Two-dimension cosine waveform surface light tripping structure and solar film cell based on same

A technology of solar cells and light-trapping structures, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of disordered structures, area limitations, and inability to prepare nanostructures, and achieve good angle sensitivity, large forming area, The effect of the strong coupling feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

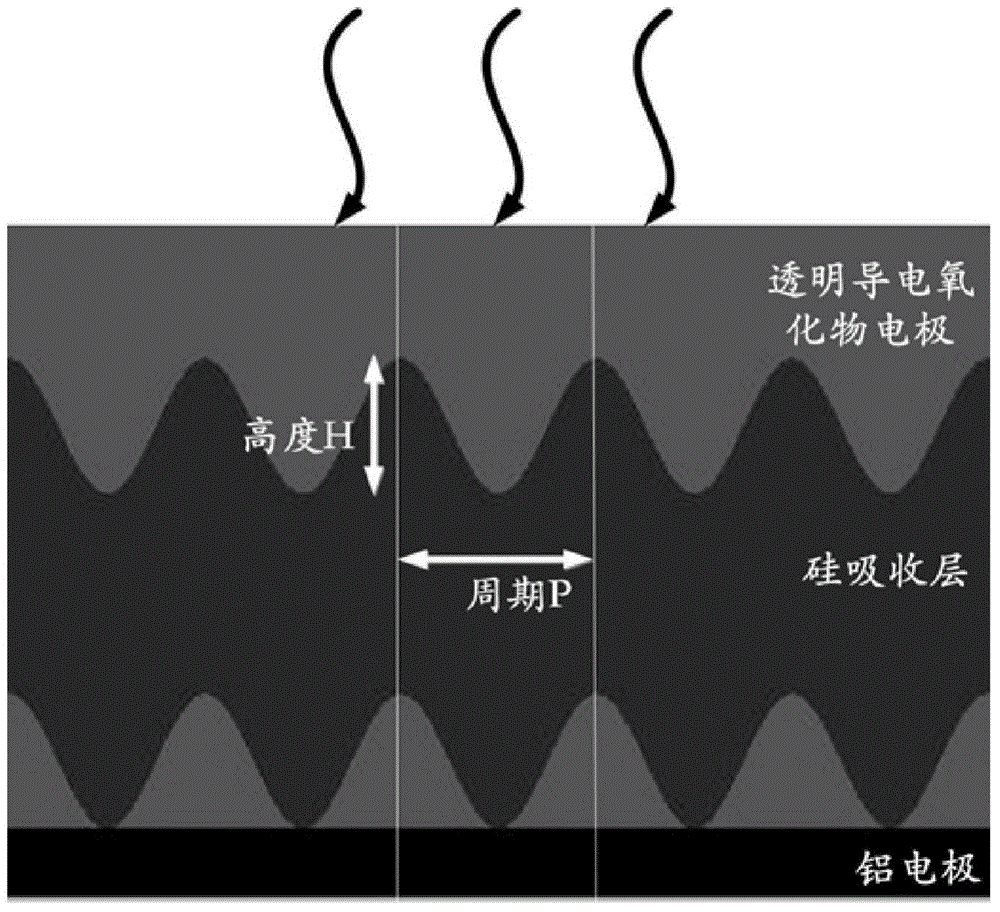

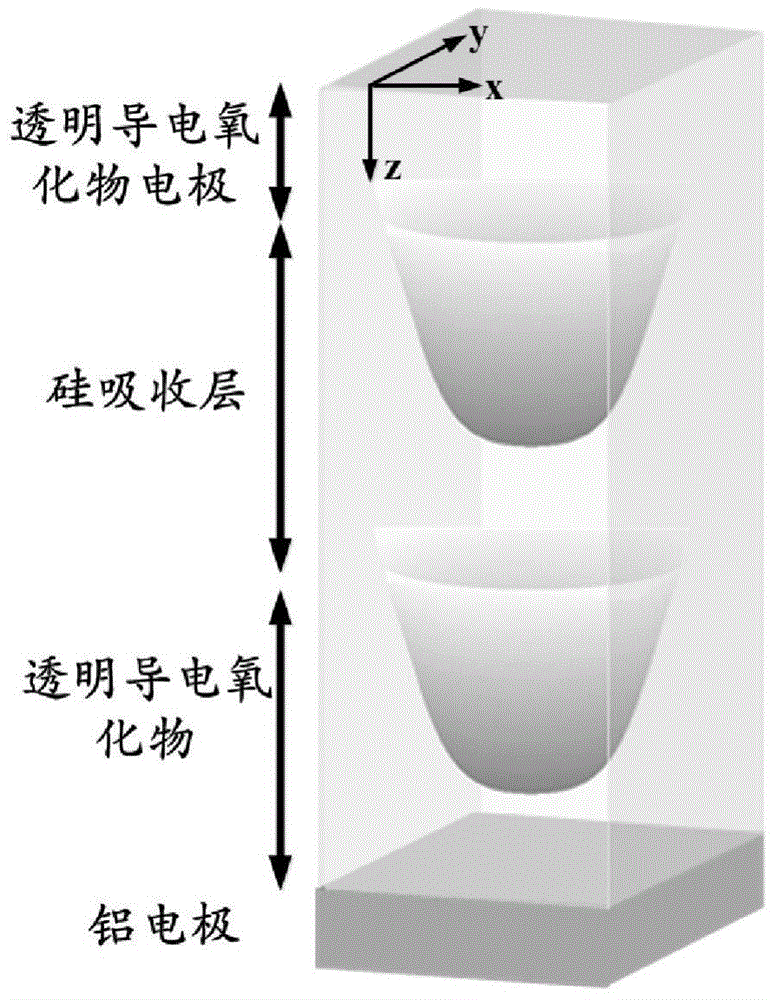

[0022] The preparation method of the silicon-based thin-film solar cell in the present invention comprises the following steps: depositing a transparent conductive oxide on the base of the metal electrode, making a cosine waveform light-trapping structure by interference lithography, and then sequentially depositing and doping to make a silicon absorber layer PN junction, and then use interference lithography to make a cosine waveform light-trapping structure, and finally deposit a transparent conductive oxide.

[0023] The absorption enhancement effect of the periodic two-dimensional cosine wave surface light-trapping structure can be determined according to the short-circuit current density J sc To evaluate, its expression is as follows:

[0024] J sc = q hc ∫ λ · A ( λ ) · I ...

Embodiment 1

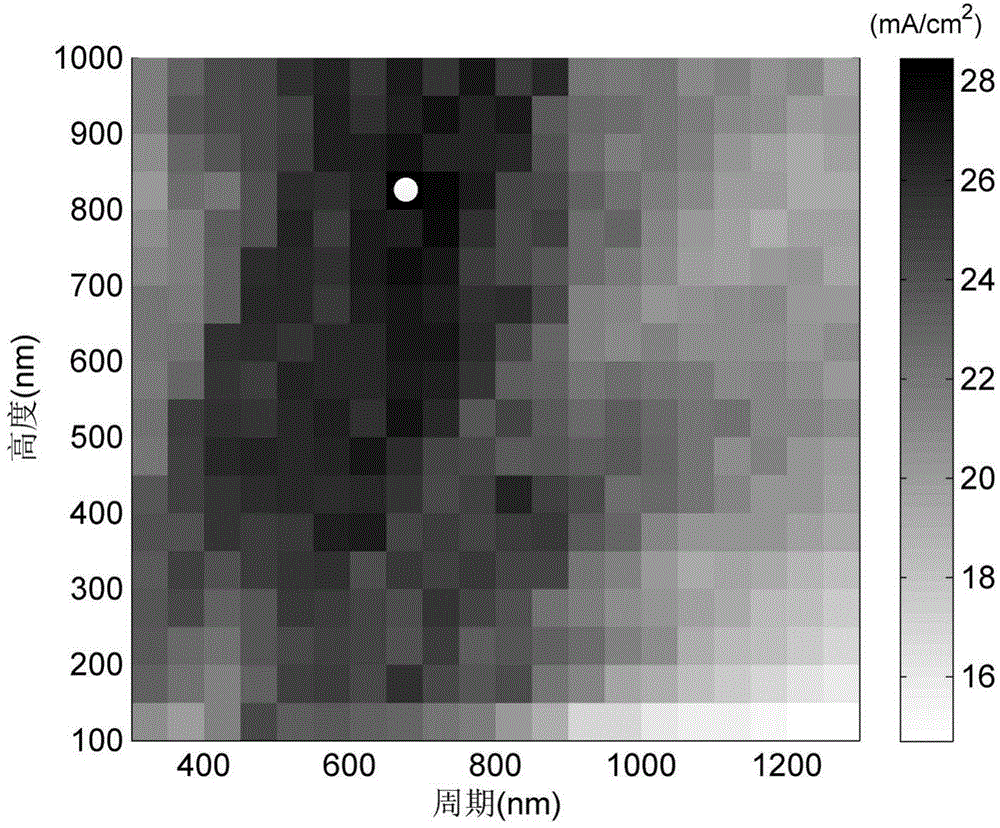

[0027] The battery structure we give (see figure 1 with figure 2 ) of the silicon absorption layer thickness is 1000nm, because the effects of two-dimensional light-trapping structures with different periods and heights on absorption enhancement are different, therefore, by evaluating the period P variation range of 300nm to 1300nm and the height H variation range of 100nm at normal incidence Short-circuit current density J corresponding to different light-trapping structures to 1000nm sc (P,H) to optimize the period and height of the periodic two-dimensional light-trapping structure.

[0028] Through this optimization method, the two-dimensional cosine wave surface light trapping structure is optimized, such as image 3 As shown, the period and height of the best two-dimensional cosine wave surface light-trapping structure are 650nm and 800nm respectively (see image 3 The white dot in ), the corresponding short-circuit current density is 28.46mA / cm 2 . Similarly, an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com