Manufacturing method for pressing powder into welded ring

A manufacturing method and powder technology, applied in the field of heterosexual self-wetting welding ring manufacturing, can solve the problems of large workload, low welding efficiency, low welding ring forming rate, etc., and achieve the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the manufacturer's conditions, and the unspecified implementation conditions are usually conventional experimental conditions.

[0037] 1. Manufacture of brass welding ring

[0038] See structure figure 1 and figure 2 , the inner wall of the brass welding ring 1 is connected with an annular protrusion 2, which is arranged in steps with the inner wall of the brass welding ring.

[0039] The manufacturing method of described brass welding ring comprises the steps:

[0040] a) Sieving

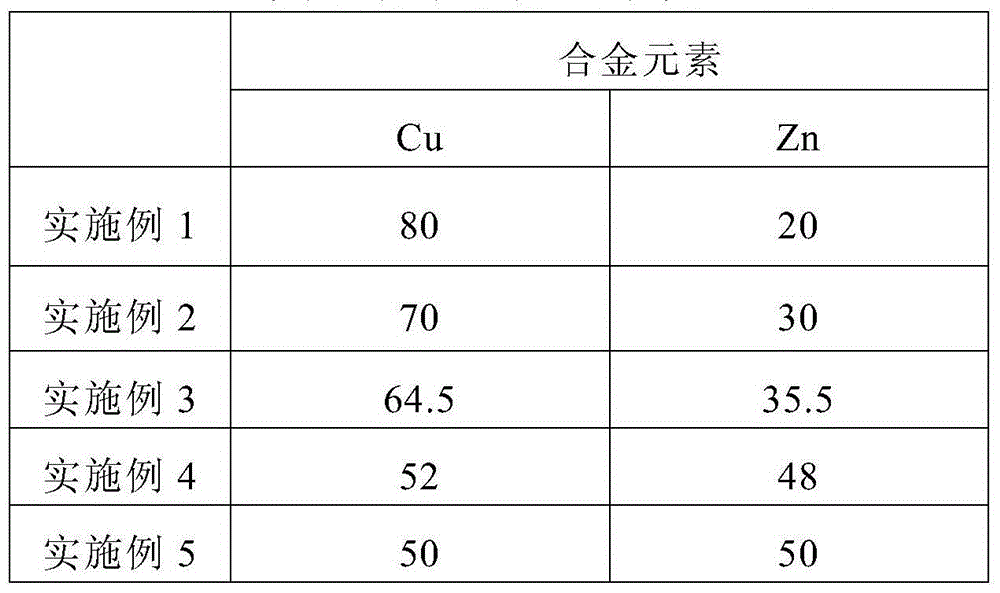

[0041] Brass alloy powder (Cu x Zn 100-x , the specific composition is shown in Table 1) Pour into a vibrating sieve for classification, and the undersize is for use; pour the flux powder into a vibrating sieve for classification, and the undersize is for use; po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com