High-performance integrated absorption tower for dust removal and desulfuration via physical method

A high-performance physical and absorption tower technology, applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problem that the effect of smoke and dust treatment does not meet the national standard, the sulfur content of flue gas does not meet the requirements, and the environment Adverse effects and other problems, to achieve the effect of good dust removal, long contact time, and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

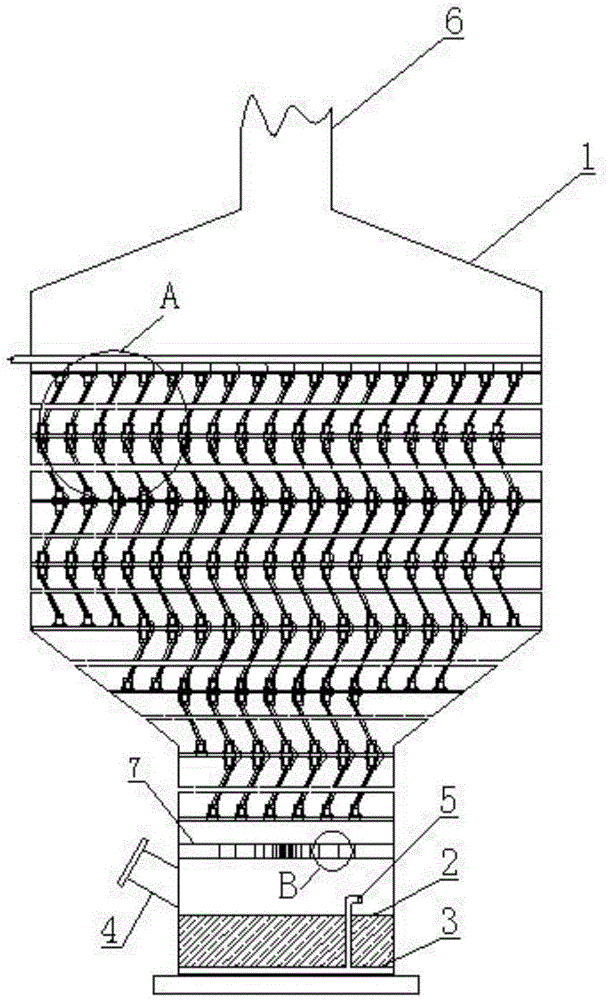

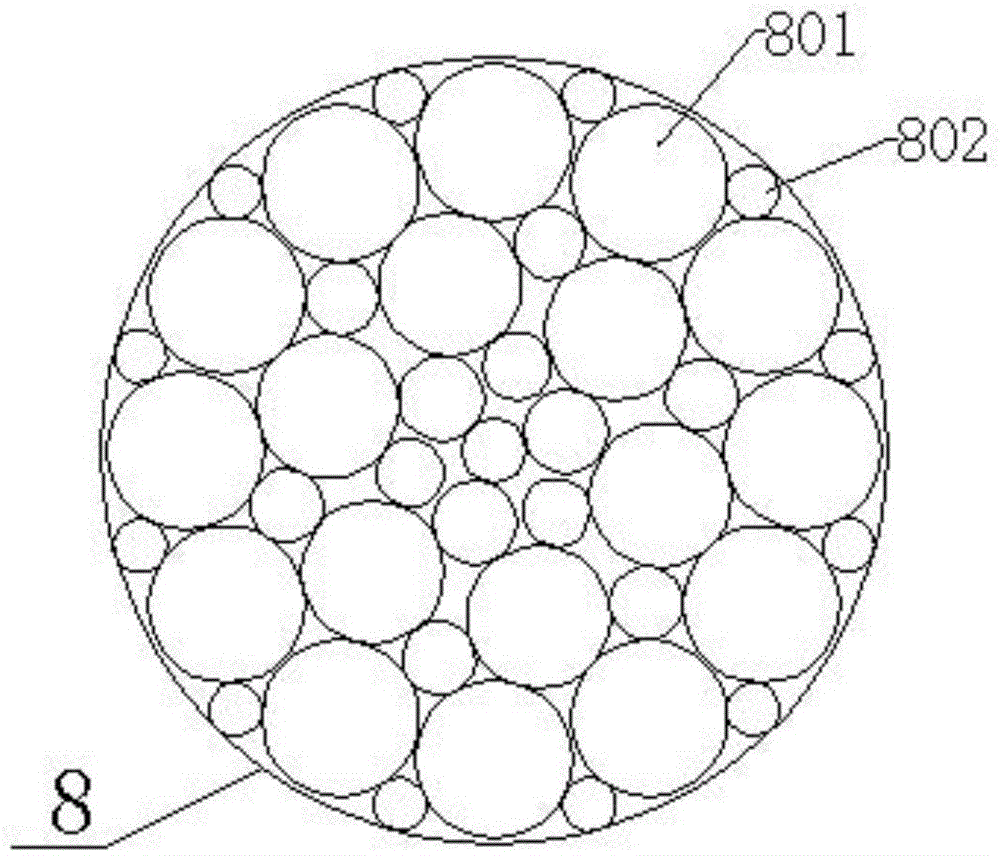

[0027] Such as figure 1 , figure 2 and image 3 As shown, a high-performance physical dust removal and desulfurization integrated absorption tower includes a tower body 1, an alkali solution tank 2 is arranged at the bottom of the tower body 1, an oxidation air distribution pipe 3 is arranged at the bottom of the alkali solution tank 2, and an oxidation air distribution pipe 3 is arranged at the bottom of the tower body 1. A flue gas inlet 4 and an oxidation air inlet 5 connected to the oxidation air distribution pipe 3 are arranged above the lye tank 2, a clean flue gas outlet 6 is arranged on the top of the tower body 1, and a flue gas outlet 6 is arranged above the flue gas inlet 4 in the tower body 1. Air equalizer7. Such as Figure 4 , Figure 5 As shown, the flue gas flow equalizer 7 includes a flow equalizer plate body 8, and a plurality of annularly distributed flow equalization main holes 801 are arranged on the flow equalizer plate body 8 from the inside to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com