Semi-trailer traction saddle

A semi-trailer, saddle technology, which is applied in the direction of tractor-trailer combination, motor vehicle, transportation and packaging, etc., can solve the damage of the saddle mounting plate, the unfavorable use of the saddle, and the cracking of the saddle mounting plate of the saddle support body. and other problems to achieve the effect of reducing stress and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

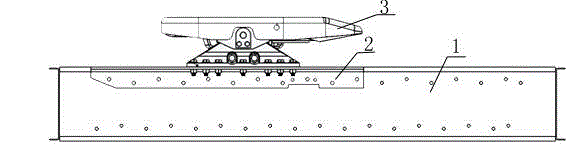

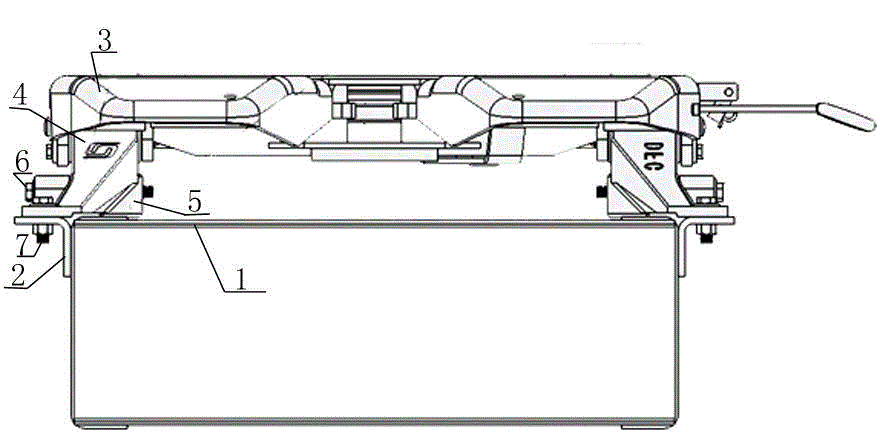

[0015] The present invention as figure 1 , 2 , 3, 4 shown.

[0016] The semi-trailer vehicle traction saddle includes a vehicle frame 1, and the vehicle frame 1 is symmetrically provided with left and right vehicle frame support beams 2, and the left and right vehicle frame support beams 2 are correspondingly connected with left and right saddles by bolts 1-7 Support 4, left and right saddle supports 4 are connected with saddle 3; The inboard of left and right saddle supports 4 is correspondingly provided with left and right saddle slanting block 5, wherein the bottom surface of left and right saddle slanting block 5 and The plane of the vehicle frame 1 is fitted, the slopes of the left and right saddle slant blocks 5 are respectively attached to the inner slopes of the left and right saddle brackets 4, and the saddle slant blocks 5 are connected to the left and right saddle brackets through the transverse bolt 2 6 4 connections.

[0017] Wherein the saddle support 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com