Magnetron sputtering coating equipment

A magnetron sputtering coating and equipment technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the adverse effects of process repeatability, inability to achieve coating, air pressure fluctuations and other problems, to achieve The thickness of the coating is kept uniform, the effect of solving the uneven thickness of the coating and reducing the fluctuation of air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

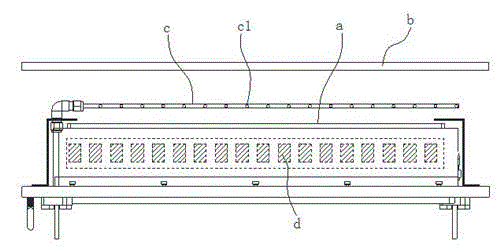

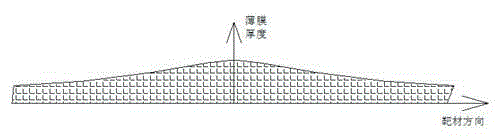

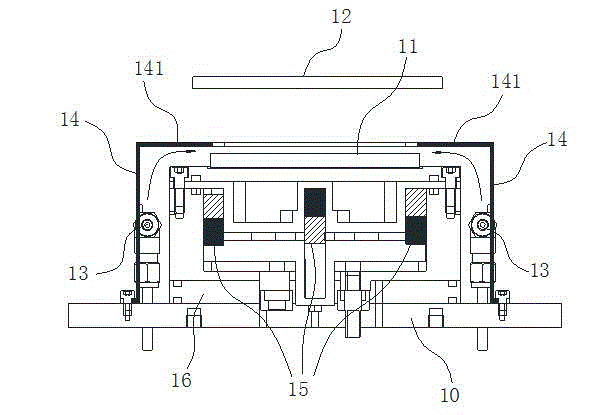

[0016] like Figure 4 As shown, a magnetron sputtering coating equipment includes a cathode target 11 horizontally arranged on a base 10, the cathode target 11 is a rectangular plate structure, a substrate 12 is arranged above the cathode target 11, and the cathode target A magnet 15 is arranged under the material 11, and the magnet 15 forms an arched magnetic field on the upper surface of the cathode target 11. The equipment also includes a gas supply unit for blowing an inert gas to the upper surface of the cathode target 11. The gas supply unit includes The gas supply pipeline arranged along the length direction of the cathode target, the gas supply pipeline 13 is provided with a plurality of air outlet holes 131 at intervals along the tube length direction, and the layout density of the gas outlet holes 131 in the middle section of the gas supply pipeline 13 is smaller than that at both ends , so that the concentration of inert gas in the middle section of the cathode targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com