Novel high-speed hollow drill bit

A hollow drill, high-speed technology, applied in the direction of drill, drill repair, drill accessories, etc., can solve the problems of low processing speed, low drilling strength of drill bit, etc., achieve high cutting strength, avoid sudden breakage, smooth cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

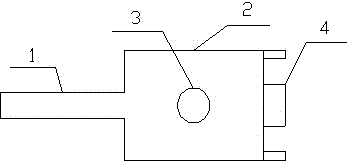

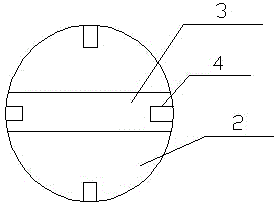

[0016] Reference numerals: 1. Drill handle, 2. Drill body, 3. Ventilation hole, 4. Serrated cutter

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0018] The structure of novel high-speed hollow drill bit of the present invention is as figure 1 As shown, a new type of high-speed hollow drill bit is characterized in that: the drill body is composed of three parts: the drill body 2, the cutting part and the drill handle 1, one end of the drill body 2 is connected with the cutting part, and the drill body 2 is connected with the cutting part The other end of the drill body 2 is connected with the drill shank 1, and the drill body 2 and the drill shank 1 are integrally formed; the structure of the drill shank 1 is a slender cylinder structure, and the length of the slender cylinder shan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com