Anti-fog treatment method for plastic substrate and anti-fog plastic prepared therefrom

A processing method and technology for plastic substrates, which are applied in polyether coatings, chitin coatings, hyaluronic acid coatings, etc., can solve problems such as poor durability of anti-fog coatings, and achieve good water resistance and water vapor resistance. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

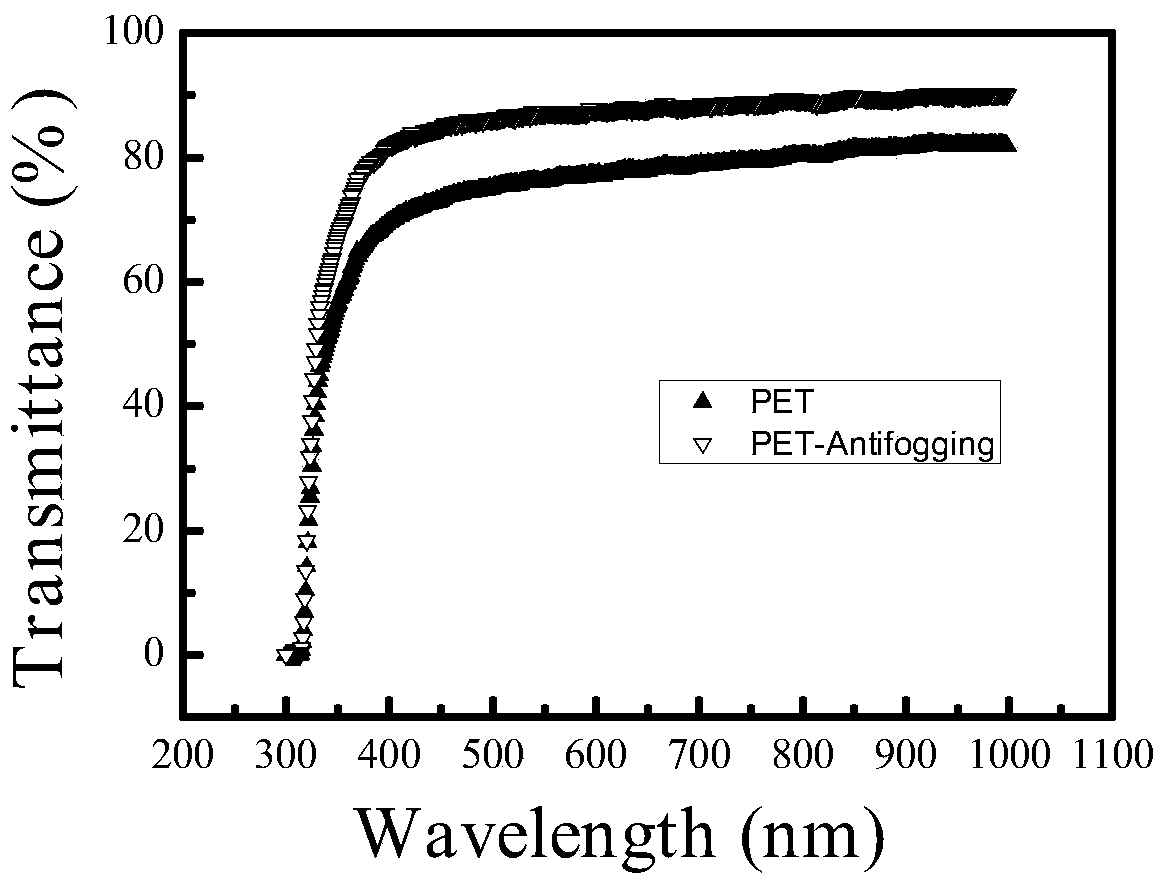

Image

Examples

Embodiment 1

[0034] The washed and dried polyethylene sheet was pretreated for 60s with a low-temperature plasma surface treatment machine at a voltage of 50V. Dissolve and disperse 0.05% polyacrylic acid in 99.95% secondary aqueous solution, ultrasonically disperse for 10 minutes, and then apply dip coating on the surface of polyethylene sheet treated with low-temperature plasma surface, and dry to obtain a thickness of 34nm The modification layer. The polyethylene sheet containing the modified layer was treated with superthermal hydrogen, the voltage of the superthermal hydrogen treatment was 100V, the degree of vacuum was 0.05Pa, and the treatment time was 120s to obtain the final durable anti-fog plastic sheet.

Embodiment 2

[0036] The washed and dried polyethylene sheet was pretreated for 55s with a low-temperature plasma surface treatment machine at a voltage of 75V. Dissolve and disperse 0.1% chitosan quaternary ammonium salt in 99.9% secondary aqueous solution, ultrasonically disperse for 10 minutes, and then apply spin coating on the surface of polyethylene sheet treated with low-temperature plasma surface, dry, A modified layer with a thickness of 18 nm was obtained. The polyethylene sheet containing the modified layer was treated with superthermal hydrogen, the voltage of superthermal hydrogen treatment was 150V, the degree of vacuum was 0.1Pa, and the treatment time was 90s to obtain the final durable anti-fog plastic sheet.

Embodiment 3

[0038] After cleaning and drying, the polypropylene sheet was pretreated with a low-temperature plasma surface treatment machine at a voltage of 75V for 50s. Dissolve and disperse 0.2% polyethylene glycol and 0.2% nano-silicon dioxide (particle size: 7nm) in 99.6% secondary water, ultrasonically disperse for 20 minutes, prepare a modified solution, and then apply it on the surface by spraying. The surface of the polypropylene sheet treated with low-temperature plasma was dried to obtain a modified layer with a thickness of 123 nm. The polypropylene sheet containing the modified layer was treated with superthermal hydrogen, the voltage of the superthermal hydrogen treatment was 200V, the degree of vacuum was 0.15Pa, and the treatment time was 60s to obtain the final durable anti-fog plastic sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com