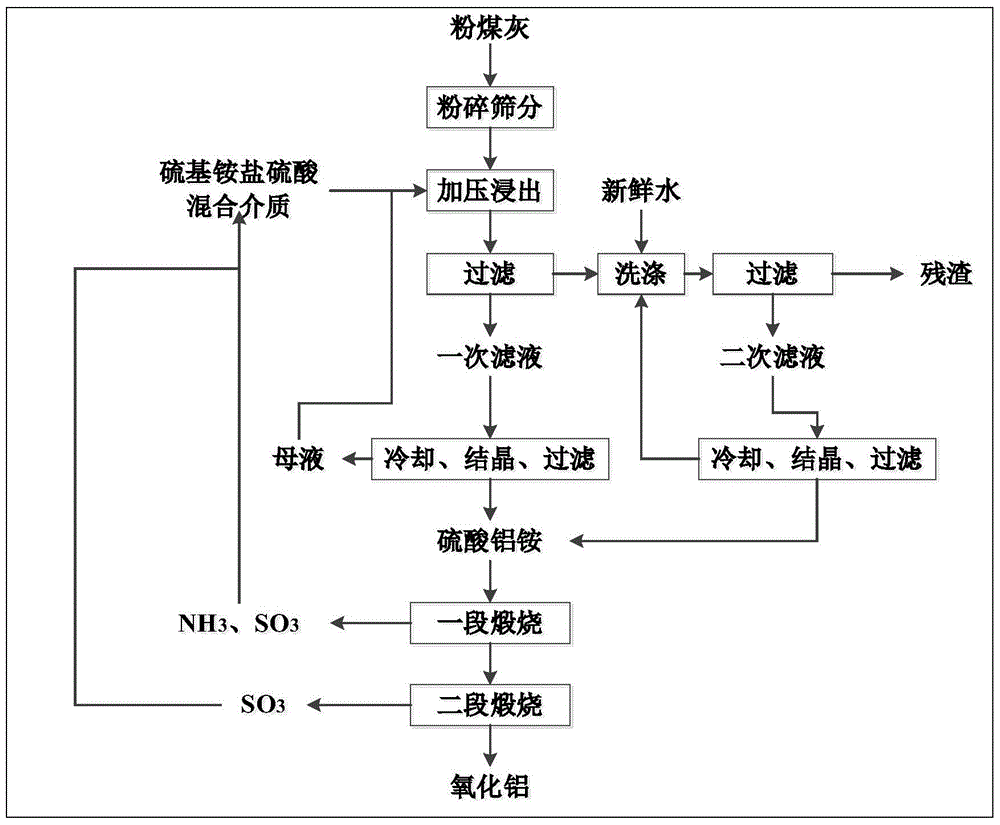

A method for extracting alumina from fly ash with a sulfammonium salt mixed medium system

A technology of mixed media and sulfur-based ammonium salt, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of large consumption of sulfur-based ammonium salt, difficult separation of impurities, difficulty in ammonia recovery, etc., to avoid high-temperature calcination and high energy consumption process, improving extraction efficiency, and the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

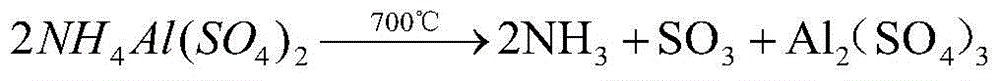

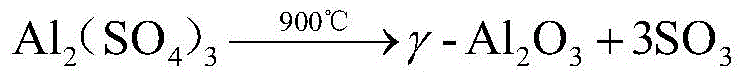

[0056] The fly ash of a coal-fired power plant selected in this embodiment has an alumina content of 47.58% and a silicon oxide content of 44.30%. The specific process is as follows:

[0057] 1) Mechanically pulverize and sieve the fly ash to a particle size smaller than 100 mesh;

[0058] 2) Prepare NH 4 + The concentration is 5mol / L, H + A mixed medium system of ammonium sulfate and sulfuric acid with a concentration of 15mol / L;

[0059] 3) According to the liquid-solid ratio of 10 / 3 (ml / g), add 33.3g of the fly ash obtained in step 1) and 100ml of the mixed medium solution obtained in step 2) into the closed reactor with stirring , carry out alumina leaching reaction;

[0060] 4) Heat the closed system in step 3) to 220°C, the pressure is about 0.25MPa, and react for 6h;

[0061] 5) Cool the system after the reaction in step 4) to 90°C, and filter to obtain the primary filtrate and primary filter residue;

[0062] 6) Cool the primary filtrate obtained in step 5) to 10...

Embodiment 2

[0071] The fly ash of a coal-fired power plant selected in this embodiment has an alumina content of 25.58% and a silicon oxide content of 67.12%. The specific process is as follows:

[0072] 1) Mechanically pulverize and sieve the fly ash to a particle size smaller than 200 mesh;

[0073] 2) Prepare NH 4 + The concentration is 20mol / L, H + A mixed medium system of ammonium sulfate and sulfuric acid with a concentration of 20mol / L;

[0074] 3) Add 50.0g of the fly ash obtained in step 1) and 100ml of the mixed medium solution obtained in step 2) into a closed reactor with stirring at a liquid-solid ratio of 10 / 2 (ml / g) , carry out alumina leaching reaction;

[0075] 4) Heat the closed system in step 3) to 240°C, the pressure is about 0.4MPa, and react for 0.5h;

[0076] 5) Cool the system after the reaction in step 4) to 95°C, and filter to obtain the primary filtrate and primary filter residue;

[0077] 6) Cool the primary filtrate obtained in step 5) to 15°C, a large a...

Embodiment 3

[0086] The fly ash of a coal-fired power plant selected in this embodiment has an alumina content of 32.29% and a silicon oxide content of 60.06%. The specific process is as follows:

[0087] 1) Mechanically pulverize and sieve the fly ash to a particle size smaller than 300 mesh;

[0088] 2) Prepare NH 4 + The concentration is 15mol / L, H + A mixed medium system of ammonium sulfate and sulfuric acid with a concentration of 25mol / L;

[0089] 3) According to the liquid-solid ratio of 10 / 4 (ml / g), add 25.0g of the fly ash obtained in step 1) and 100ml of the mixed medium solution obtained in step 2) into the closed reactor with stirring , carry out alumina leaching reaction;

[0090] 4) Heat the closed system in step 3) to 120°C, the pressure is about 0.2MPa, and react for 6h;

[0091] 5) Cool the system after the reaction in step 4) to 75°C, and filter to obtain the primary filtrate and primary filter residue;

[0092] 6) Cool the primary filtrate obtained in step 5) to 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com