Boletus edulis Maillard flavor peptide and preparation method thereof

A technology of umami peptide and boletus, which is applied in food preparation, food science, protein-containing food ingredients, etc., can solve the problems that more is better, and achieve the effects of improving the sense of penetration, simple and controllable preparation process, and natural flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

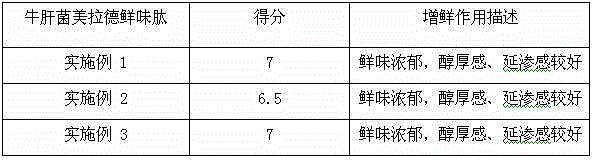

Embodiment 1

[0029] Embodiment 1: The preparation method of the boletus Maillard umami peptide, the specific operations are as follows:

[0030] (1) Processing of boletus

[0031] Take 1kg of fresh boletus, scrape off the soil on the stipe and cap with a knife, wash the sediment with clean water, rinse with dilute salt water with a mass percentage concentration of 0.4%, drain the water, put it into a beater and add water Homogenize, remove all and set aside;

[0032] (2) Preparation of boletus enzymatic hydrolyzate

[0033] Add 0.15% flavor protease, 0.15% cellulase, 0.1% neutral protease and 0.1% chitinase to the boletus slurry for enzymolysis, stir, and heat to 50°C. Continue the enzymatic hydrolysis for 1.5 hours. After the enzymatic hydrolysis is completed, raise the temperature to 100°C and keep it for 15 minutes to inactivate the enzyme and obtain the enzymatic hydrolysis product. After cooling, centrifuge at 5000r for 20 minutes to separate the supernatant from the bac...

Embodiment 2

[0040] Embodiment 2: The preparation method of the boletus Maillard umami peptide, the specific operations are as follows:

[0041] (1) Processing of boletus

[0042] Get the leftover material 1Kg that boletus produces in the processing process, scrape off the soil on the stipe and the cap with a knife, wash the silt with clear water, then use the mass percent concentration to rinse with 0.5% dilute salt water, drain the moisture, Put it into a beater and add water to homogenize it, and take it all out for later use;

[0043] (2) Preparation of boletus enzymatic hydrolyzate

[0044]Add 0.20% flavor protease, 0.20% cellulase, 0.13% neutral protease and 0.13% chitinase to the boletus slurry for enzymolysis, stir, and heat to keep at 60°C , continue the enzymatic hydrolysis for 1 hour, after the end of the enzymatic hydrolysis, raise the temperature to 90°C and keep for 30 minutes to inactivate the enzyme, obtain the enzymatic hydrolysis product, cool, centrifuge at 4000r f...

Embodiment 3

[0051] Embodiment 3: The preparation method of the boletus Maillard umami peptide, the specific operation is as follows:

[0052] (1) Processing of boletus

[0053] Mix 1 kg of fresh boletus and its leftovers produced during processing, scrape off the soil on the stipe and cap with a knife, wash the sediment with clear water, and then rinse with dilute salt water with a concentration of 0.6% by mass , drain the water, put it into a beater, add water to homogenize it, and take it all out for later use;

[0054] (2) Preparation of boletus enzymatic hydrolyzate

[0055] Add 0.24% flavor protease, 0.24% cellulase, 0.16% neutral protease and 0.16% chitinase to the boletus slurry for enzymolysis, stir, and keep heated at 55°C In between, the enzymolysis was continued for 2 hours. After the enzymolysis was completed, the temperature was raised to 95°C and kept for 10 minutes to inactivate the enzyme to obtain the enzymatic hydrolysis product, which was cooled and centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com