A countercurrent sludge drying device

A sludge drying and countercurrent technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of limited sludge water reduction, failure to meet combustion requirements, high cost, etc., and achieve reasonable energy utilization and dry The effect of continuous chemicalization process and sufficient exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

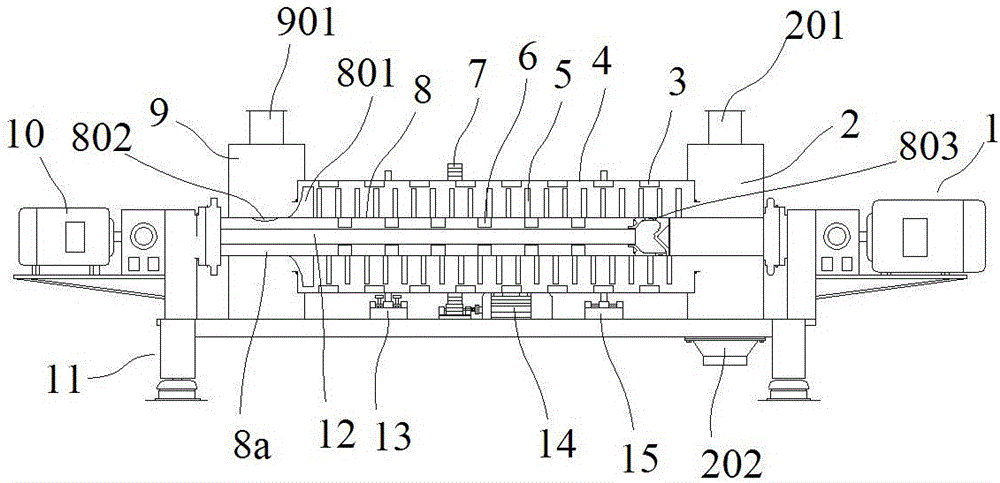

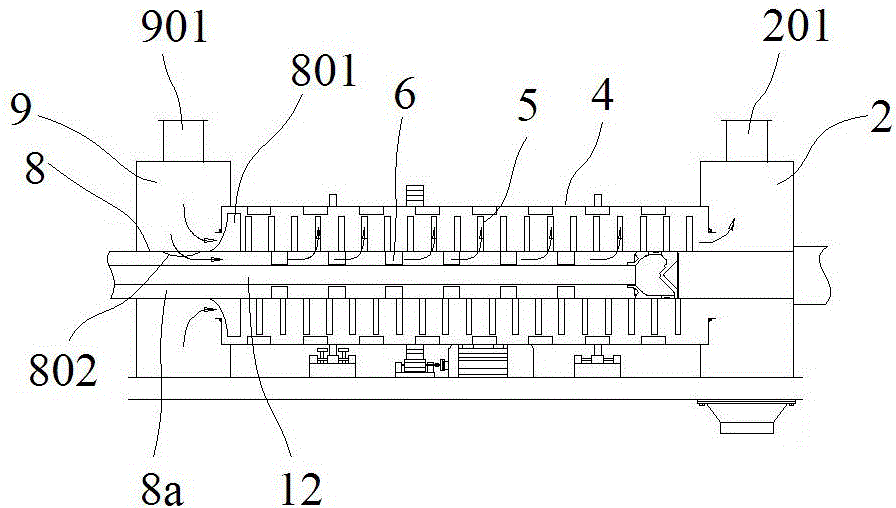

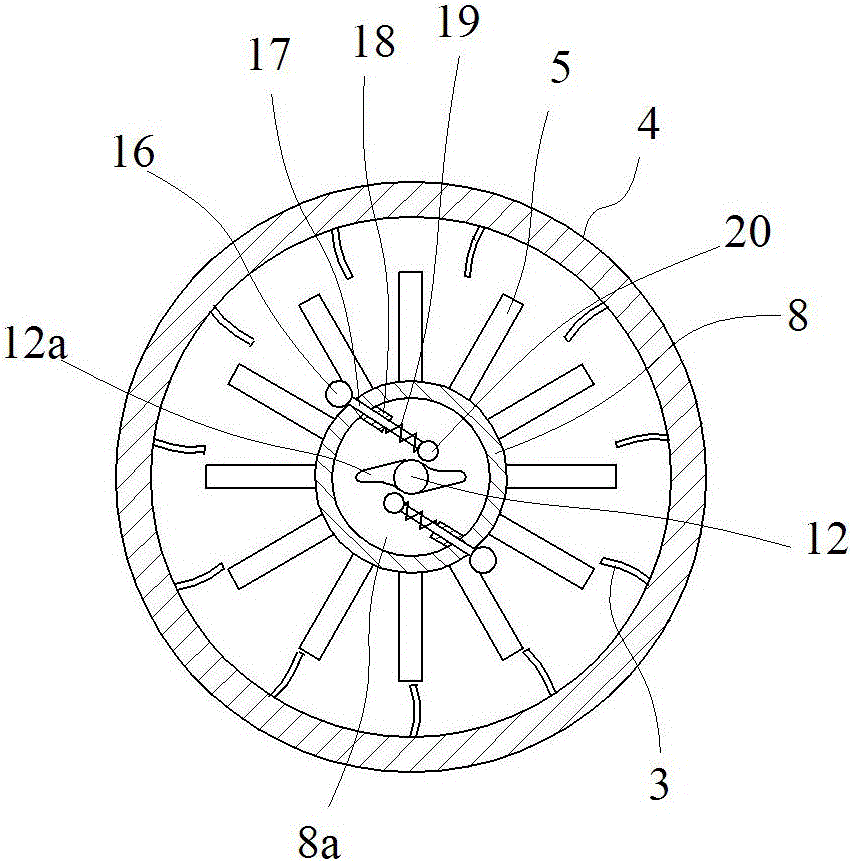

[0021] Such as figure 1 In the shown embodiment, a countercurrent sludge drying device includes a drying outer cylinder 4 , a rotor 8 , a feed pipe 12 and a frame 11 . The drying outer cylinder is horizontally arranged on the rack, and one end of the drying outer cylinder is provided with an air inlet chamber 9, and the other end is provided with a settling chamber 2, and the air inlet chamber and the settling chamber play a supporting role for the drying outer cylinder, while drying The outer cylinder can rotate relative to the air inlet chamber and the settling chamber. The frame is provided with a retaining wheel 13 at one end of the drying outer cylinder, and a support roller 15 at the other end, which supports and positions the drying outer cylinder and ensures that the drying outer cylinder can rotate smoothly. The outer wall of the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com