System for testing friction resistance of carbon dioxide anhydrous fracturing fluid

A technology of anhydrous fracturing fluid and carbon dioxide, applied in the direction of measuring devices, flow characteristics, instruments, etc., to achieve the effect of preventing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

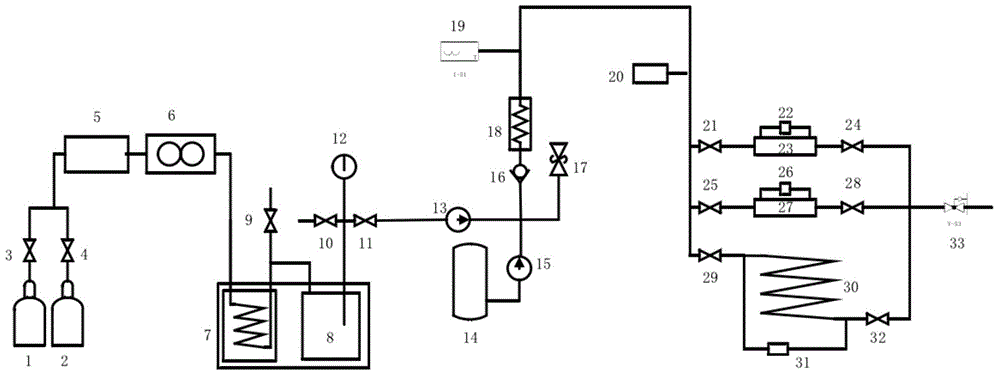

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] As shown in the accompanying drawings, the present invention includes a first gas cylinder 1 and a second gas cylinder 2. After the gas from the first gas cylinder 1 and the second gas cylinder 2 passes through the first valve 3 and the second valve 4 respectively, it passes through the purifier 5 After purification, flow is measured by flow meter 6. Then the carbon dioxide is refrigerated and liquefied by the refrigeration unit 7 2 Pump 13 enters the pipeline.

[0029] Wherein the refrigerating device 7 is connected with a third valve 9 and a fourth valve 10 to facilitate emptying and cleaning. Manometer 12 can measure liquid CO 2 internal pressure of the tank.

[0030] Another branch: put the prepared chemical reagent into the reagent tank 14 with appropriate solvent, and the reagent is input into the pipeline and CO by the reagent pump 15 2 mix. CO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com