Foam scrubbing agent used for water drainage and gas collection of water-production gas well containing H2S gas

A technology for drainage and gas extraction and foam removal, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems such as the performance of foam removal agent decreasing, restricting the application of foam drainage and gas extraction, and achieves high foaming properties. , has the effect of environmental friendliness and low irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example provides a method for containing H 2 Foaming agent for water drainage and gas recovery of S gas production wells.

[0025] In terms of mass percentage, the raw material composition of the foaming agent includes: 20% sodium fatty alcohol polyoxyethylene ether sulfate, 30% cocamidopropyl betaine, 10% sodium α-olefin sulfonate and 40% deionized water .

[0026] The preparation method of this foam discharge agent comprises the following steps:

[0027] a. Slowly add fatty alcohol polyoxyethylene ether sodium sulfate and cocamidopropyl betaine into a stainless steel reaction kettle, then add solvent (deionized water) to obtain a mixed solution, heat the mixed solution to 45°C, and stir at a low speed 15min;

[0028] b. Slowly add sodium α-olefin sulfonate to the above mixed solution, and continue to stir at a low speed for 10 minutes to obtain the foam discharge agent WJ-1.

Embodiment 2

[0030] This example provides a method for containing H 2 Foaming agent for water drainage and gas recovery of S gas production wells.

[0031] In terms of mass percentage, the raw material composition of the foaming agent includes: 28% sodium fatty alcohol polyoxyethylene ether sulfate, 35% cocamidopropyl betaine, 14% sodium α-olefin sulfonate and 23% deionized water .

[0032] The preparation method of this foam discharge agent comprises the following steps:

[0033] a. Slowly add fatty alcohol polyoxyethylene ether sodium sulfate and cocamidopropyl betaine into a stainless steel reaction kettle, then add solvent (deionized water) to obtain a mixed solution, heat the mixed solution to 45°C, and stir at a low speed 15min;

[0034] b. Slowly add sodium α-alkenyl sulfonate to the above mixed solution, and continue to stir at a low speed for 10 minutes to obtain foam discharge agent WJ-2.

Embodiment 3

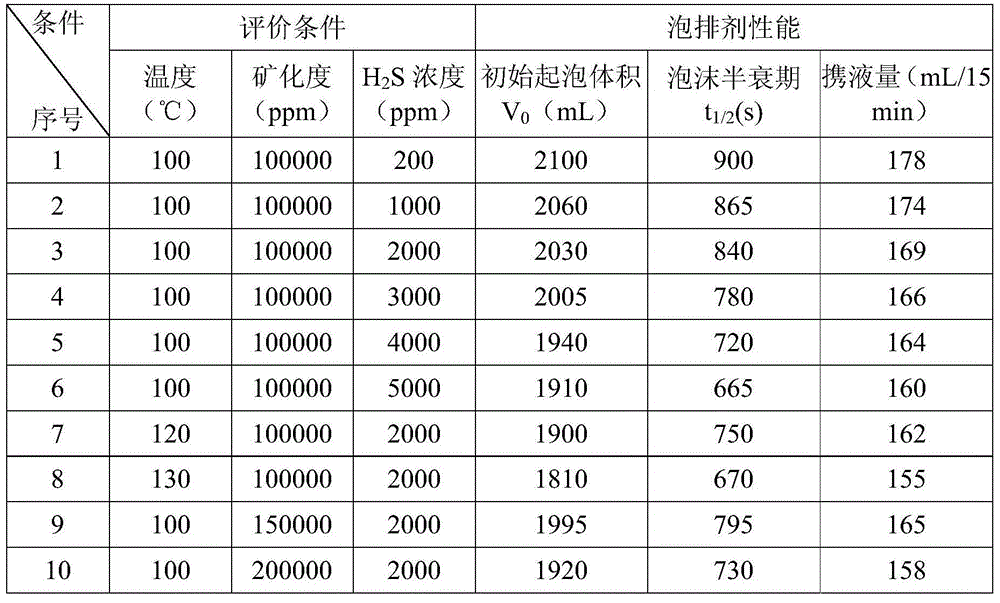

[0036] In this embodiment, the foam discharge agent WJ-1 provided in the above-mentioned embodiment 1 is treated at different H 2 The initial foaming volume V under the conditions of S concentration, temperature and salinity 0 , foam half-life t 1 / 2 And the liquid carrying capacity of 15min when the gas flow is 5L / min was tested.

[0037] The instrument used in the test of this embodiment is a high-temperature and high-pressure foam evaluation instrument (this high-temperature and high-pressure foam evaluation instrument is the high-temperature and high-pressure foam evaluation instrument recorded in the utility model patent of Patent No. ZL201120400940.1, and the announcement number is CN202228059U); After analysis based on water produced from natural gas wells on site, NaCl, CaCl 2 , MgCl 2 , KCl, Na 2 SO 4 , NaHCO 3 Prepared; the foaming agent solution used in the test was obtained by dissolving the foaming agent provided in Example 1 in simulated formation water; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com