Overhead working truck leveling system based on boom limit and control method thereof

A technology for aerial work vehicles and booms, which is applied in the directions of fluid pressure actuation system components, lifting devices, fluid pressure actuation devices, etc. Circuit flow supply and other problems, to achieve the effect of solving insufficient leveling flow supply, small leveling hysteresis, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

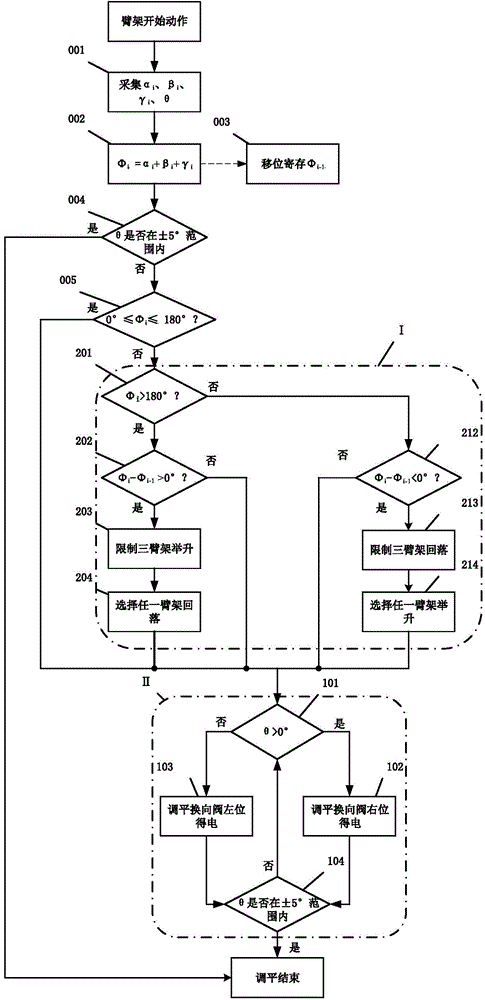

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

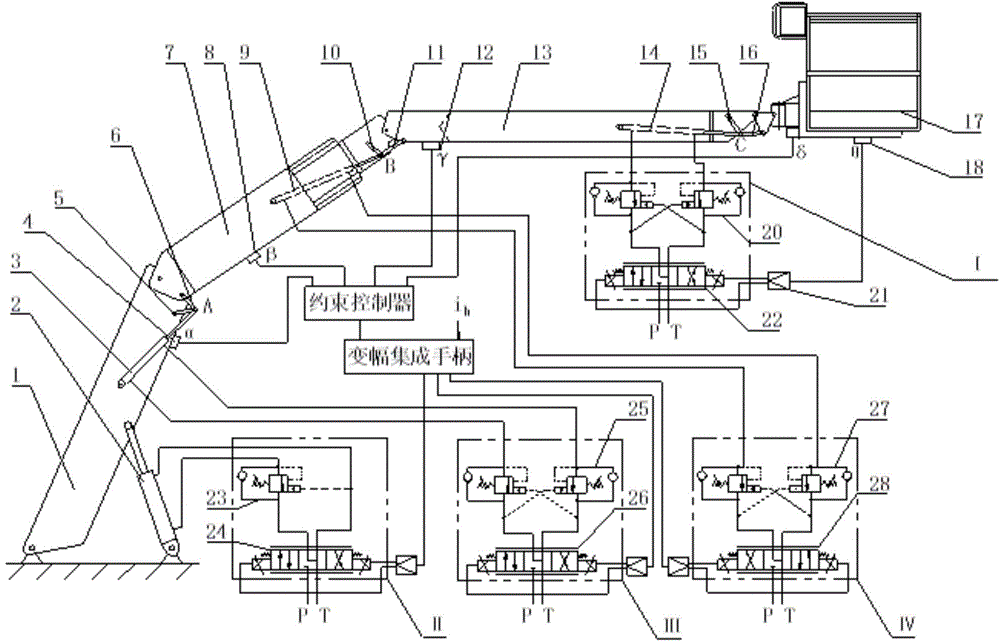

[0039] see figure 1 and figure 2 , a leveling system for aerial work vehicles based on boom constraints, including a lower arm 1, an upper arm 7, a flying arm 13 and a workbench 17, the lower arm 1 is hinged to the ground through the lower arm luffing system, and the lower arm 1 The support arm 1 is hinged with the upper support arm 7 through the upper support arm luffing system, the upper support arm 7 is hinged with the fly arm 13 through the fly arm luffing system, and the workbench 17 is hinged with the fly arm 13 through the workbench leveling system;

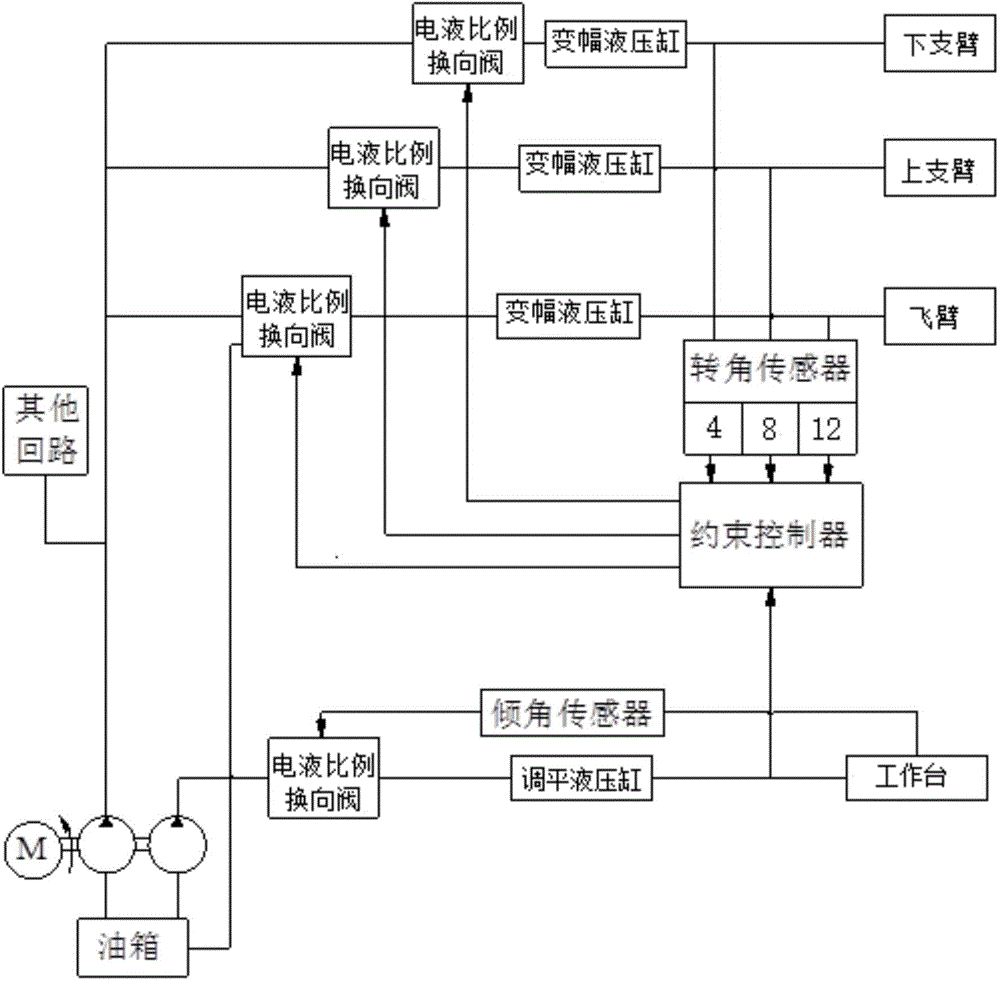

[0040] The lower arm 1 is provided with a lower arm angle sensor 4, the upper arm 7 is provided with an upper arm angle sensor 8, the fly arm 13 is provided with a fly arm angle sensor 12, and the workbench 17 is provided with an inclination sensor 18. The lower arm angle sensor 4, the upper arm angle sensor 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com