Intermittent shaft bottom pressure difference reduction sub

A bottom-hole differential pressure, intermittent technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of harsh application conditions, high process requirements, and no popularization and application, and achieves the improvement of jet depressurization effect. Application prospect, effective and feasible effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

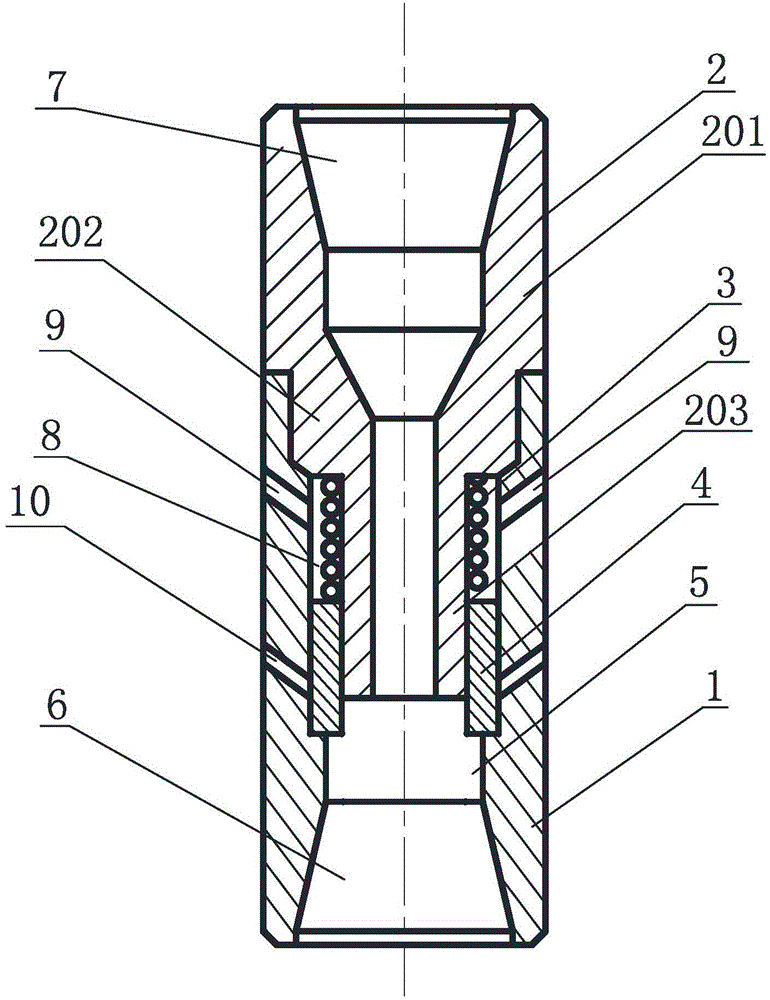

[0023] With reference to the accompanying drawings, an intermittent bottomhole pressure drop nipple includes an outer cylinder 1 , a drill pipe joint 2 , a spring 3 and an annular piston 4 . The outer cylinder 1 is provided with a through shaft hole 5 along its axial direction, the lower end of the outer cylinder 1 is provided with a water outlet 6 and a screw thread for connecting a drill bit, and the upper end of the outer cylinder 1 is connected with a drill pipe joint 2 . The drill pipe joint 2 is mainly composed of three cylinders with different diameters, namely the upper cylinder 201 of the drill pipe joint, the middle cylinder 202 of the drill pipe joint and the lower cylinder 203 of the drill pipe joint. The axial direction is sequentially connected and fixed downwards. The drill pipe joint 2 is partially inserted into the shaft hole. The outer wall of the cylinder in the middle of the drill pipe joint and the circumference of the inner wall of the outer cylinder are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com