A high toughness enamel coating resistant to high temperature hot water corrosion

A high-toughness, high-temperature-resistant technology, applied in the field of enamel coating, can solve problems affecting the service life of the enamel liner, cracks on the enamel body, and poor toughness of the enamel layer, so as to overcome porcelain cracks, high service temperature, and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

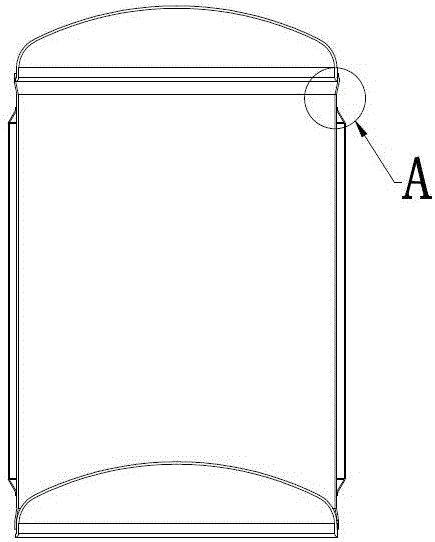

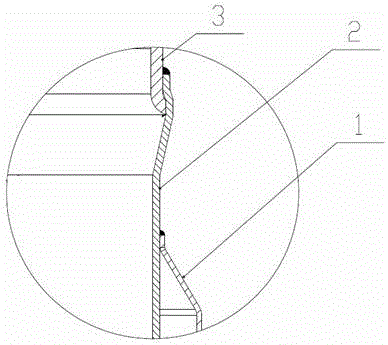

Image

Examples

Embodiment 1

[0036] A high-toughness enamel coating resistant to high-temperature hot water corrosion includes: a porcelain layer base material and abrasives,

[0037] The mass ratio of the porcelain base material is as follows:

[0038] SiO 2 50

[0039] al 2 o 3 1.0

[0040] ZrO 2 5

[0041] TiO 2 2

[0042] B 2 o 3 10

[0043] Li 2 O 3

[0044] Na 2 O 15

[0045] CaF 2 2

[0046] Na 2 SiF 6 2

[0047] CoO 1.5

[0048] NiO 0.3

[0049] MnO 0.3;

[0050] The mass portion proportioning of described ground addition thing is as follows:

[0051] Glaze (cullet) 100

[0052] Quartz sand 25

[0053] Zirconia fiber 5

[0054] Y 2 o 3 0.3

[0055] Magnesium carbonate 0.5

[0056] Borax pentahydrate 0.4

[0059] The enamel coating and metal liner of the above ratio are used to fire the enamel liner for water heaters. The firing temperature is 860°C. After the 180° bending test, the porcelain will no...

Embodiment 2

[0061] A high-toughness enamel coating resistant to high-temperature hot water corrosion includes: a porcelain layer base material and abrasives,

[0062] The mass ratio of the porcelain base material is as follows:

[0063] SiO 2 52

[0064] ZrO 2 8

[0065] TiO 2 5

[0066] B2 o 3 12

[0067] Li 2 O 2

[0068] Na 2 O 14

[0069] CaF 2 2

[0070] Na 2 SiF 6 3

[0071] CoO 1

[0072] NiO 0.2

[0073] MnO 0.4;

[0074] The mass portion proportioning of described ground addition thing is as follows:

[0075] Glaze 100

[0076] Quartz sand 18

[0077] Zirconia fiber 10

[0078] Y 2 o 3 0.5

[0079] Magnesium carbonate 0.8

[0080] Borax pentahydrate 0.3

[0082] Sodium nitrite 0.4.

[0083] The enamel coating and metal liner of the above ratio are used to fire the enamel liner for water heaters. The firing temperature is 860°C. After the 180° bending test, the porcelain will not fall off and has high toughness. Af...

Embodiment 3

[0085] A high-toughness enamel coating resistant to high-temperature hot water corrosion includes: a porcelain layer base material and abrasives,

[0086] The mass ratio of the porcelain base material is as follows:

[0087] SiO 2 50

[0088] Al 2 o 3 0.8

[0089] ZrO 2 3

[0090] TiO 2 4

[0091] B 2 o 3 10

[0092] Li 2 O 3

[0093] Na 2 O 16

[0094] CaF 2 4

[0095] Na 2 SiF 6 1

[0096] CoO 1.5

[0097] NiO 0.4

[0098] MnO 0.5;

[0099] The mass portion proportioning of described ground addition thing is as follows:

[0100] Glaze 100

[0101] Quartz sand 20

[0102] Zirconia fiber 8

[0103] Y 2 o 3 0.3

[0105] Borax pentahydrate 0.5

[0106] Sodium aluminate 0.3

[0107] Sodium nitrite 0.4.

[0108] The enamel coating and metal liner of the above ratio are used to fire the enamel liner for water heaters. The firing temperature is 860°C. After the 180° bending test, the porcelain will not fall off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com