Automatic spraying system and control method for crusher cavity and belt conveyor

A belt conveyor and automatic spraying technology, applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the deviation of the current value detected by the current transformer, the error of the measured short-circuit current, and the insufficient working accuracy of the system, etc. problems, to achieve the effect of preventing slippage, less water consumption, and quicker cost recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

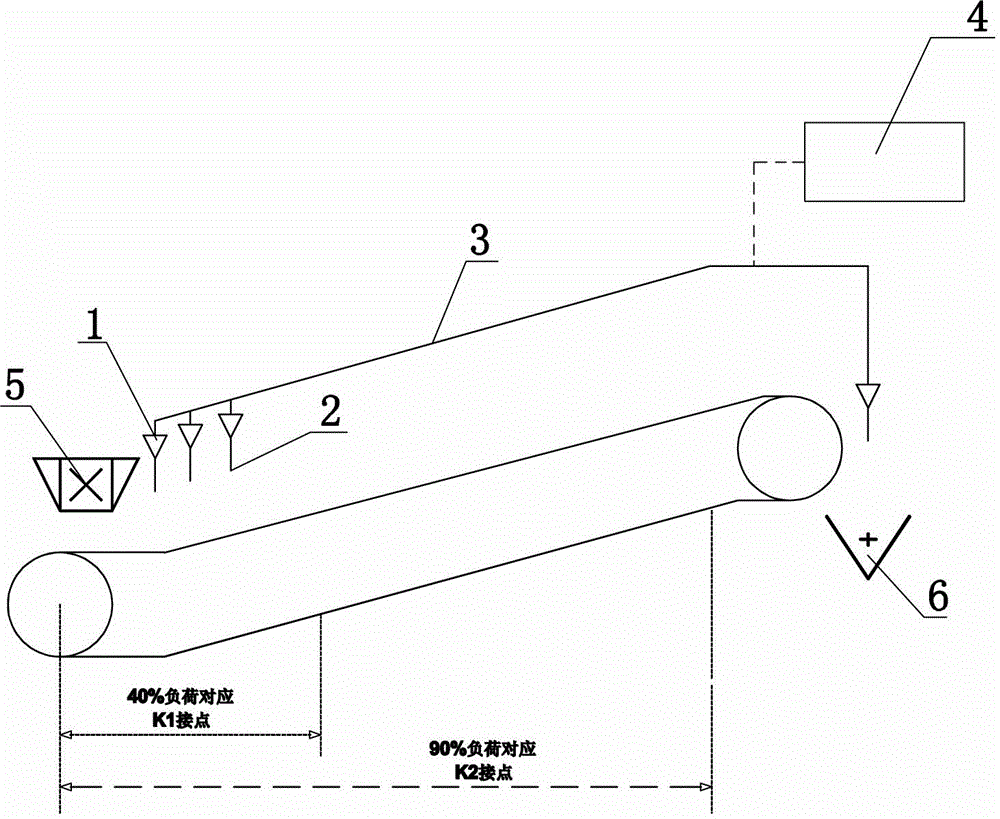

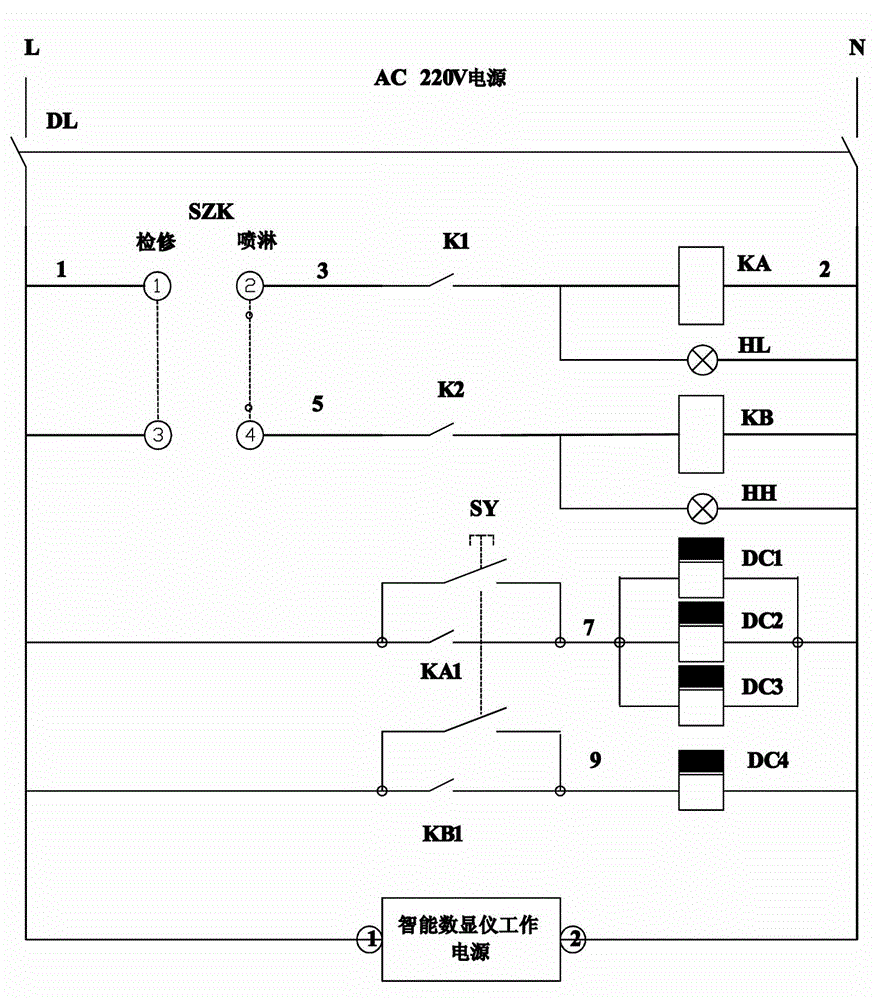

[0022] like figure 1 As shown, the automatic spraying system of the crusher cavity and the belt conveyor of the present invention includes a spraying water supply pipeline 3, and the spray head 2 located on the spraying water supply pipeline 3 is characterized in that it is compatible with the spraying water supply pipeline 3. The water supply pipeline 3 is also connected with an automatic control system 4. The sprinkler head 2 is provided with a spray solenoid valve 1. The automatic control system 4 includes a frequency converter, an intelligent digital display and connecting wires connecting various components.

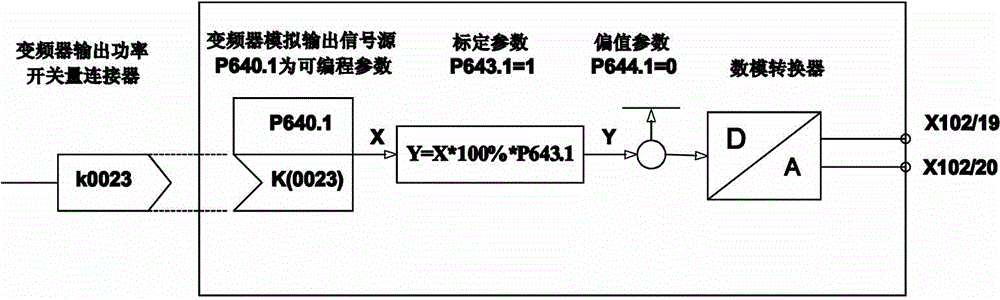

[0023] The frequency converter includes a frequency converter I / O board.

[0024] The intelligent digital display includes an integrated instrument chip and double-row four-digit LEDs.

[0025] In the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com