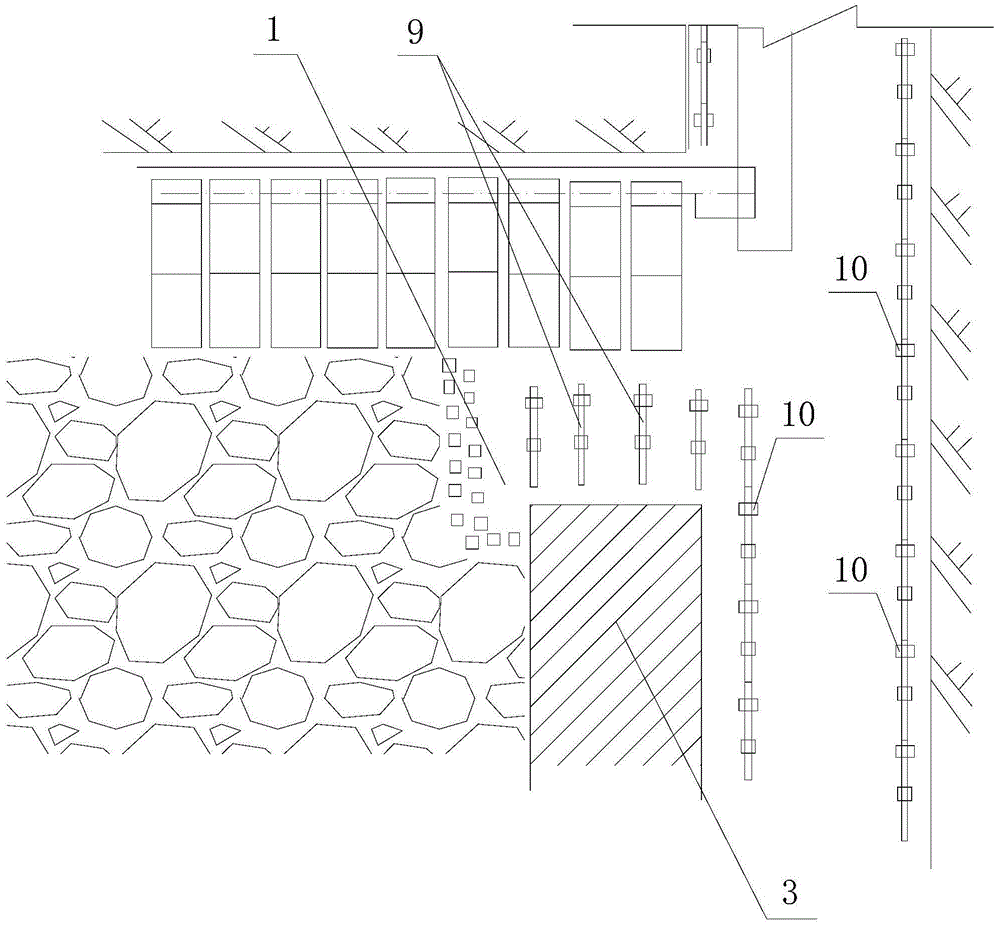

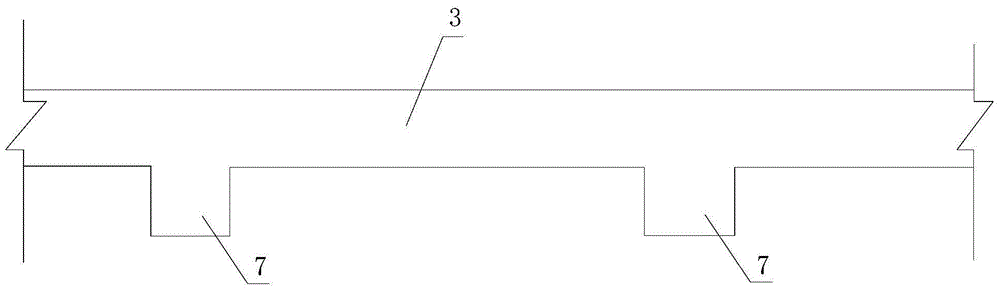

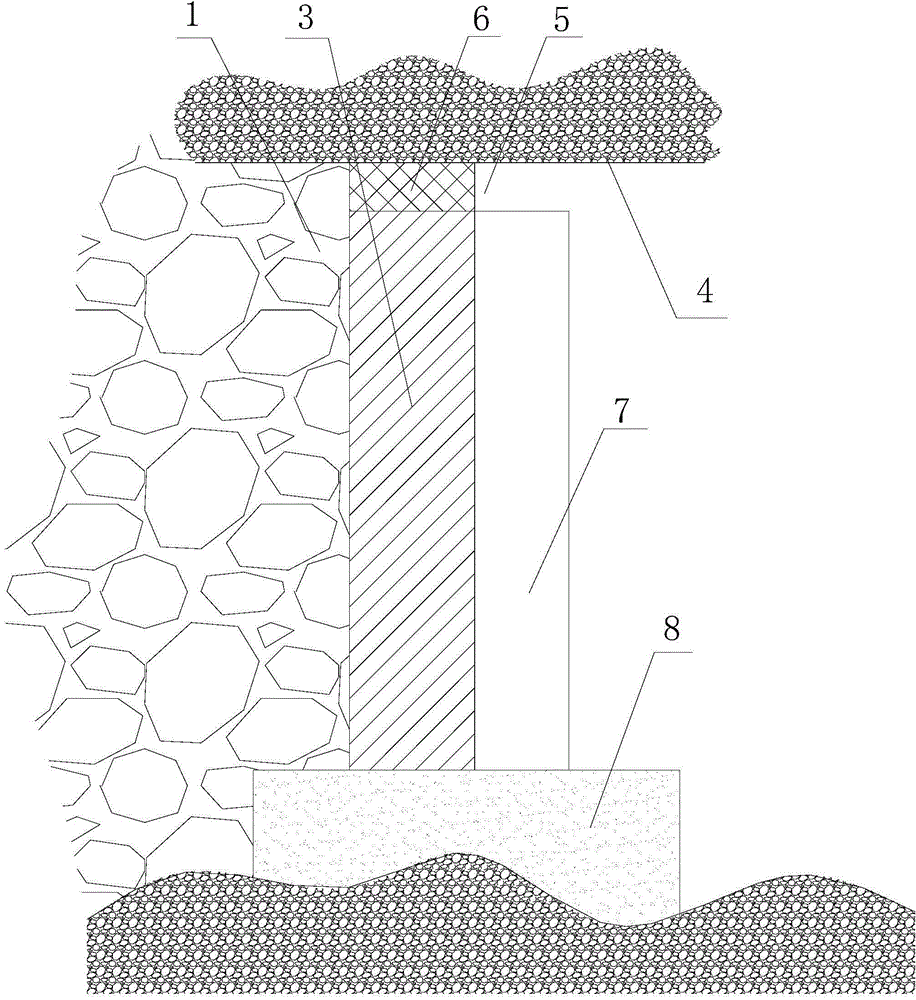

[0026] Such as figure 1 , figure 2 as well as image 3 Shown is a construction method provided by the present invention that can transform the transport lane of the previous working face quickly, simply, and with low construction costs and retain the side of the return air lane to become the return air lane of the next working face. The construction method includes the following steps,

[0027] a. The filling material is made by using the waste gangue discharged from the mine, and then adding cement and fly ash after crushing to make regular concrete blocks as the filling material;

[0028] b. Foundation treatment: According to the coal mining progress and the mining step distance, the bottom of the roadway under the working face lagging behind by 1-2m is cleaned to the hard bottom, and cement mortar is pre-spread on the cleaned bottom to complete the foundation treatment;

[0029] c Filling body construction, according to the coal mining progress and mining step distance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com