Expansion lock bolt

An anti-loosening bolt and expansion technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of large working tension, unaffordable, unsuitable for long-term and repeated use of nylon materials, etc., to achieve easy firming process, flexible sliding, and stop Significant effect of dynamic anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

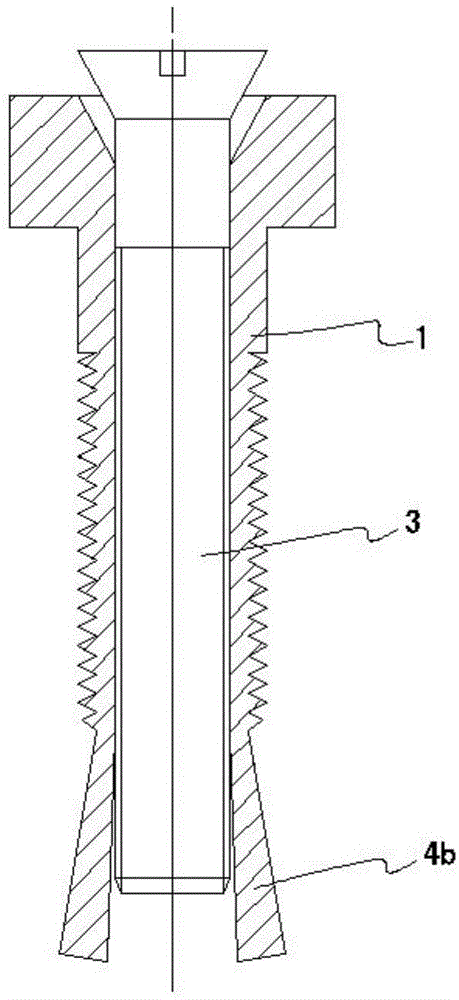

[0030] Embodiment 1: see Figure 1a , Figure 1b , Figure 1c and Figure 1d , the present embodiment is an expansion tube anti-loosening expansion bolt, which includes:

[0031] The main body bolt 1, its outer peripheral surface has an external thread structure that is threadedly matched with the internal thread hole of the workpiece, the main body bolt 1 has an internal thread hole 2 that penetrates axially, and the front section of the main body bolt 1 is set as an expansion joint that can expand radially Segment 4, the expansion segment 4 has a hollow expansion hole 5 passing through in the axial direction.

[0032] The stop bolt 3, the stop bolt 3 forms a thread fit with the internal thread hole 2 of the main body bolt 1 with its external thread, the rotation direction of the stop bolt 3 in the main body bolt 1 is the same as the rotation direction of the main body bolt 1 in the workpiece internal thread hole to the opposite direction.

[0033] The bolt front end of t...

Embodiment 2

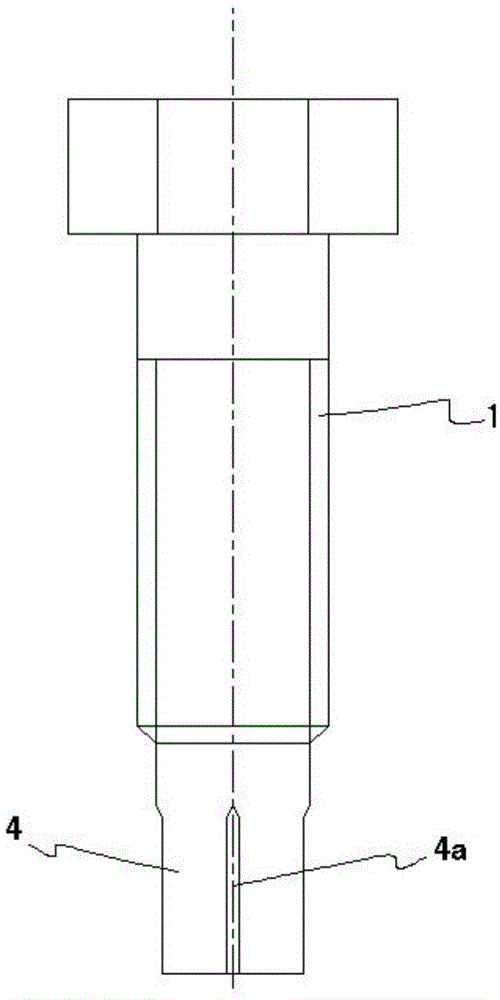

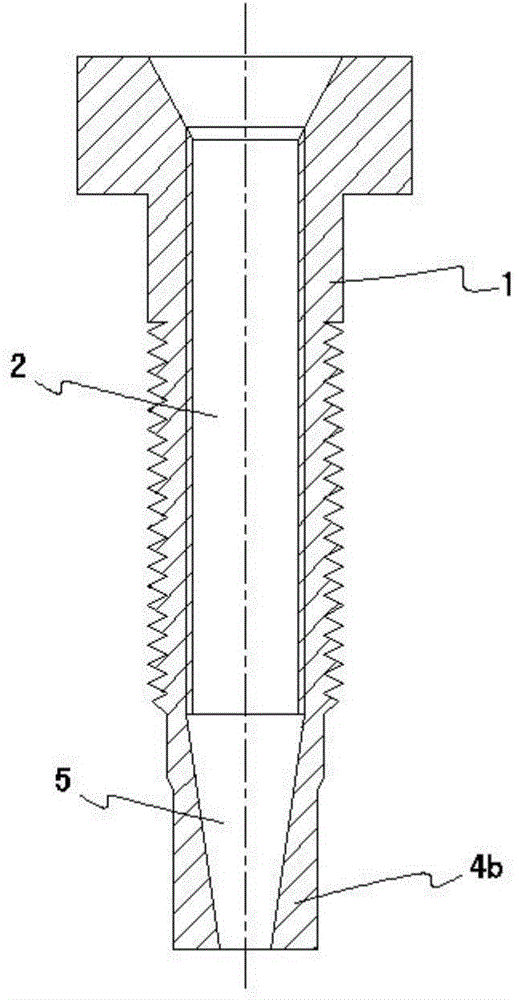

[0036] Example 2: see Figure 2a , Figure 2b , Figure 2c Figure 2d and Figure 2e , this embodiment is a slider-type anti-loosening expansion bolt, which is the same as Embodiment 1, including:

[0037] The main body bolt 1, its outer peripheral surface has an external thread structure that is threadedly matched with the internal thread hole of the workpiece, the main body bolt 1 has an internal thread hole 2 that penetrates axially, and the front section of the main body bolt 1 is set as an expansion joint that can expand radially Segment 4, the expansion segment 4 has a hollow expansion hole 5 passing through in the axial direction.

[0038] The stop bolt 3, the stop bolt 3 forms a thread fit with the internal thread hole 2 of the main body bolt 1 with its external thread, the rotation direction of the stop bolt 3 in the main body bolt 1 is the same as the rotation direction of the main body bolt 1 in the workpiece internal thread hole to the opposite direction.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com