Large-scale motor stator bar anti-corona structure capable of improving voltage resistance level of windings

An anti-corona structure and stator bar technology, applied in the shape/style/structure of winding insulation, can solve the problems of limited function of winding bars, reduce the winding gap electric field, ensure consistency, and improve winding withstand voltage horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An anti-corona structure for a stator bar of a large motor that improves the withstand voltage level of a winding is characterized in that it specifically includes:

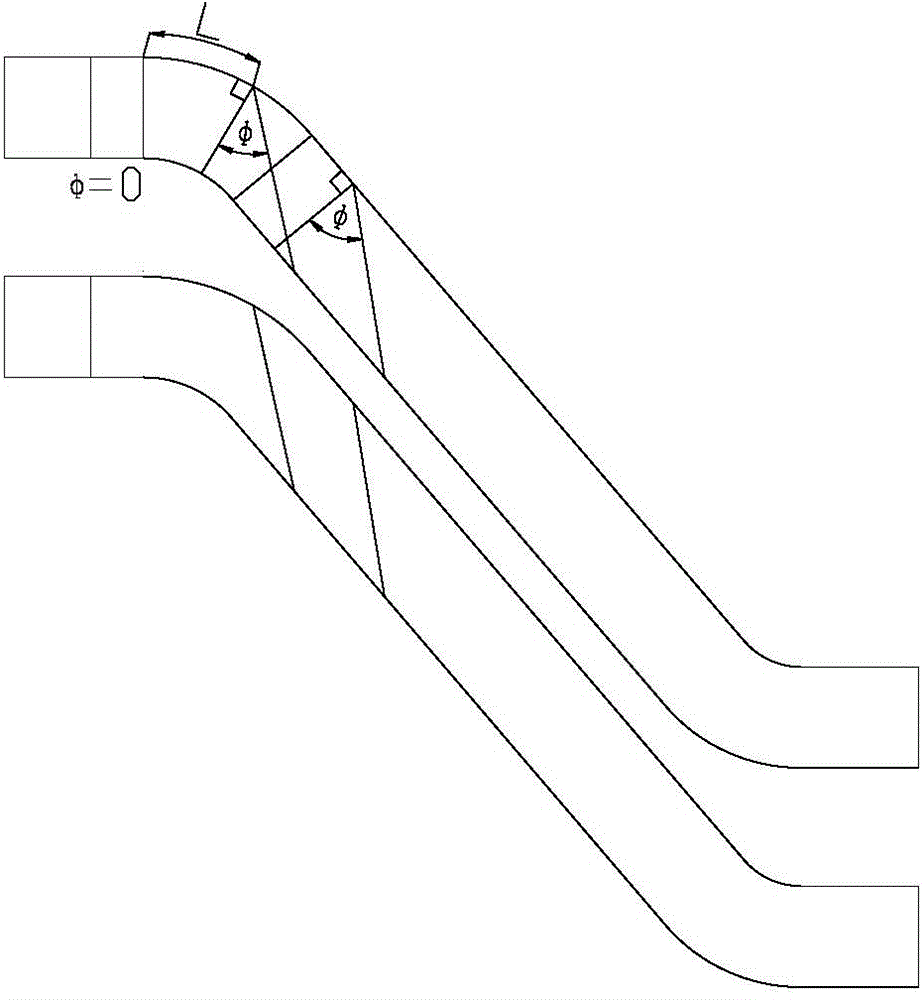

[0020] (1) if figure 1 As shown, the geometric structure of the three sections of the stator bar is: the first section of the beginning straight line 1, the second section of the corner 2 and the third section of the hypotenuse straight line 3 structure, the bar rotation angle θ, the corner radius R, the bar section height h, The gap d between the hypotenuses of the wire rods, the distance L from the beginning of the corner of the wire rods to the anti-halation lap;

[0021] (2) if figure 2 As shown, the different geometric positions of the anti-halation lap wire rods, φ are respectively: the distance from the first straight line at the beginning of the first segment, the beginning of the corner of the wire rod to the anti-halation lap joint is a negative value, when L≤0, such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com