Support roll bilateral direct transmission gear of four-roll plate and strip rolling mill

A transmission device and back-up roll technology, applied in the direction of the drive device for metal rolling mills, metal rolling, metal rolling, etc., can solve the problems of accelerating roll surface wear, increasing strip thickness error, and low torque transmission efficiency. Achieve the effect of increasing the life of the roll, improving the quality of the rolled piece, and improving the quality of the plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

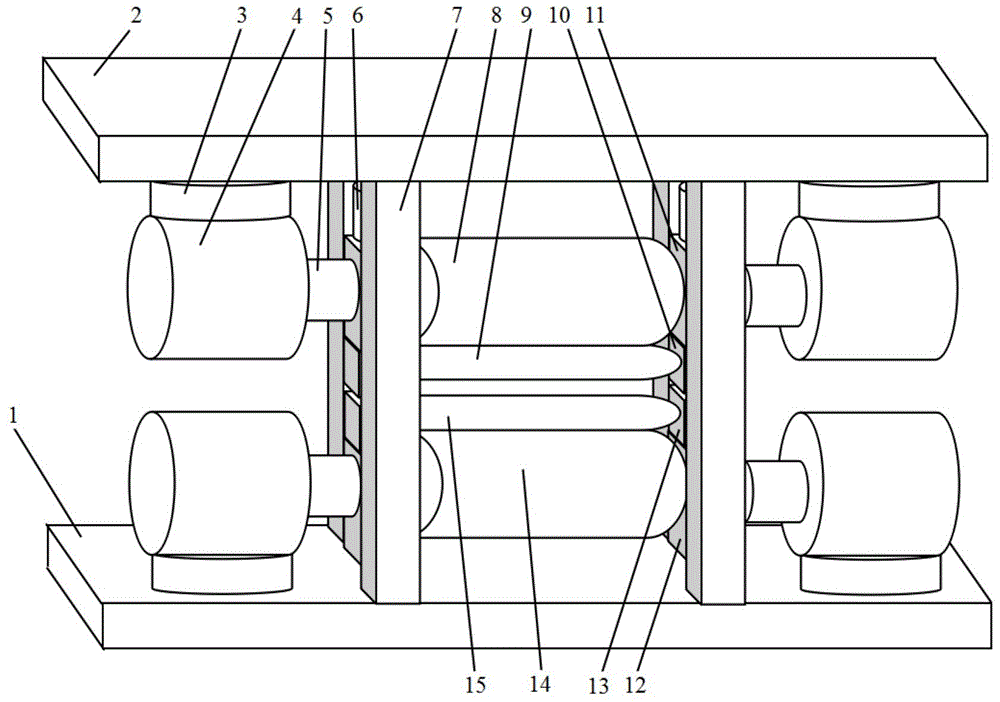

[0010] Such as figure 1 As shown, a double-sided direct transmission device for back-up rolls of a four-roll strip mill, the device is a fully symmetrical structure up and down, left and right, consisting of a frame base 1, a frame upper cover plate 2, and four motor balance cylinders 3 , four motors 4, four couplings 5, two pressure hydraulic cylinders 6, four rack columns 7, one upper backup roll 8, one upper work roll 9, two upper work roll bearing housings 10, two One upper back-up roll chock 11, two lower back-up roll chocks 12, two lower work roll chocks 13, one lower back-up roll 14 and one lower work roll 15, the four frame columns 7, one machine The upper cover plate 2 and a frame base 1 form a rolling mill frame, two hydraulic cylinders for pressing down 6, one upper back-up roll 8 and two upper back-up roll bearing housings 11, one upper work roll 9 and two upper work rolls Bearing housing 10, one lower working roll 15, two lower working roll bearing housings 13, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com