Eccentric turning wheel device

An indexing wheel and eccentric technology, which is applied in the direction of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of short time consumption, long time consumption, and low demand for production line circulation speed, and achieve the effect of compact structure and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

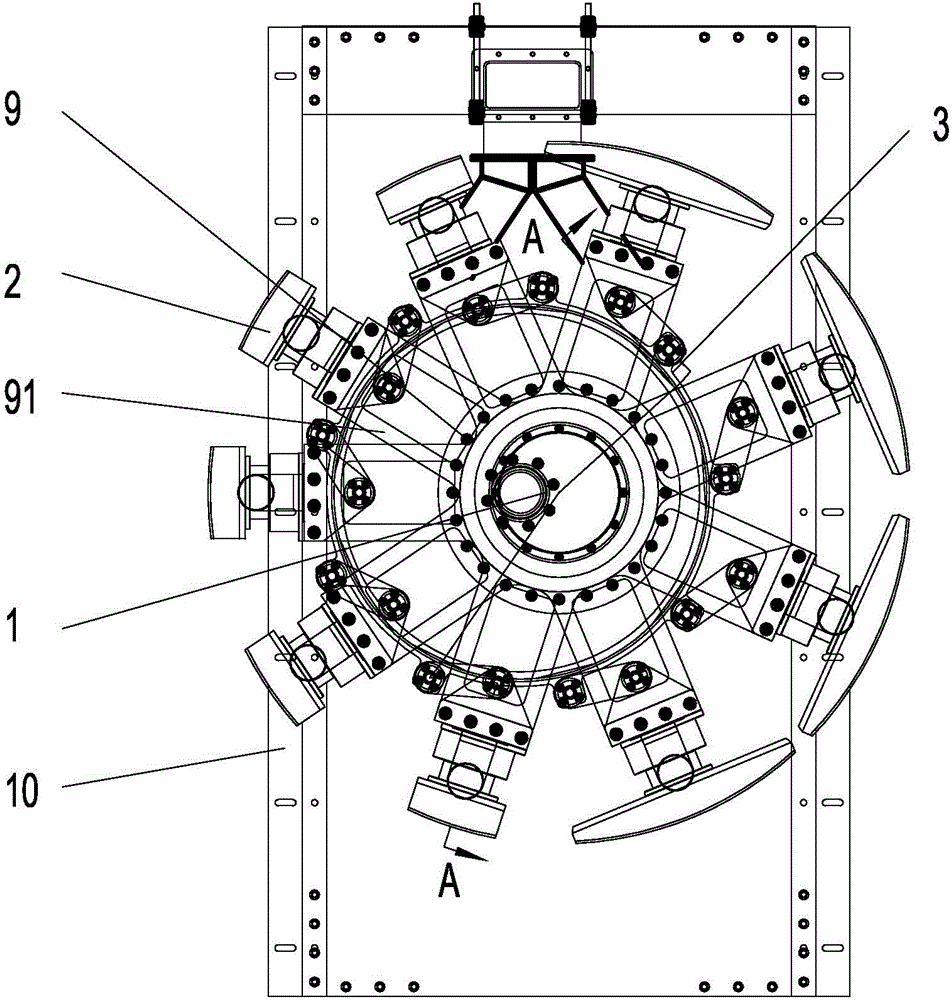

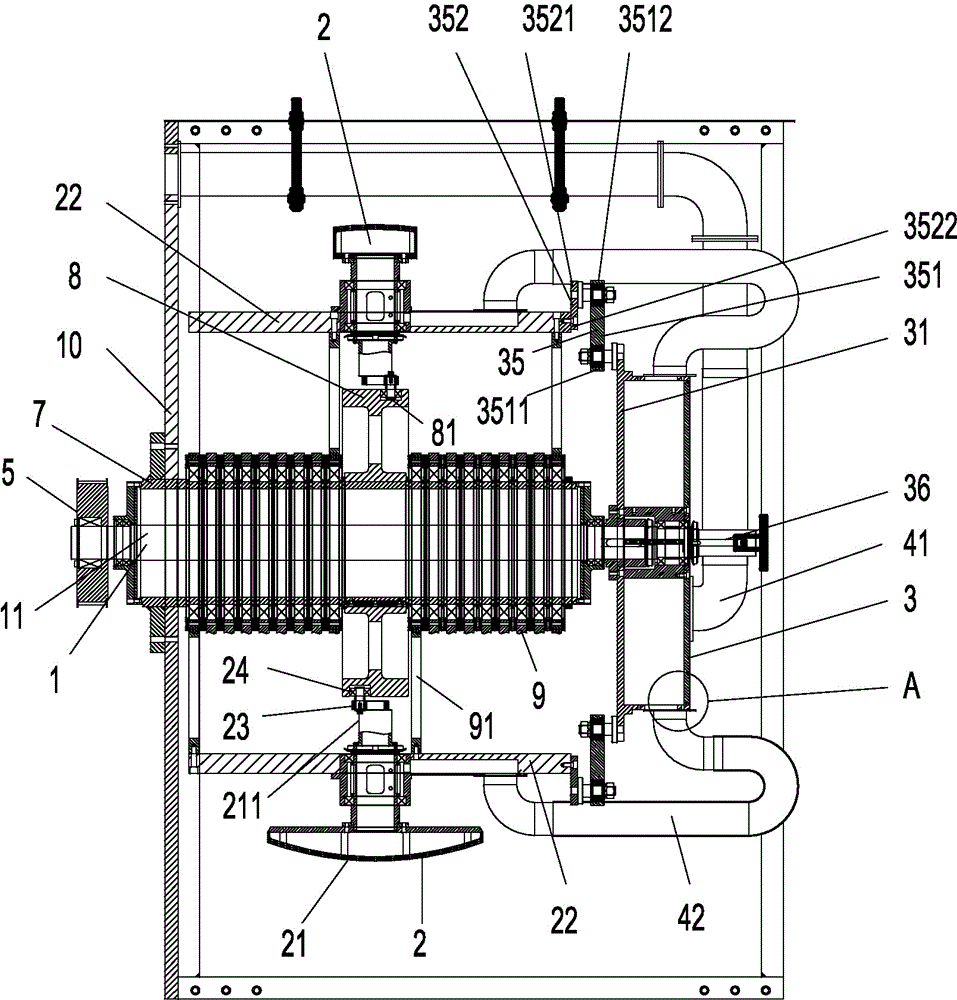

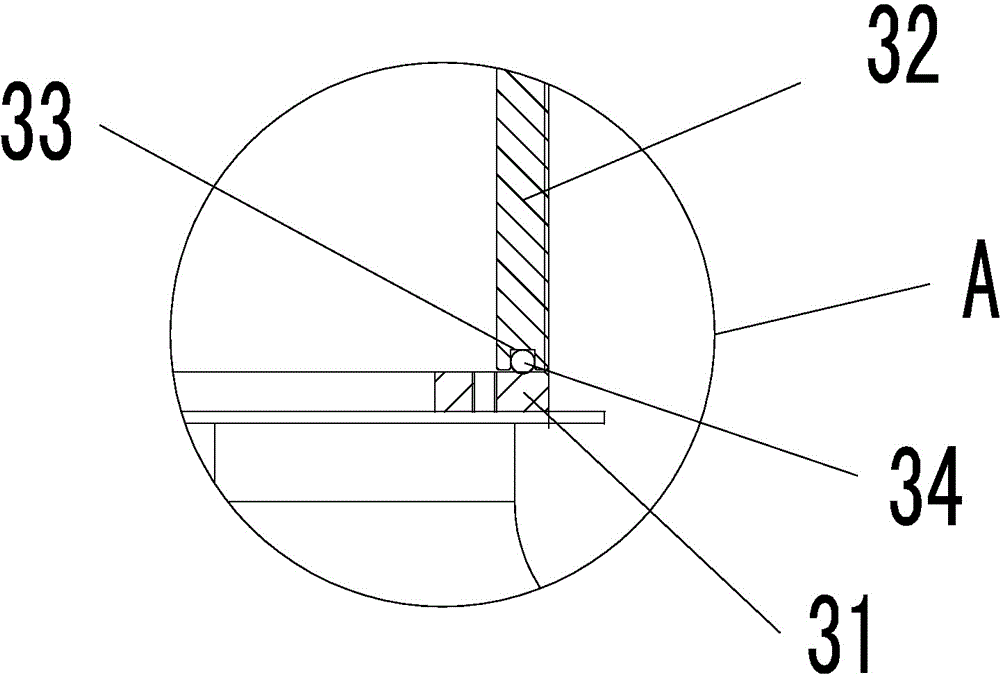

[0016] Such as Figure 1 to Figure 3 As shown, an eccentric indexing wheel device includes a frame 10, a main shaft 1, an adsorption mechanism 2, a steering mechanism and a negative pressure mechanism. At the output end 12 of the main shaft; the adsorption mechanism 2 includes a suction cup assembly 21 and an air storage block 22, the steering mechanism includes an adsorption arm 23, the air storage block 22 passes through the suction cup assembly 21 and is fixedly connected with the suction cup assembly 21, The lower end 211 of the suction cup assembly near the main shaft side is equipped with an adsorption arm 23; the negative pressure mechanism includes a turntable 3, and a support sleeve 7 is eccentrically sleeved on the outer side of the main shaft between the synchronous wheel 5 and the turntable 3, the support The sleeve 7 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com