High-stiffness guide structure

A guiding structure, high rigidity technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., to ensure the stability and reliability of load, simple structure, and reliable guiding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

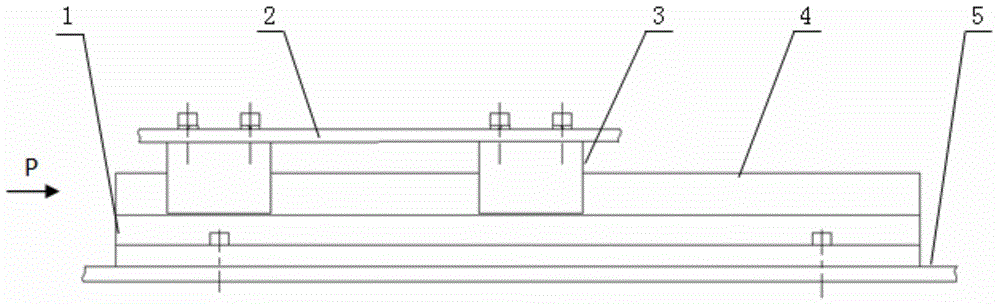

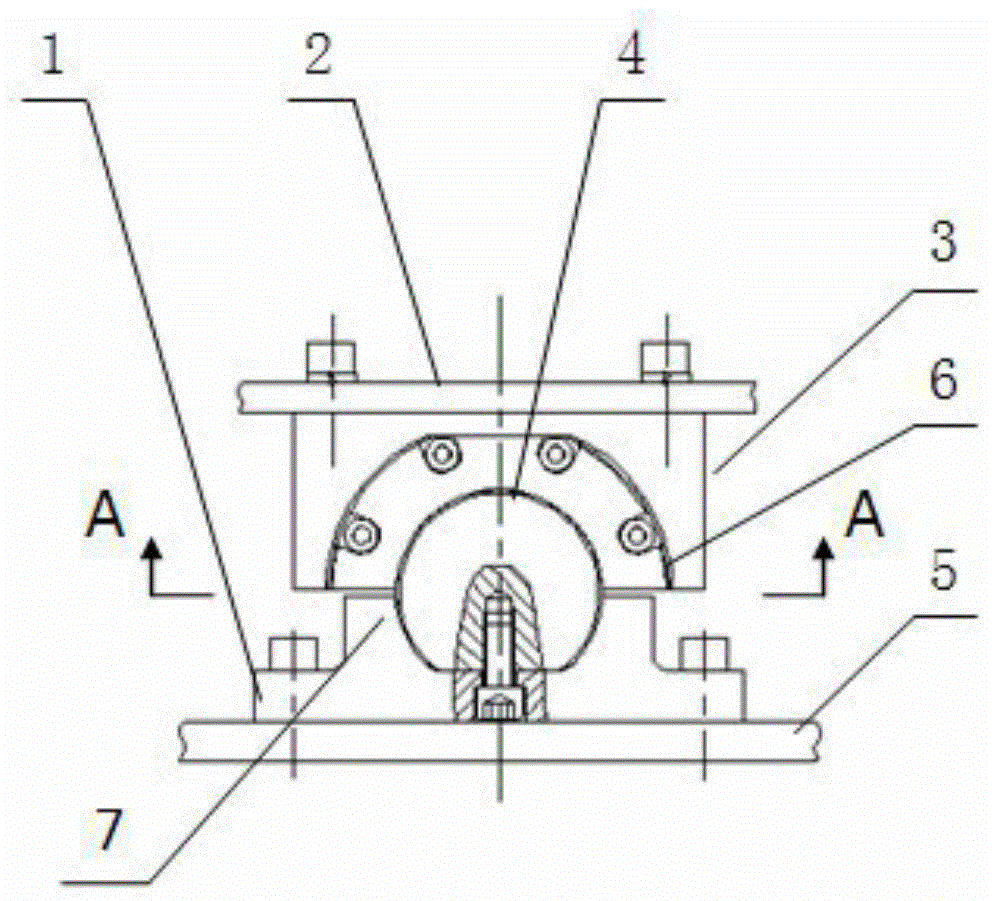

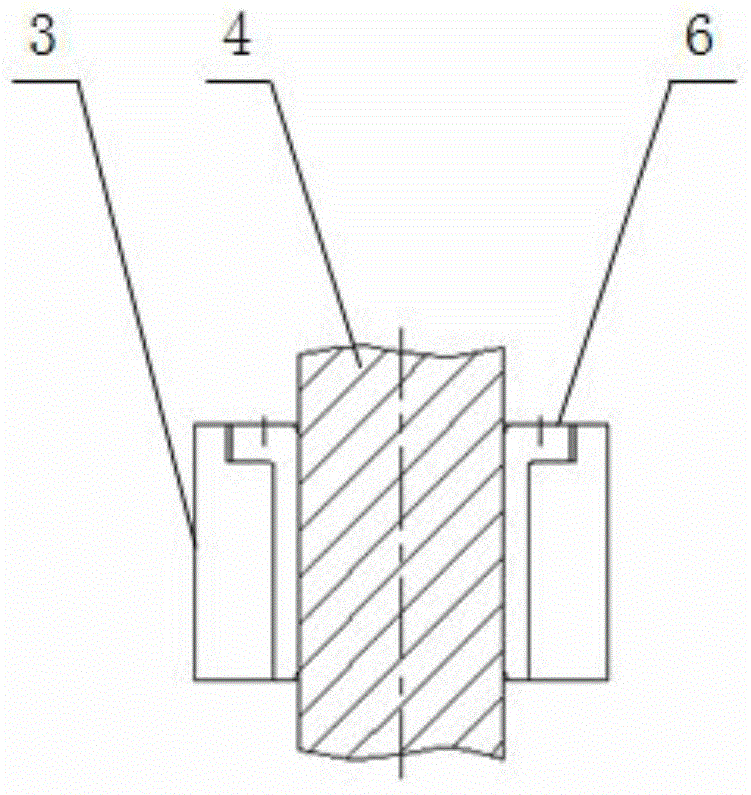

[0014] like figure 1 , figure 2 as well as image 3 As shown, a high-rigidity guide structure includes an optical axis 4, and the optical axis 4 is used as a guide shaft, and the reliability of fixing needs to be ensured to prevent its rotation and axial slippage. Specifically, a certain number of evenly distributed threaded holes are processed along the axial centerline on the rectangular section formed after the longitudinal section from the axial eccentricity of the optical axis 4, and the longitudinal section is connected with the support of the shaft support 1 The surfaces are fitted together and locked by screws, so as to avoid the rotation and axial slippage of the optical axis 4, and ensure the stability of the guiding process of the moving part 2. There are boss structures 7 on both sides of the support surface of the shaft support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com