Steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening

A technology of ultra-thick coal seams and steep inclinations, which is applied in the field of coal mining technology in steeply inclined ultra-thick coal seams, can solve the problems of low recovery rate, low mining efficiency, and many safety hazards in the working face, so as to save time, manpower and material costs, and improve mining efficiency. The effect of high efficiency and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

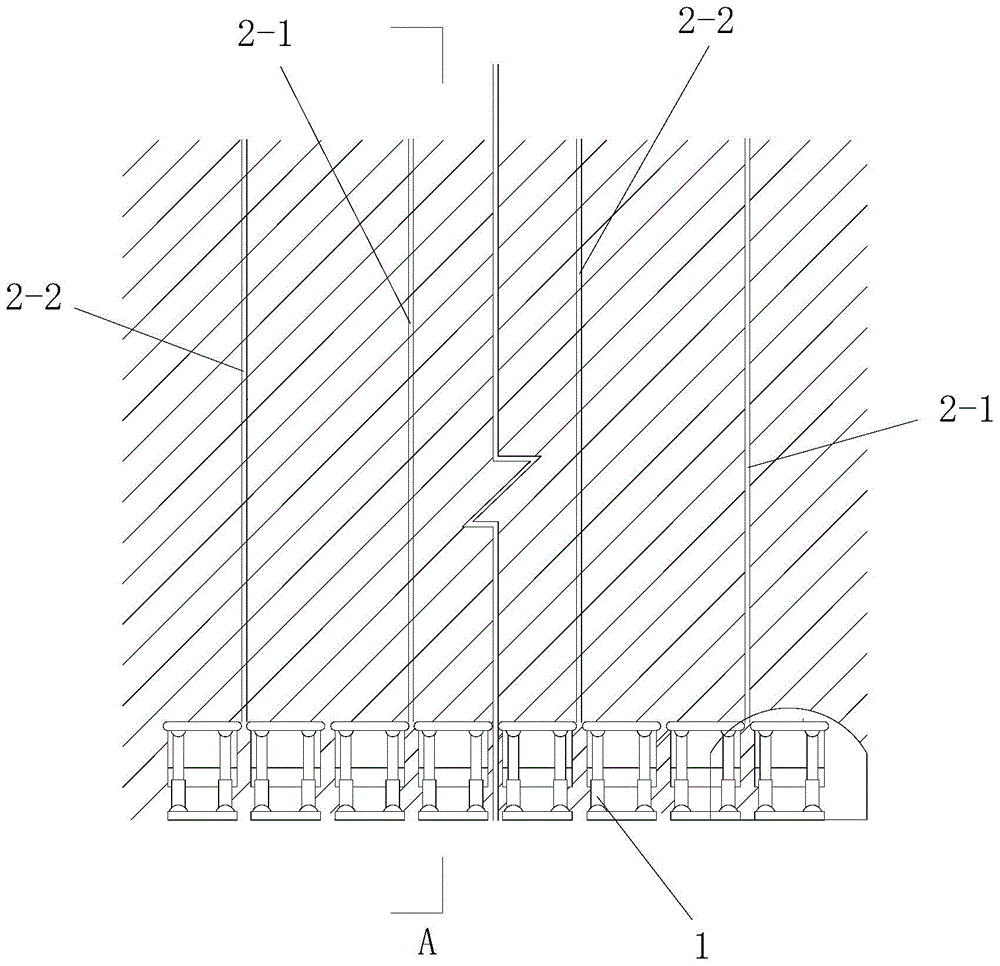

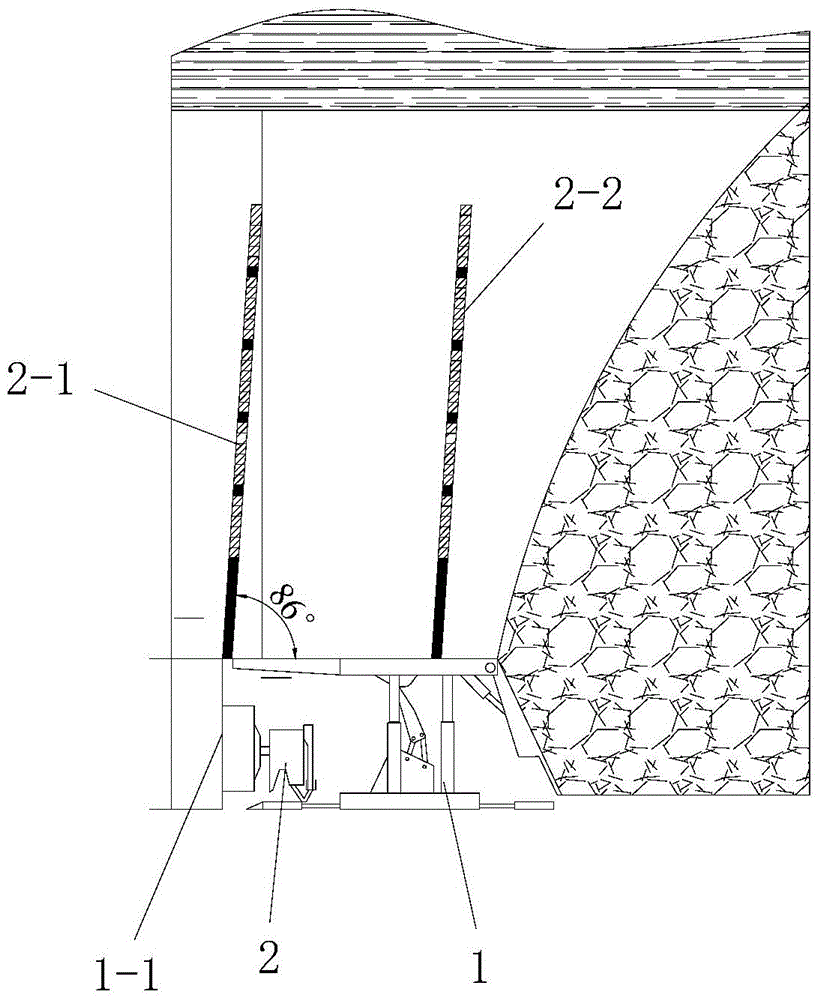

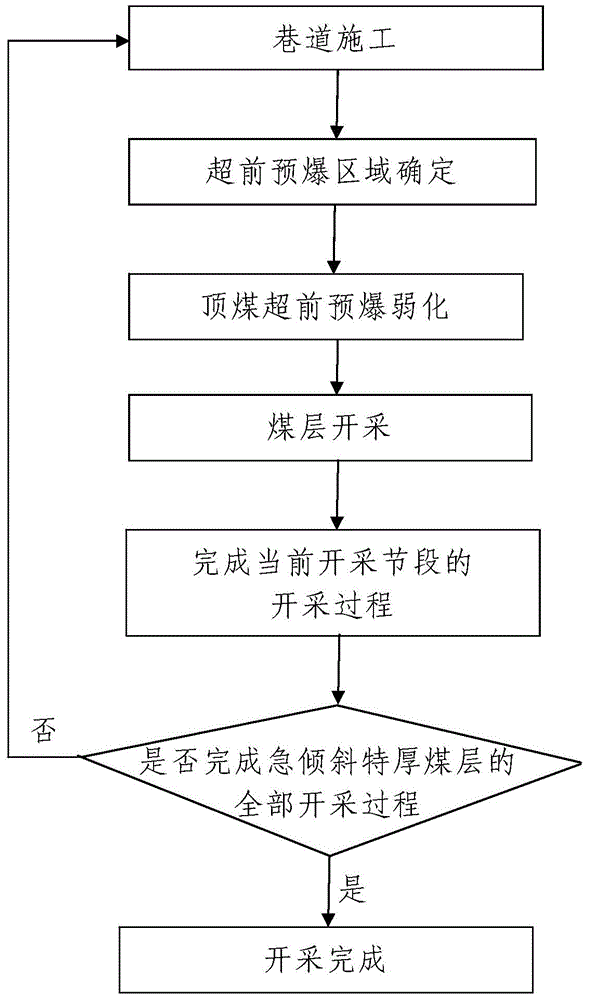

[0057] Such as figure 2 Shown a kind of steeply inclined extra-thick coal seam coal mining technology based on the weakening of top-coal advance pre-explosion, the steeply inclined extra-thick coal seam mined is a coal seam with a coal seam dip angle of more than 45° and a coal seam thickness of more than 8m; When mining a thick coal seam, the steeply inclined extra-thick coal seam is mined in multiple mining segments from back to front along the coal seam trend. The mining methods of the multiple mining segments are the same and their length along the coal seam trend All are L, wherein L=30m~50m; When a mining segment of the steeply inclined extra-thick coal seam is mined, the process is as follows:

[0058] Step 1. Roadway construction: construct a ventilation roadway on the left and right sides of the lower part of the current mining section, and the two ventilation roadways are the air inlet lane 3 and the air return lane 4 respectively.

[0059] Step 2. Top-coal advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com