Aqueous dual-component polyurethane paint system

A technology of two-component coatings and water-based dispersions, which can be used in fiber processing, textiles and papermaking, etc., and can solve the problems that have been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

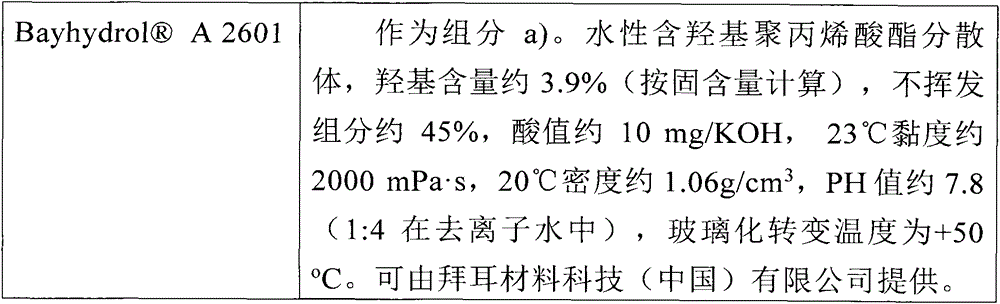

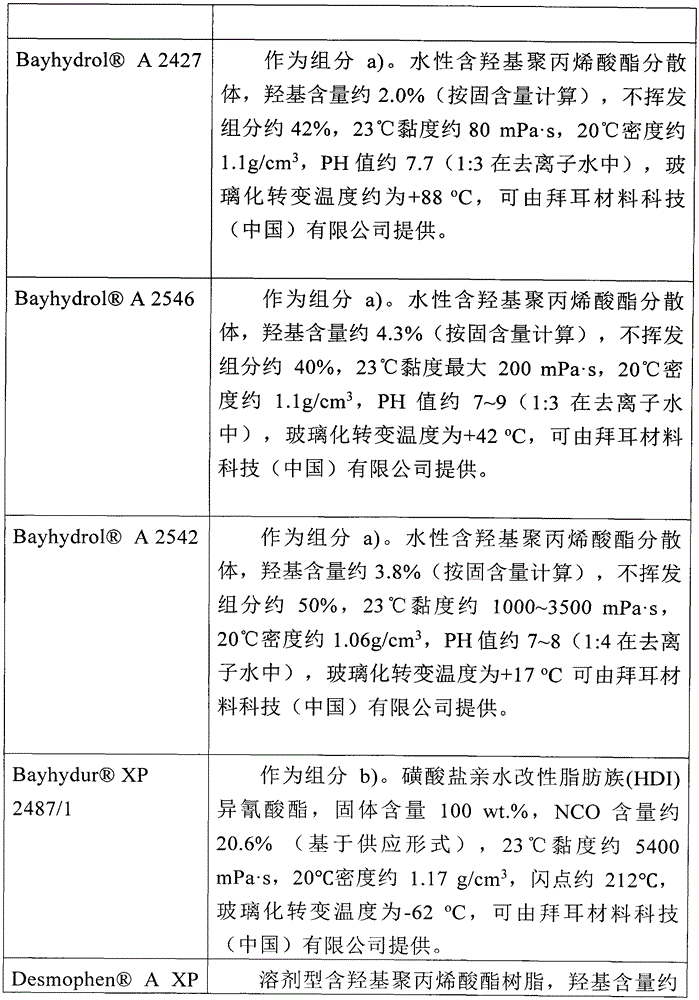

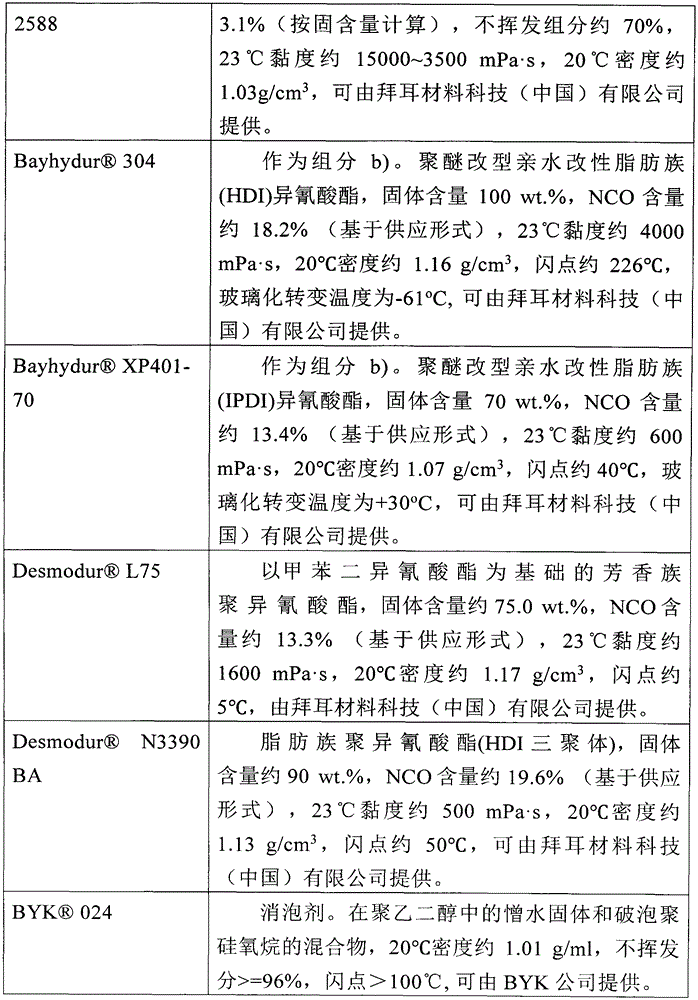

[0050] Raw Materials and Reagents

[0051]

[0052]

[0053]

[0054]

[0055] The coating test items involved in the present invention include anti-liquid paraffin items and drying performance test items. The substrates, pretreatments, and detection and sample preparation methods used are listed in Table 1.

[0056] Table 1 Selection and pretreatment of substrates

[0057]

[0058]

[0059] Coating test samples are prepared, preferably but not limited to, by wire bar coating, and cured in an oven at 60°C for 24 hours. According to actual needs, the wet film thickness is set at 6-120 μm.

Embodiment 1

[0071] Preparation of Component A

[0072] Put 47.00g in the blender container A2601, under medium-low speed (about 1000-1200rpm) stirring, slowly add 11.00g deionized water, 42.00g After A2546, increase the stirring speed to 2500rpm, and keep the stirring speed for 20 minutes to complete the preparation of component A.

[0073] Use a 400-mesh filter to filter the above finished products. The finished products should be properly stored in airtight containers and stored for at least 24 hours before use.

[0074] Preparation of Component B

[0075] Component B is 2487 / 1, use MPA to dilute with curing agent / MPA=3 / 1.

[0076] Use and sample preparation

[0077] Accurately weigh component A and component B according to the mass ratio of 100.00 / 25.00, mix by hand stirring, and stir for 5 minutes to ensure that component A and component B are fully mixed and even, ready to use.

[0078] On the substrate, the composition is coated with a wire bar and cured in an oven at 60°C ...

Embodiment 2

[0082] Preparation of Component A

[0083] Put 42.00g in the blender container A2601, under medium-low speed (about 1000-1200rpm) stirring, slowly add 11.00g deionized water, 47.00g A2542 then increase the stirring speed to 2500rpm, and keep the stirring speed for 20 minutes to complete the preparation of component A.

[0084] Use a 400-mesh filter to filter the above finished products. The finished products should be properly stored in airtight containers and stored for at least 24 hours before use.

[0085] Preparation of Component B

[0086] Component B is 2487 / 1, use MPA to dilute with curing agent / MPA=3 / 1.

[0087] Use and sample preparation

[0088] Accurately weigh component A and component B according to the mass ratio of 100.00 / 28.00, mix by hand stirring, and stir for 5 minutes to ensure that component A and component B are fully mixed evenly before use.

[0089] On the substrate, the composition is coated with a wire bar and cured in an oven at 60°C for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com