Aluminium alloy multi-layer filter tank

A technology of filter box and aluminum alloy, which is applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of multiple filtration, trouble, and influence on service life, and achieve cleanliness, long service life, The effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

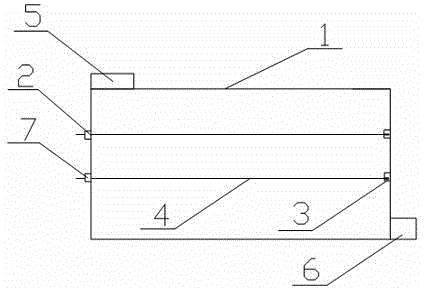

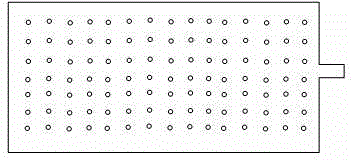

[0013] Such as Figure 1~2 The shown aluminum alloy multi-layer filter box includes a box body 1, a through hole 2 is opened on one side of the box body 1, and a grooved side wall corresponding to the through hole 2 is provided on the other side wall of the box body. The fixed block 3 of each pair of through holes 2 and its horizontally corresponding fixed block 3 are fixed with a filter plate 4, the top of the box body 1 is provided with a water inlet 5, and the bottom is provided with a water outlet 6; the filter plate The number of 4 is 2 pieces, and one end of the filter plate 4 has a protrusion, and the protrusion can pass through the through hole on the side of the box body, the filter plate has a through hole, and the through hole of the upper filter plate is larger than the small filter plate; The raised end of the filter plate 4 located on the outside of the box is covered with a waterproof rubber ring 7, and the diameter of the rubber ring 7 is larger than the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com