Ink Supply System Used For Ink-jet Printer, And Ink Pressure Control Method In System

An inkjet printer and ink supply technology, applied in printing and other directions, can solve problems such as complex device structure, and achieve the effects of easy operation, easy control, and reduced maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

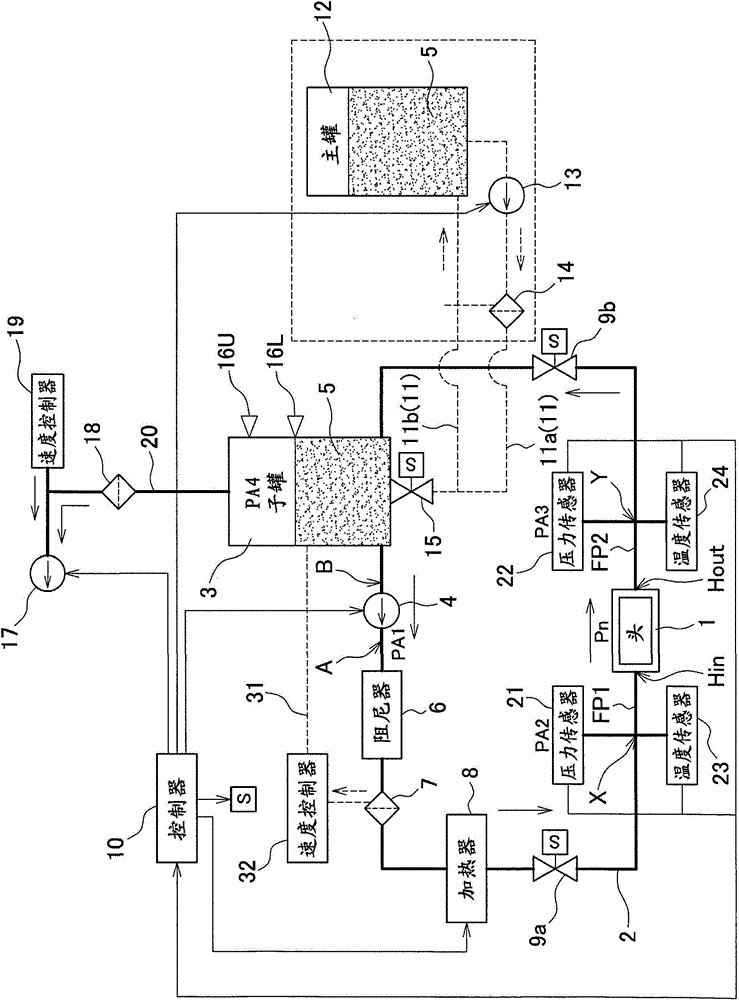

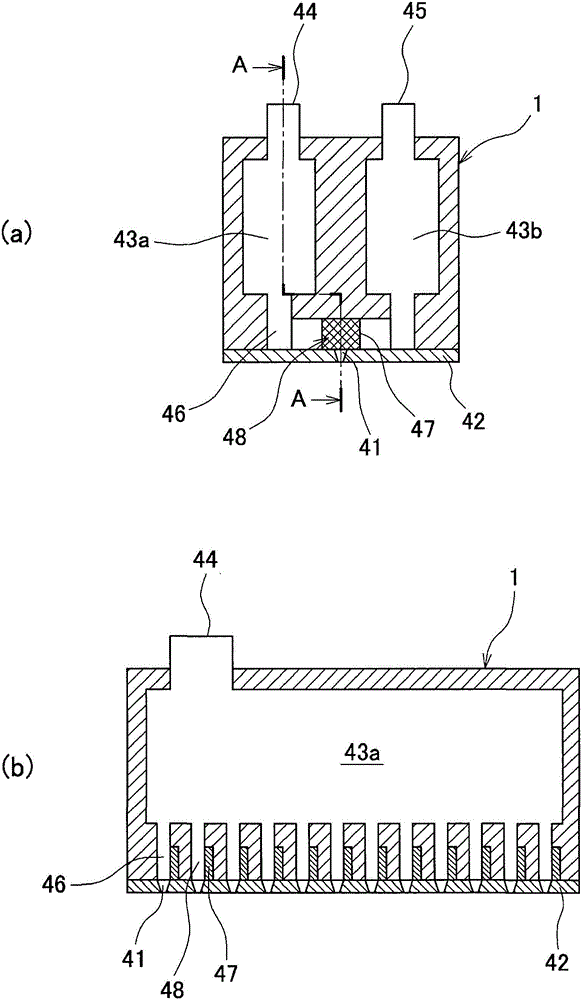

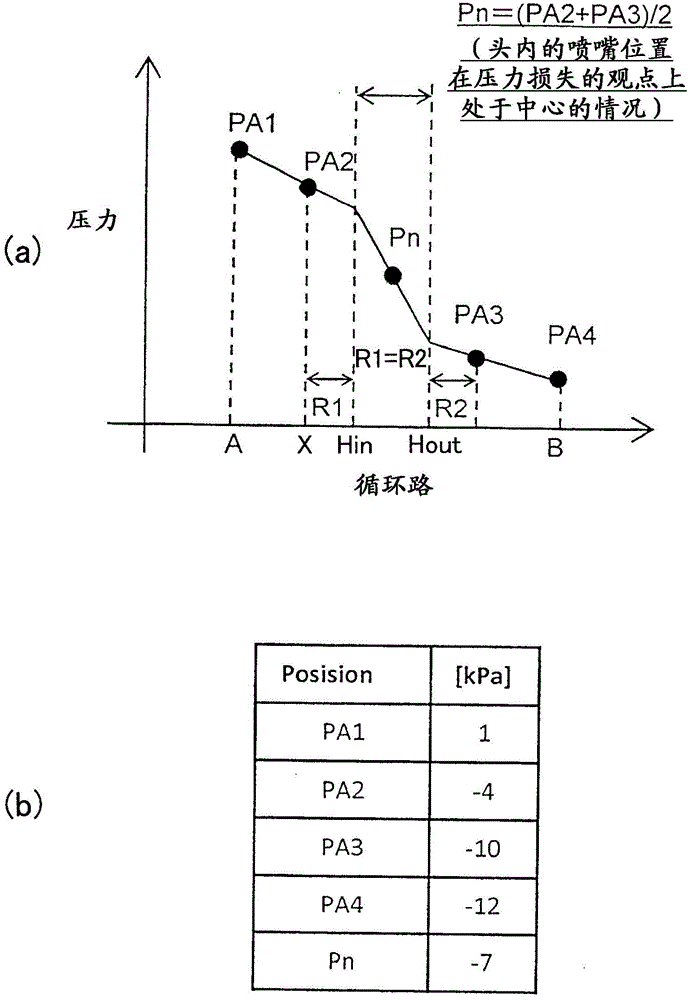

[0021] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is an explanatory diagram showing the outline of an ink supply system for an inkjet printer according to an embodiment of the present invention. The ink supply system of the present invention is a device that circulates and supplies ink to an inkjet head 1 (hereinafter simply referred to as head 1 ) provided with ink discharge nozzles via an ink circulation path 2 . Such as figure 1 As shown, ink 5 is supplied from a sub-tank (ink tank) 3 to the head 1 through a main pump 4 . As the main pump 4, a metering pump such as a gear pump is used. Among them, the type of the main pump 4 such as a tube pump and a diaphragm pump is not particularly limited.

[0022] In the ink circulation path 2, a damper 6, a filter 7, a heater (temperature adjustment unit) 8, and solenoid valves 9a and 9b are provided. The damper 6 is disposed downstream of the main pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com