Mine timber substitute material and preparation method thereof

A technology of pit wood and magnesium chloride hexahydrate, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of eating forest resources, large economic burden, environmental protection, etc., and achieves a simple and easy preparation method line, short production cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

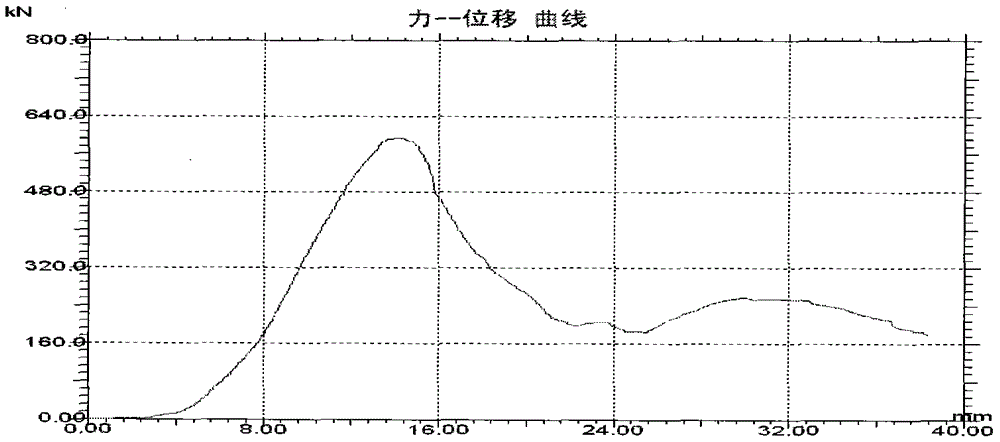

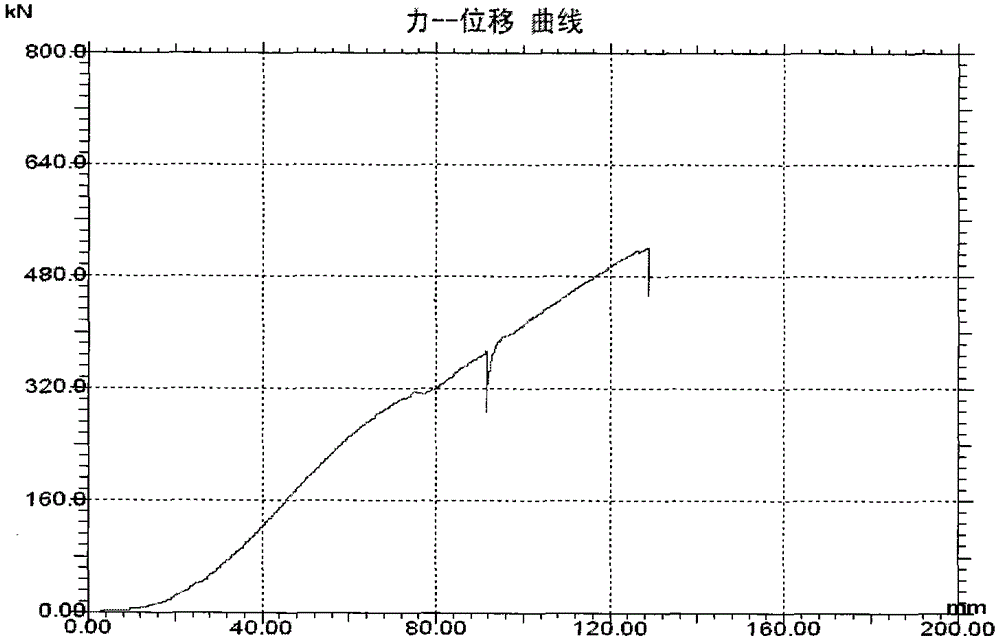

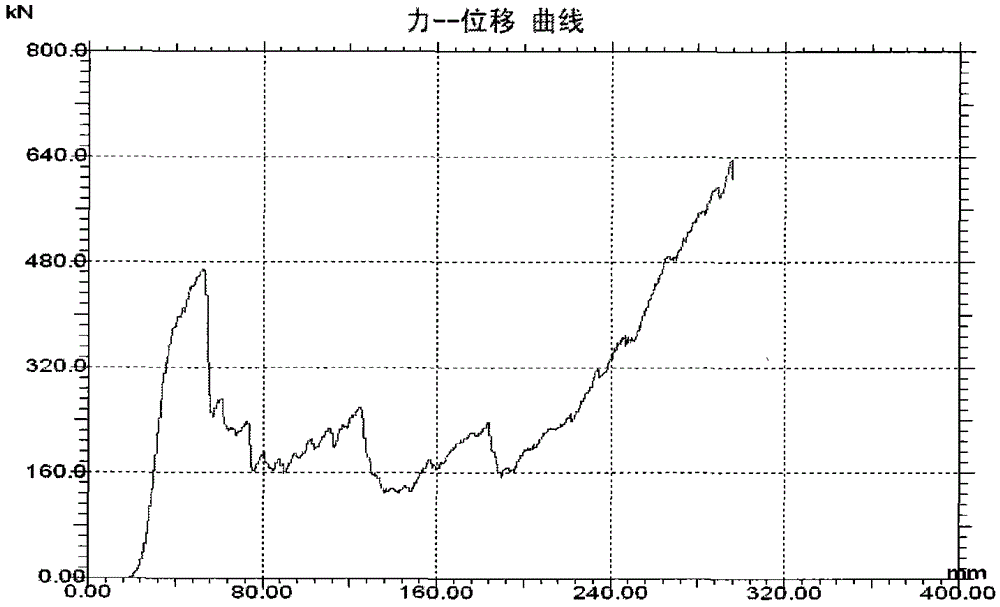

[0018] refer to figure 1 , the specific embodiment adopts the following technical scheme: the pit wood substitute material of the present invention is mainly composed of three components: main material, fiber and composite admixture, wherein the main material includes 100 parts of magnesium oxide powder, 70-90 parts of magnesium chloride hexahydrate solution 10-15 parts of fly ash, 12-15 parts of sawdust, 5-8 parts of water; the composite admixture includes 1-4 parts of water reducer, 0.2-0.4 parts of retarder and 2-4 parts of modifier; The fiber comprises glass fiber and green bamboo, wherein 2-4 parts of glass fiber and 25-45 parts of green bamboo.

[0019] Described magnesium chloride hexahydrate solution is prepared by magnesium chloride hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com