Driving device of steel ladle sliding nozzle mechanism

A technology of sliding nozzle and driving device, which is applied to casting melt containers, metal processing equipment, casting equipment, etc., can solve problems such as cost increase, steel leakage, affecting the service life of refractory materials, etc., so as to improve service life and avoid swinging up and down. , the effect of preventing steel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

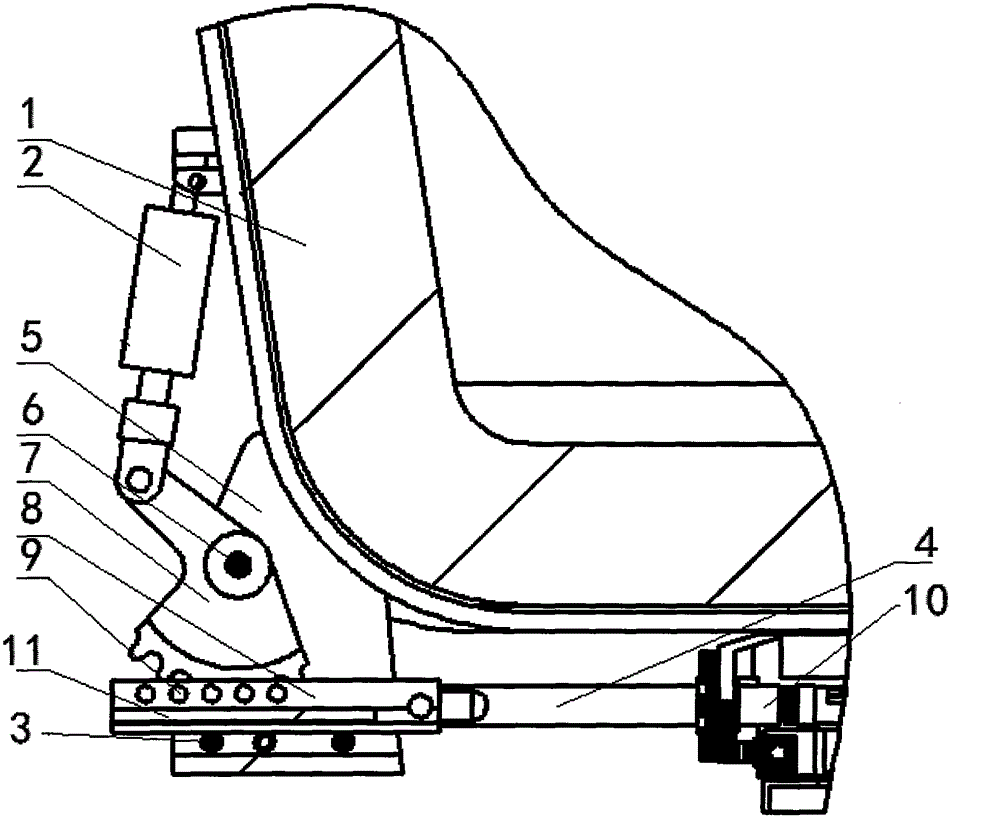

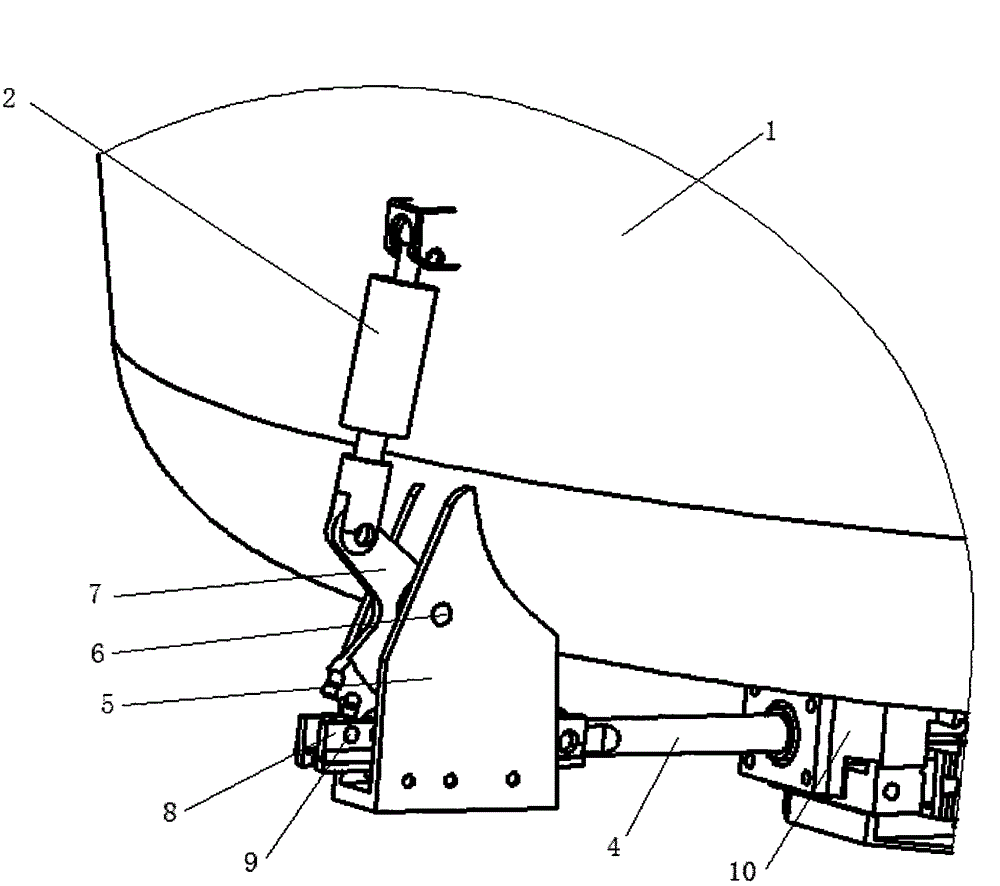

[0011] Such as figure 1 , 2 As shown, a driving device of a ladle sliding nozzle mechanism of the present invention includes a bracket 5 fixed on the ladle 1, the bracket 5 is a U-shaped structure, and the bottom of the bracket 5 is provided with a plurality of rotating shafts 3, the A shaft sleeve is provided between the rotating shaft 3 and the support 5; a sprocket 7 is hinged through a pin 6 in the middle of the support 5, and a hydraulic cylinder 2 is connected to the sprocket 7, and the hydraulic cylinder 2 is rotatably installed on the ladle 1 on;

[0012] A chain groove 8 is provided above the rotating shaft 3, a chain 11 is provided below the chain groove 8, and a plurality of roller shafts 9 are arranged on the top of the chain groove 8, and rollers are arranged on the roller shaft 9. The sprocket 7 passes through the roller and cooperates with the chain 11;

[0013] One end of the chain groove 8 is fixed to the connecting rod 4 , and the free end of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com