Lithium ion battery cathode binder, cathode and battery

A lithium-ion battery and binder technology, applied in battery electrodes, adhesives, secondary batteries, etc., can solve the problems of poor cycle stability of lithium-ion batteries, weak adhesion of styrene-butadiene rubber, and binder failure. Good cycle stability, the effect of making up for weak adhesion and preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In the present embodiment, the percentage by weight of each component of the negative electrode material is (in terms of dry material weight):

[0057] Sodium alginate, 4.5%; styrene-butadiene rubber, 0.9%; conductive carbon black, 5%; silicon carbon negative electrode active material, 89.6%. Among them, the number average molecular weight of sodium alginate is about 500,000, and the weight ratio of sodium alginate to styrene-butadiene rubber is 5:1.

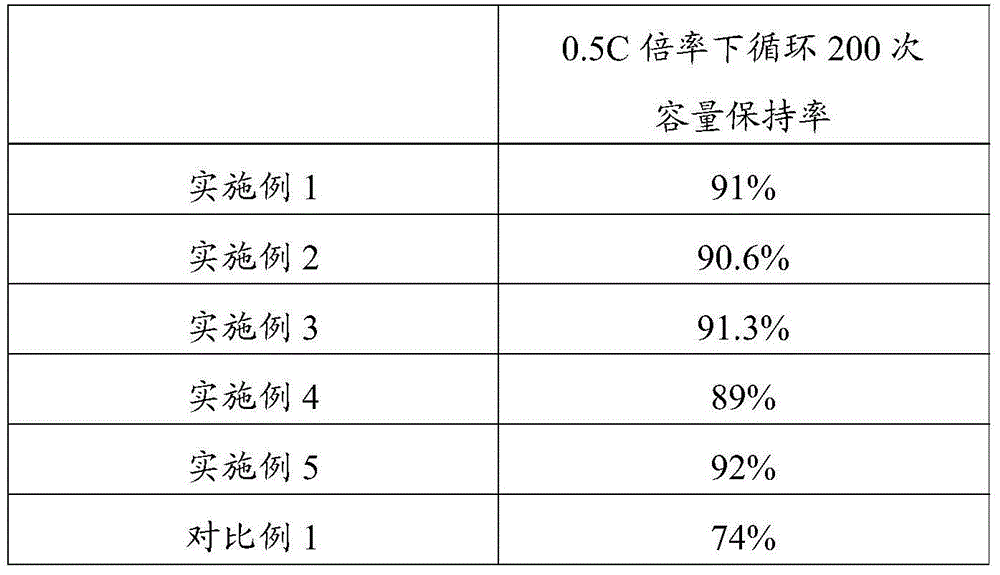

[0058] The lithium-ion battery prepared by using the above-mentioned negative electrode material was charged and discharged at a rate of 0.5C at 25°C, and the capacity retention rate was 91% after 200 cycles.

Embodiment 2

[0060] In the present embodiment, the percentage by weight of each component of the negative electrode material is (in terms of dry material weight):

[0061] Sodium alginate, 2%; potassium alginate, 2%; styrene-butadiene rubber, 2%; conductive carbon black, 9%; silicon carbon negative electrode active material, 85%. Among them, the number average molecular weight of sodium alginate and potassium alginate is about 1 million, and the weight ratio of sodium alginate to styrene-butadiene rubber is 2:1.

[0062] The lithium-ion battery prepared by using the above-mentioned negative electrode material was charged and discharged at a rate of 0.5C at 25°C, and the capacity retention rate was 90.6% after 200 cycles.

Embodiment 3

[0064] In the present embodiment, the percentage by weight of each component of the negative electrode material is (in terms of dry material weight):

[0065] Sodium alginate, 1.5%; styrene-butadiene rubber, 1.5%; conductive carbon black, 2%; silicon carbon negative electrode active material, 95%. Among them, the number average molecular weight of sodium alginate is about 50,000, and the weight ratio of sodium alginate to styrene-butadiene rubber is 1:1.

[0066] The lithium-ion battery prepared by using the above-mentioned negative electrode material was charged and discharged at a rate of 0.5C at 25°C, and the capacity retention rate was 91.3% after 200 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com