Hard alloy reaming drill bit

A technology of reaming drill bit and cemented carbide, which is used in striking tools, lightweight impact tools, manufacturing tools, etc., can solve the problems of short service life, poor wear resistance, low hardness, etc., and achieves large cutting area and cutting speed. Faster, higher cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

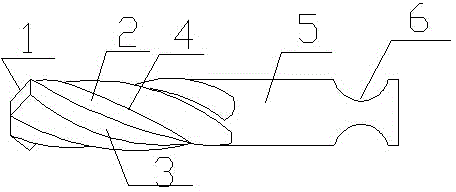

[0016] Reference numerals: 1. Front cutter, 2. Drill body, 3. Cutting groove, 4. S-shaped cutter, 5. Drill shank, 6. Positioning groove

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0018] The structure of the novel electric hammer drill bit of the present invention is as figure 1 As shown, a cemented carbide reaming drill bit is formed by connecting two parts of a drill body 2 and a drill handle 5, and is characterized in that: the drill body 2 is provided with an S-shaped cutter 4 and a front cutter 1; The structure is a cylinder; the drill shank 5 is provided with a positioning groove 6 near the end position. The structure of the drill body 2 is a ∞-shaped body with straight end faces at both ends. The front end of the drill body 2 is provided with a front cutter 1, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com