Tower type biomass continuous carbonization furnace

A technology of biomass and carbonization furnaces, applied in fixed carbonization furnaces, biofuels, coke ovens, etc., can solve the problems of unsatisfactory yield, inability to realize continuous production, high energy consumption, etc., and achieve sufficient carbonization and cooling, structure Simple, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

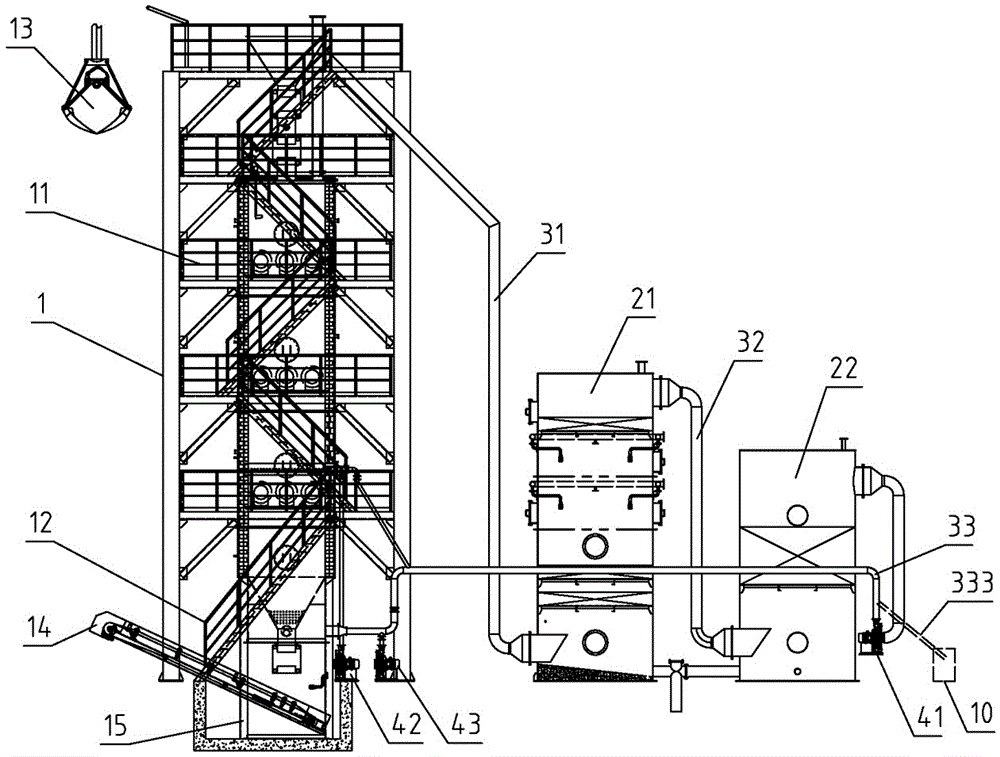

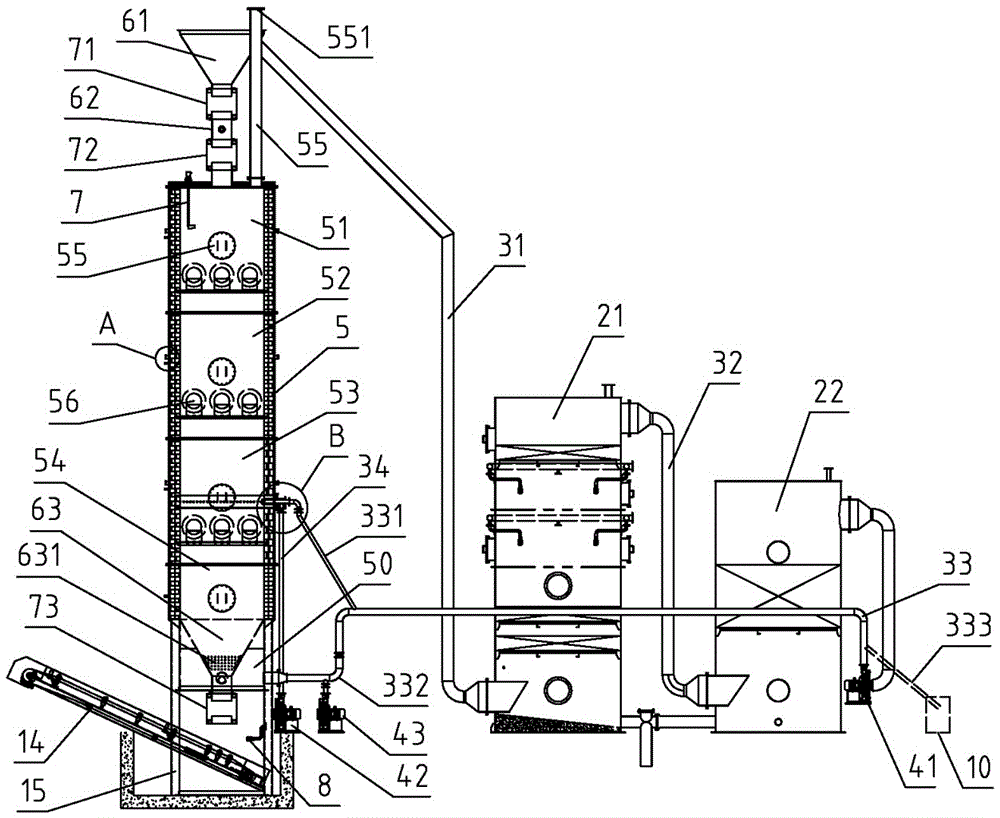

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] like figure 1 As shown, the tower-type biomass continuous carbonization furnace of the present invention includes: a mounting base 15 and a furnace body 5 with an inner cavity, and the furnace body 5 is installed on the mounting base 15. In this embodiment, the inner diameter of the furnace body 5 The height ratio with the furnace body 5 is 1:10-1:15. In the actual use process, the support frame 1 supporting the furnace body 5 is also arranged on the periphery of the furnace body 5, and several platforms 11 are arranged at intervals from bottom to top on the support frame 1. 11 of the ladder 12.

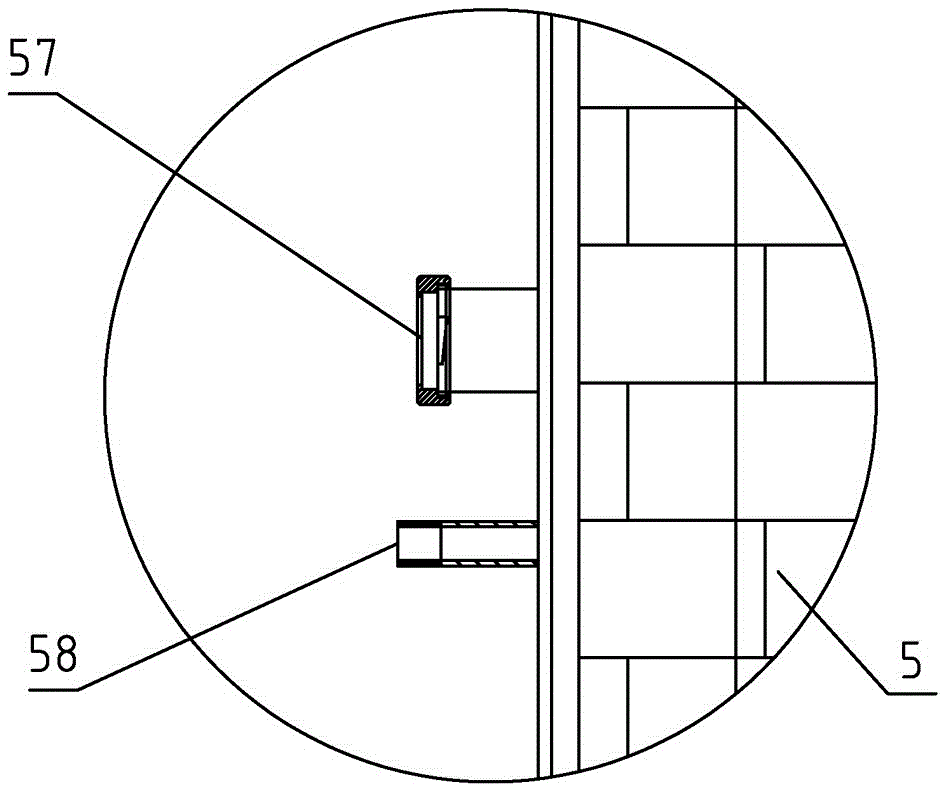

[0025] like figure 2 and Figure 5 As shown, four chambers of drying chamber 51, carbonization chamber 52, high temperature chamber 53 and cooling chamber 54 are arranged sequentially from top to botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com