Shell powder sea surface spreader

A technology of shell powder and nozzle frame, which is applied in the cleaning of open water, water conservancy projects, and general water supply conservation, etc. It can solve the problem that the direction of the nozzle cannot be changed conveniently, and achieves good fixing effect and small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

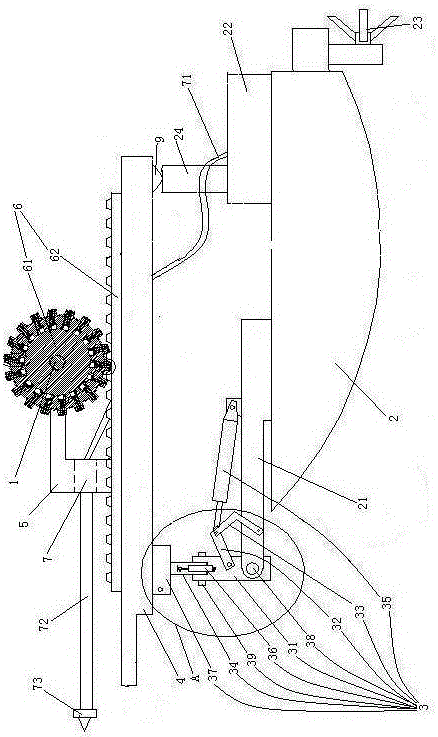

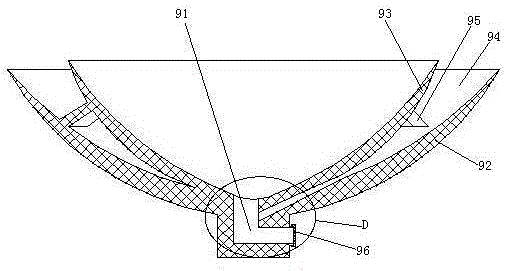

[0027] seefigure 1 , a shell powder sea surface spreader, including a hull 2, a reversing joint 3, a nozzle frame 4, a carriage 5, a translation mechanism 6 and a spray pump 7.

[0028] The hull 2 is provided with an installation seat 21, a shell powder storage box 22, a water propulsion mechanism 23 and a support seat 24. The propulsion mechanism 23 on water is a propeller.

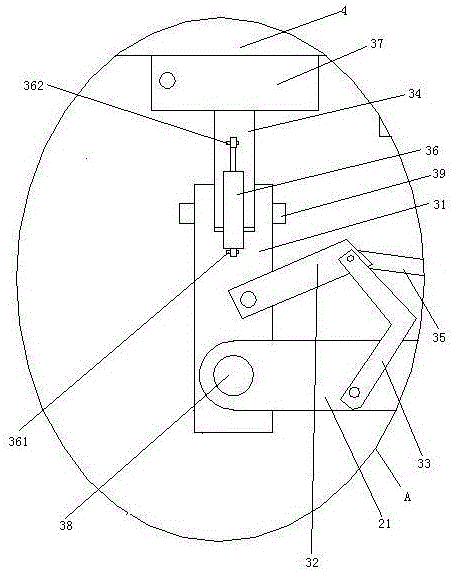

[0029] Reversing joint 3 packs base 31, first connecting rod 32, second connecting rod 33, connection seat 34, base swing oil cylinder 35, connection seat swing oil cylinder 36 and swivel seat 37. One end of the base 31 is hinged with the mounting base 21 through the base hinge shaft 38 . One end of the first connecting rod 32 is hinged together with the base 31 , and the other end is hinged together with one end of the second connecting rod 33 and the piston rod of the base s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com