A directional cutting machine for sprouts

A technology for sprouts and cutting machines, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as uneven bundles, increased difficulty in bundle packaging, inability to meet work efficiency and tidy bundles, etc. The effect of tidying and improving the efficiency of bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

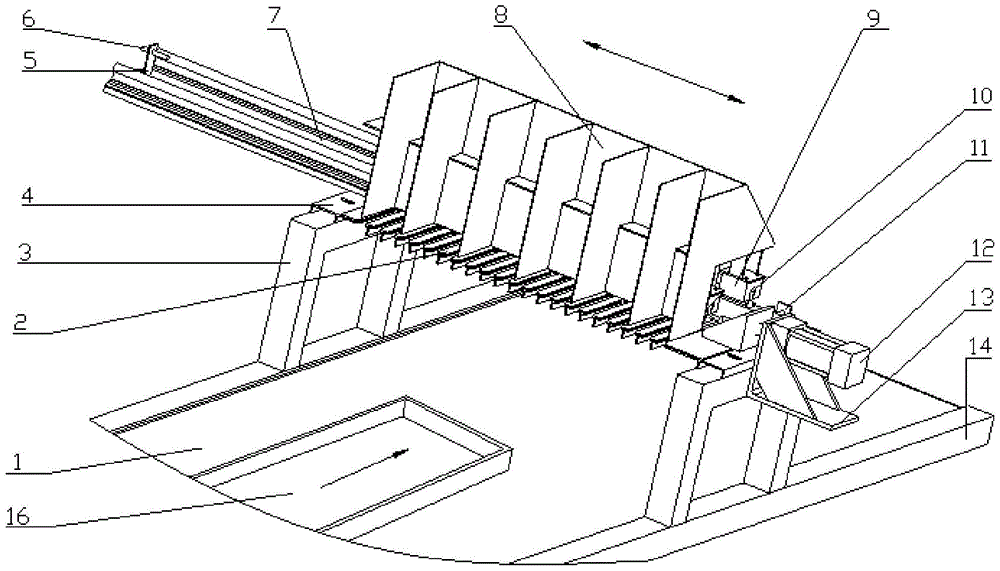

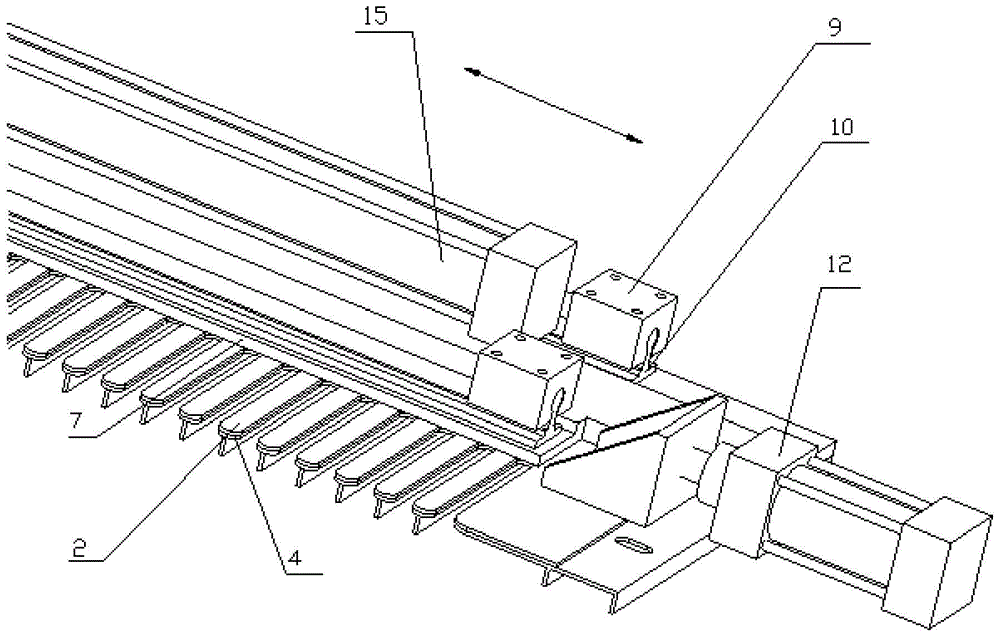

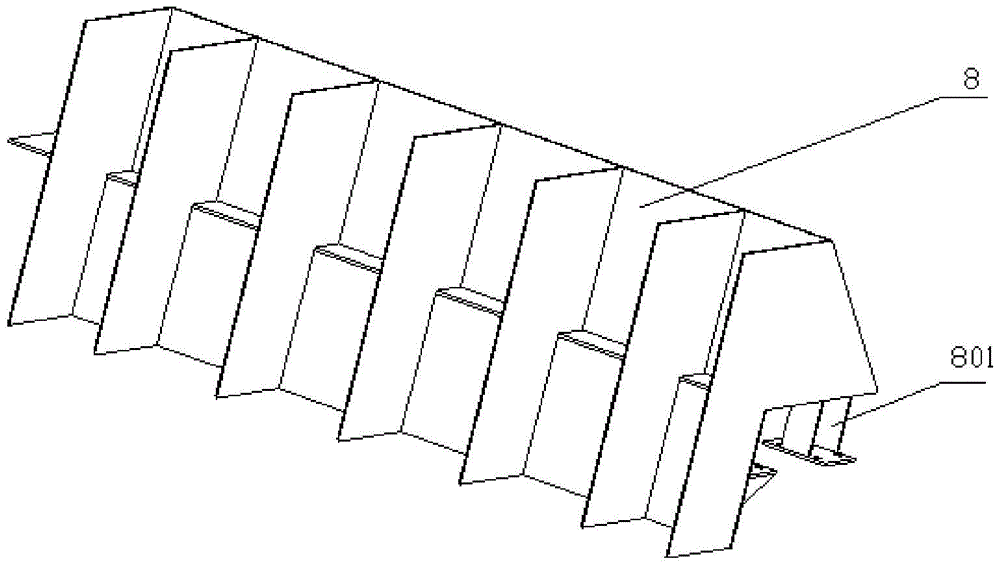

[0020] see figure 1 , figure 2 and image 3 , the structural form of the sprout vegetable directional cutting machine in the present embodiment is:

[0021] Slope conveyor 14 is vertically set, and the conveyor belt 1 in the slope conveyor 14 is downhill along the delivery direction of the sprout dish 16; Above the conveyor belt 1, the conveyor belt 1 is set across the conveyor belt 1 and the gantry 3 is set. A shearing unit is arranged on the gantry 3, and the shearing unit is composed of a movable blade 2 and a fixed blade 4, the movable blade 2 and the fixed blade 4 are finger blades, and the direction of the middle finger of the finger blade faces the feeding of the sprout dish direction; the fixed blade 4 is a fixed blade, and the fixed blade 4 is arranged on the gantry parallel to the slope surface of the slope conveyor 14; The blade 4 moves back and forth, and forms shear together with the fixed blade 4 .

[0022] figure 1 , figure 2 and image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com