Method for preparing alginate liquid crystalline phases

The technology of alginate and liquid crystal phase is applied in the field of polymer liquid crystal, which can solve the problems of difficulty in forming liquid crystal phase, rigidity of molecular chain length, etc., and achieve the effects of obvious bright field, low cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

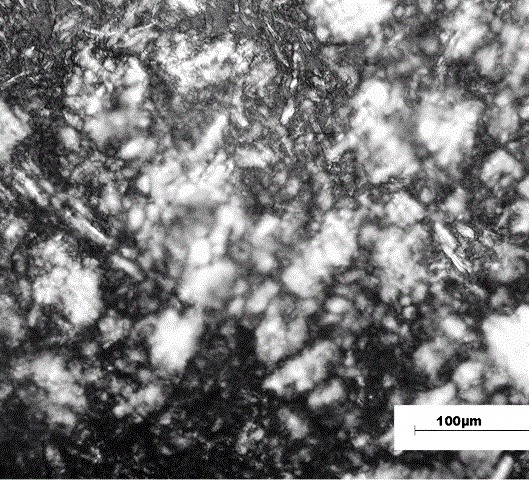

Image

Examples

Embodiment 1

[0024] Weigh 11.7g of sodium chloride into 100ml of distilled water, stir until it is fully dissolved, and obtain a 2mol / L sodium chloride salt solution; then add 2g of sodium alginate powder to the sodium chloride solution while stirring, and then add the above solution Stir at room temperature for 20 hours, then put it in a 70°C water bath and stir for 5 minutes; the prepared sodium alginate / sodium chloride mixed solution was centrifuged for 3 hours, it was observed that the solution was divided into upper and lower phases, separated by a separatory funnel Out the lower liquid crystal phase.

Embodiment 2

[0026] Weigh 25.2g of sodium bicarbonate into 100ml of distilled water, stir until it is fully dissolved to obtain a 3mol / L sodium hydrogen nitrate solution; then add 0.2g of sodium alginate powder to the sodium bicarbonate solution while stirring, and then add the above The solution was stirred at room temperature for 5 minutes and then placed in a 50°C water bath for 5 hours; the prepared sodium alginate / sodium hydrogen nitrate mixed solution was centrifuged at rest, and the solution was observed to be divided into upper and lower phases. The funnel separates the lower liquid crystal phase.

Embodiment 3

[0028] Weigh 72g of sodium bisulfate into 100ml of distilled water, stir until fully dissolved to obtain a 6mol / L sodium bisulfate solution; then add 20g of sodium alginate powder to the sodium bisulfate solution while stirring, and then bring the above solution to room temperature After stirring for 12 hours, put it in a 60℃ water bath and stir for 2 hours; After 4 hours of centrifugation, the prepared sodium alginate / sodium bisulfate mixed solution will be divided into upper and lower phases, which are separated by a separatory funnel. Lower liquid crystal phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com