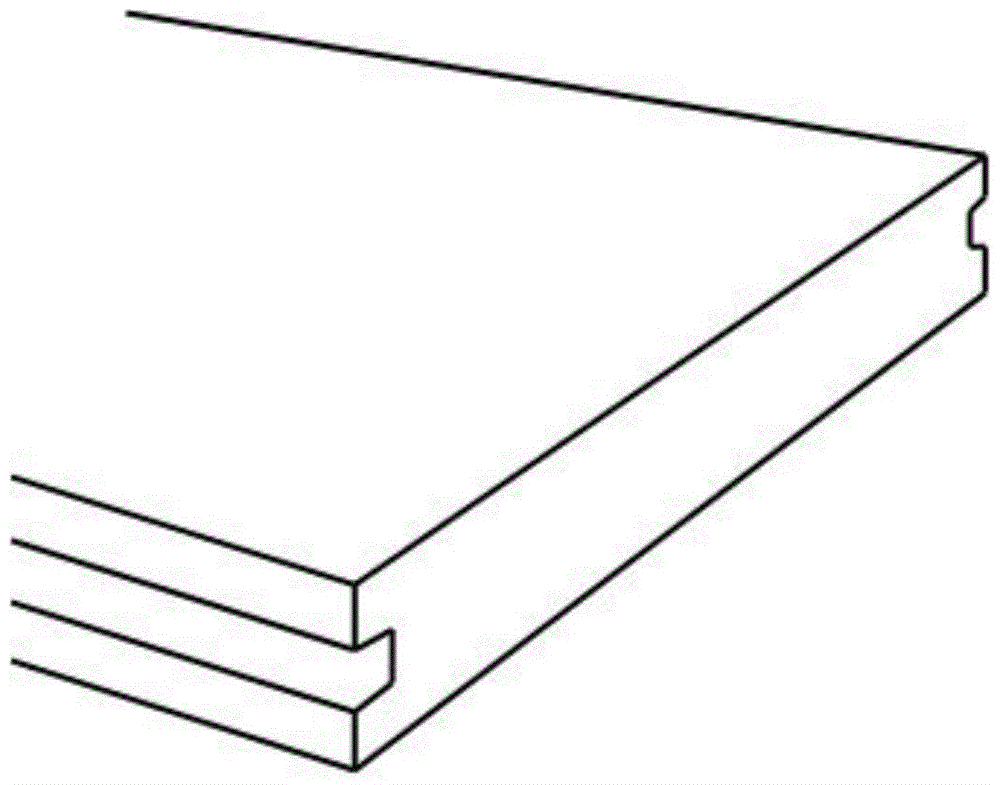

An outdoor high-weather resistance high-strength co-extruded wood-plastic composite floor and its manufacturing process

A compound flooring and manufacturing process technology, applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problems of high processing cost, poor aging resistance, unsuitable use, etc., to reduce costs, improve strength, reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

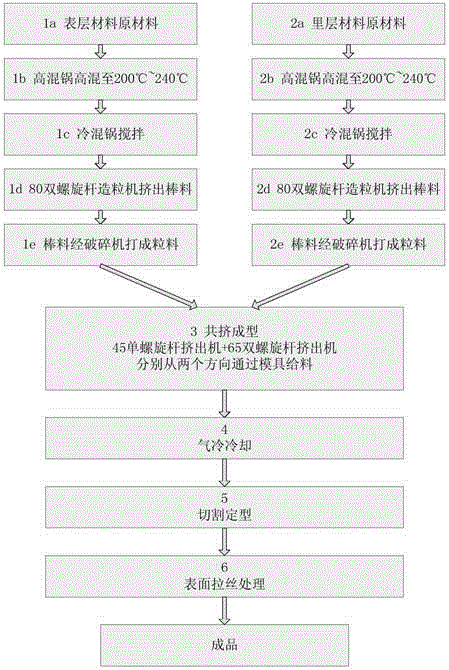

Method used

Image

Examples

Embodiment 1

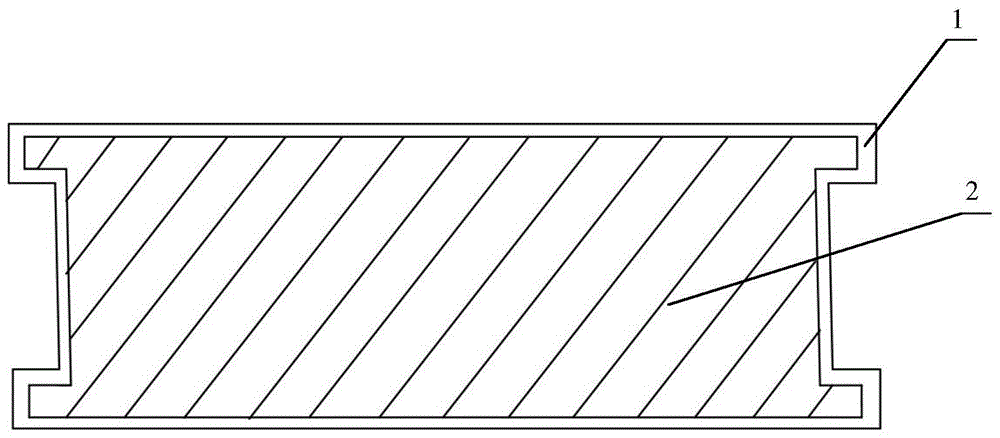

[0047] A high-strength co-extruded plastic-wood composite floor comprises a surface layer and an inner layer. Its surface layer is composed of the following components: 46 parts by weight of pp, 30 parts by weight of modified resin, 8 parts by weight of hardwood powder of 120 mesh, 2 parts by weight of calcium carbonate, 2.5 parts by weight of talcum powder, anti-UV agent (brand 151) 0.1 parts by weight, 10100.2 parts by weight of antioxidant, 0.5 parts by weight of white oil, 1.2 parts by weight of maleic anhydride grafted pp, 2 parts by weight of PE wax, 0.3 parts by weight of EBS, 0.8 parts by weight of zinc stearate, 2.4 parts by weight of toner The inner layer is composed of the following components: 32 parts by weight of HDPE, 35 parts by weight of 120 mesh hardwood powder, 2.5 parts by weight of coupling agent, 6 parts by weight of calcium carbonate, 18 parts by weight of glass fiber, and 2 parts by weight of PE wax , EBS 0.1 weight part, zinc stearate 0.5 weight part. ...

Embodiment 2

[0050] A high-strength co-extruded plastic-wood composite floor comprises a surface layer and an inner layer. Its surface layer is composed of the following components: 53 parts by weight of pp, 36 parts by weight of modified resin, 12 parts by weight of 120 mesh hardwood powder, 4 parts by weight of calcium carbonate, 4 parts by weight of talcum powder, anti-UV agent (brand 151) 0.3 parts by weight, 0.3 parts by weight of antioxidant 1010 and antioxidant 168 mixed, 1.2 parts by weight of white oil, 3.6 parts by weight of maleic anhydride grafted pp, 1 part by weight of PE wax, 0.5 parts by weight of EBS, 1 part by weight of zinc stearate , 3.6 parts by weight of toner; the inner layer is composed of the following components: 35 parts by weight of HDPE, 42 parts by weight of 120 mesh hardwood powder, 3.6 parts by weight of coupling agent, 12 parts by weight of calcium carbonate, and 25 parts by weight of glass fiber , PE wax 1 weight part, EBS 0.5 weight part, zinc stearate 1 ...

Embodiment 3

[0053]A high-strength co-extruded plastic-wood composite floor comprises a surface layer and an inner layer. Its surface layer consists of the following components: 60 parts by weight of pp, 43 parts by weight of modified resin, 18 parts by weight of 120 mesh hardwood powder, 6 parts by weight of calcium carbonate, 8 parts by weight of talcum powder, anti-UV agent (brand 151) 0.7 parts by weight, 1680.5 parts by weight of antioxidant, 2.6 parts by weight of white oil, 4.2 parts by weight of maleic anhydride grafted pp, 2 parts by weight of PE wax, 1.2 parts by weight of EBS, 1.8 parts by weight of zinc stearate, 5 parts by weight of toner The inner layer is composed of the following components: 45 parts by weight of HDPE, 55 parts by weight of 120 hardwood powder, 5.2 parts by weight of coupling agent, 18 parts by weight of calcium carbonate, 32 parts by weight of glass fiber, and 2.2 parts by weight of PE wax , EBS 1 weight part, zinc stearate 2 weight parts.

[0054] The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com