High-purity hydrogen production equipment for crystalline silicon preparation and high-purity hydrogen production process for crystalline silicon preparation

A technology for production equipment and crystalline silicon, applied in the fields of hydrogen, silicon compounds, inorganic chemistry, etc., can solve the problems of difficult to guarantee the stability of crystalline silicon preparation, waste of methanol raw materials, inability to modularize, etc., to avoid hydrogen leakage and low consumption of raw materials , the effect of low overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

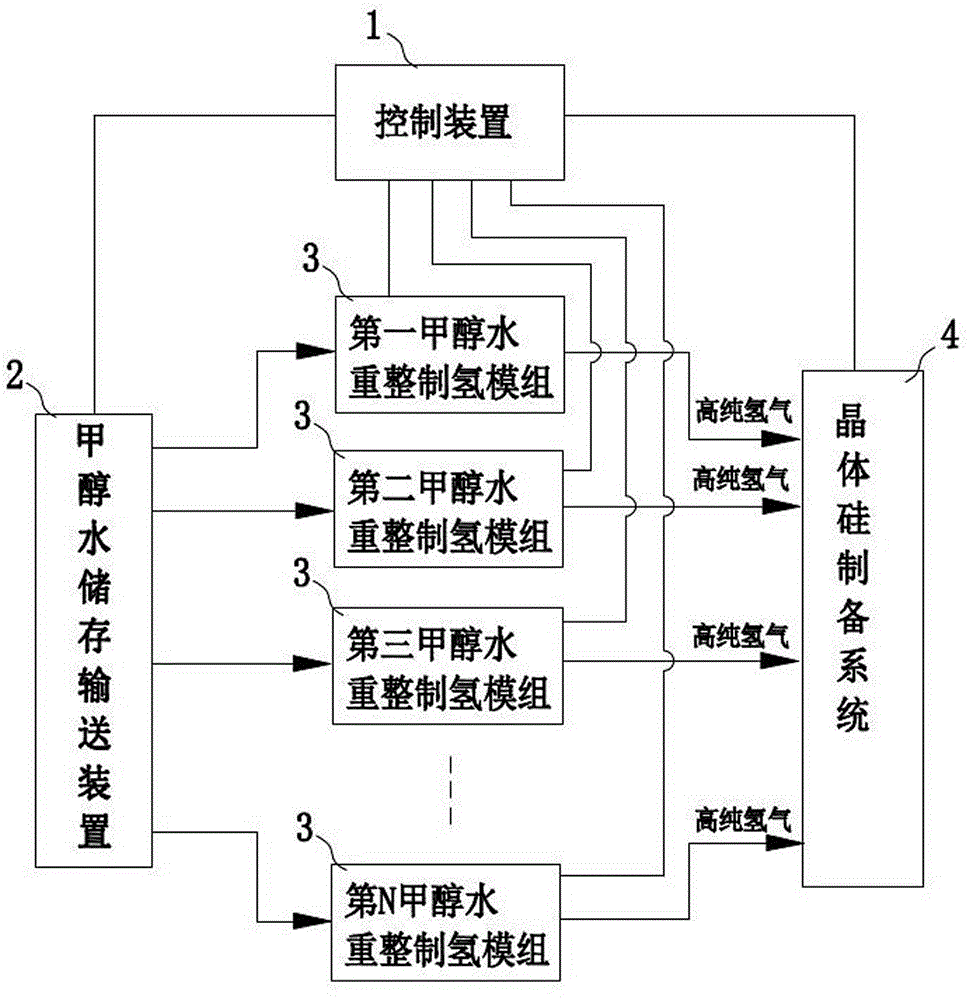

[0038] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] Such as Figure 9 As shown, it is a block diagram of the overall structure of the crystalline silicon preparation system. The silicon trichloride or silicon tetrachloride raw material is refined and purified in the refining tower 6 to obtain silicon trichloride or silicon tetrachloride with a purity greater than 99.995%. raw material; then silicon trichloride or silicon tetrachloride raw material is sent to vaporizer 7 for vaporization; then, the vaporized silicon trichloride or silicon tetrachloride raw material and high-purity hydrogen with a purity of 99.9999% to 99.99999 are according to 1: The molar ratio of 2 to 1:10 is mixed in the mixer 8 to obtain the mixed gas raw material; then, the mixed gas raw material is sent to the reduction furnace 9, and the reduction furnace 9 is controlled by adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com