a kind of fe 78 the si 9 b 13 Method for increasing saturation magnetization and reducing coercive force of amorphous crystals

A technology of magnetization and coercivity, which is used in inductor/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve problems such as poor temperature control, and achieve low cost, simple magnetic performance, and easy operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

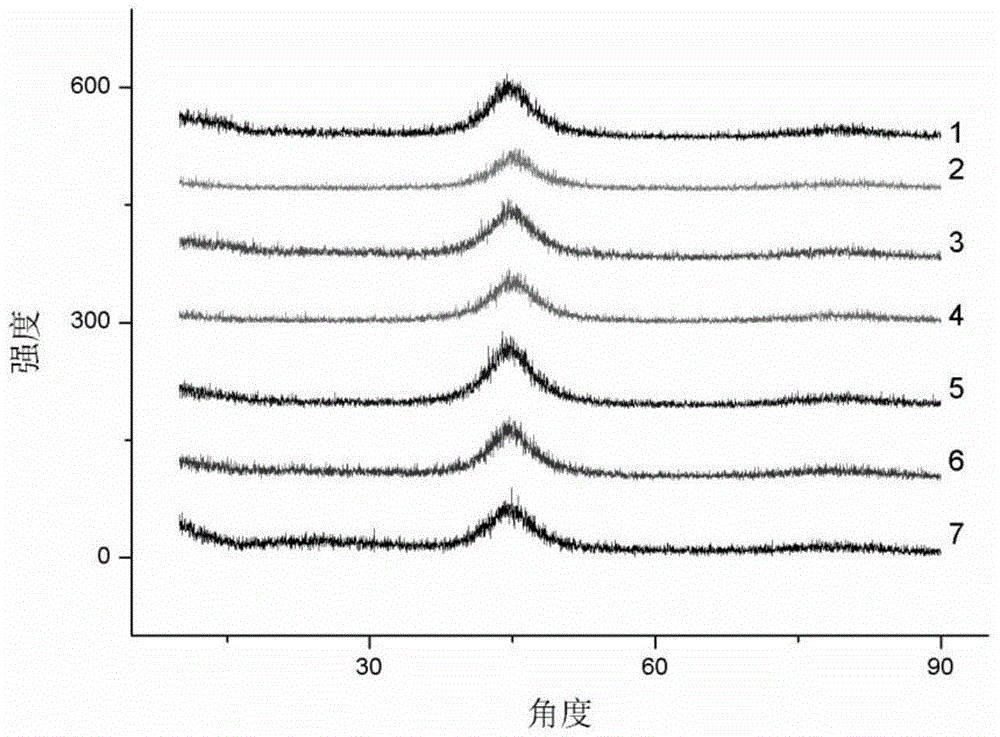

[0027] A kind of Fe 78 Si 9 B 13 The method for the rapid improvement of amorphous magnetic properties (saturation magnetization enhancement and coercive force reduction) comprises the following steps:

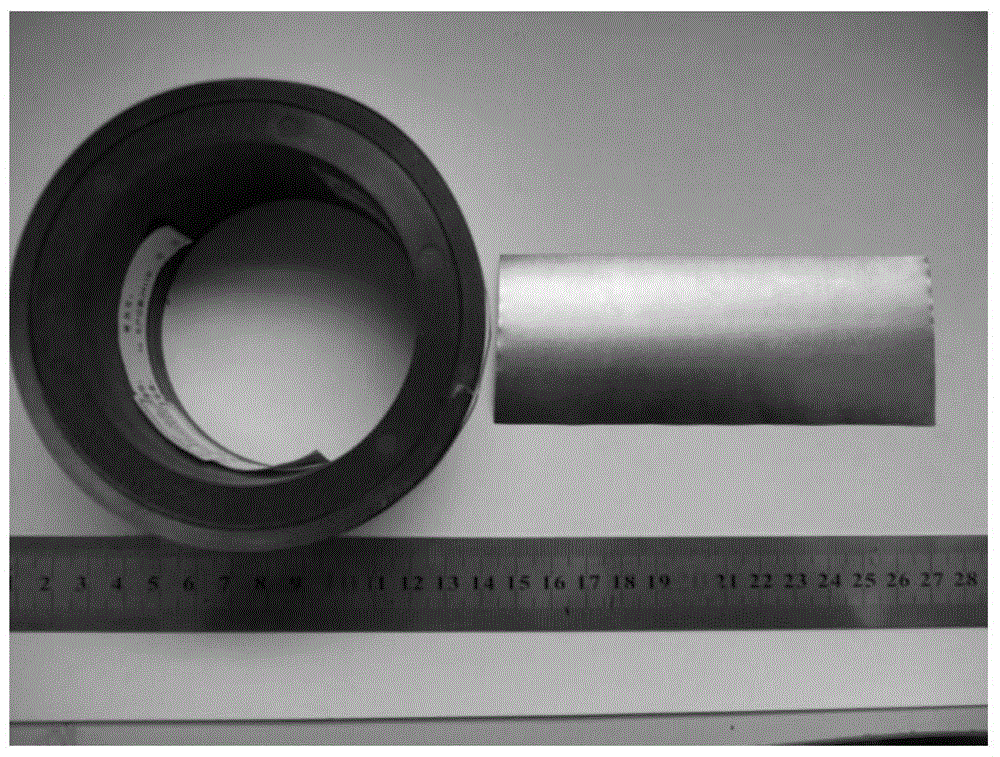

[0028] Step one, the Fe 78 Si 9 B 13 Cut the amorphous into strips with a length of a=5cm and a width of b=3mm, and put them into a sample bag as a spare sample.

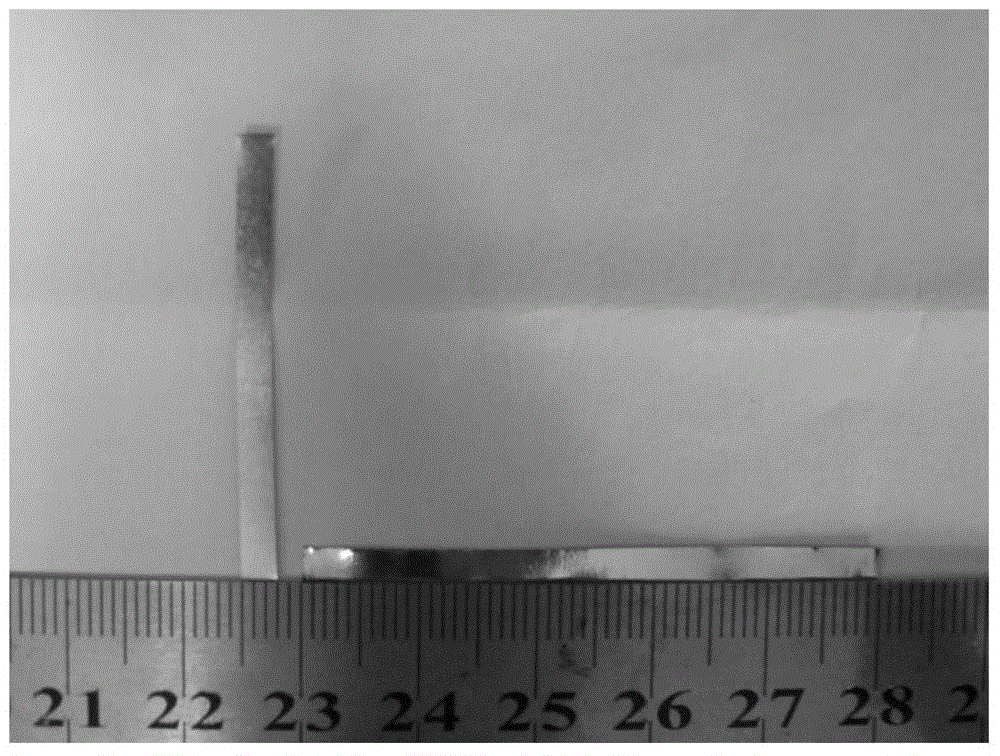

[0029] Step 2, set the constant current of the power supply to 1.5A.

[0030] Step 3, the power cord is connected to both ends of the strip, and the timer is ready to count.

[0031] Step 4, turn on the power supply to pass the current, and start timing at the same time.

[0032] Step five, turn off the power when the power-on time reaches 100s, and remove the strip.

Embodiment 2

[0034] A kind of Fe 78 Si 9 B 13 The method for the rapid improvement of amorphous magnetic properties (saturation magnetization enhancement and coercive force reduction) comprises the following steps:

[0035] Step one, the Fe 78 Si 9 B 13 Cut the amorphous into strips with a length of a=5cm and a width of b=3mm, and put them into a sample bag as a spare sample.

[0036] Step 2, set the constant current of the power supply to 1.65A.

[0037] Step 3, the power cord is connected to both ends of the strip, and the timer is ready to count.

[0038] Step 4, turn on the power supply to pass the current, and start timing at the same time.

[0039] Step five, turn off the power when the power-on time reaches 100s, and remove the strip.

Embodiment 3

[0041] A kind of Fe 78 Si 9 B 13 The method for the rapid improvement of amorphous magnetic properties (saturation magnetization enhancement and coercive force reduction) comprises the following steps:

[0042] Step one, the Fe 78 Si 9 B 13 Cut the amorphous into strips with a length of a=5cm and a width of b=3mm, and put them into a sample bag as a spare sample.

[0043] Step 2, set the constant current of the power supply to 1.8A.

[0044] Step 3, the power cord is connected to both ends of the strip, and the timer is ready to count.

[0045]Step 4, turn on the power supply to pass the current, and start timing at the same time.

[0046] Step five, turn off the power when the power-on time reaches 100s, and remove the strip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com