Cocoon stripping bed structure

A technology for removing cocoons and installing holes, applied in animal husbandry, etc., can solve the problems of low cocoon harvesting efficiency and high labor intensity of silkworm farmers, and achieve high operating efficiency and avoid the effect of silkworms falling off and connecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

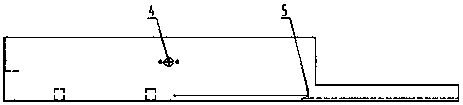

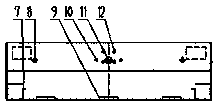

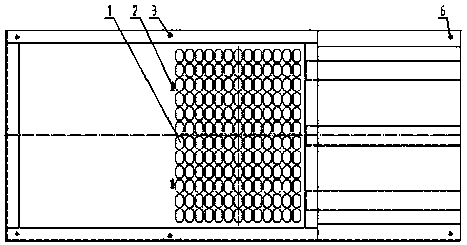

[0015] Such as figure 1 , figure 2 , image 3 As shown, a cocoon-removing bed structure includes cocoon leakage hole 1, bar hole 2, lower limiter II installation hole 3, upper limiter I installation hole 4, support wheel installation hole 5, rack connection hole 6, and card position Sheet 7, optical axis mounting hole 8, clamping block 9, bearing seat mounting hole 10, screw rod through hole 11, motor mounting hole 12. The bottom plate of the cocoon-removing bed is provided with cocoon leaking hole 1 equal to the grid of the grid cluster, cocoon cluster card slot sheet entry and exit hole 2, lower limiter II installation hole 3 and frame connection hole 6, and three card slots are fixed on the right end of the bottom plate Block 9; upper limiter installation hole 4 and support wheel installation hole 5 are respectively opened on the two side panels of the cocoon removal bed; two optical axis installation holes 8 and screw bearing seat installation holes are respectively ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com