Device used to monitor bolt fracture or looseness

A bolt and monitoring plate technology is applied in the field of devices for monitoring bolt breakage or loosening, which can solve the problems that the device cannot play a monitoring role, cannot monitor the bolt structure, is prone to corrosion or oxidation, etc., and achieves simple structure, wide monitoring range, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

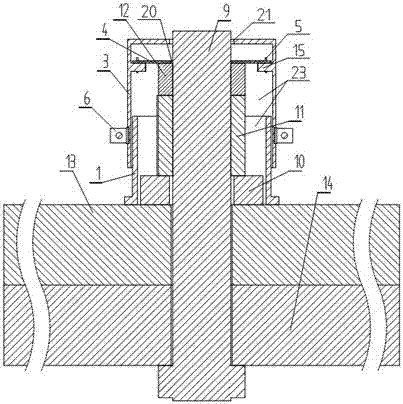

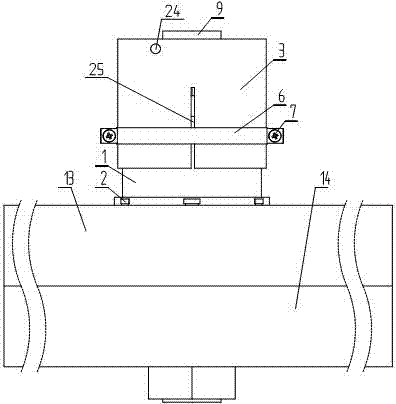

[0030] Such as figure 1 The shown device for monitoring bolt breakage or loosening includes a cylindrical housing, the lower part of which is made of insulating material, and a hollow space with a lower end opening and a diameter greater than that of the washer 10 is provided in the housing. cavity 23, and the tail of the bolt 9 and the washer 10, fastening nut 11 and locknut 12 arranged on the bolt 9 are all located in the cavity 23, and also includes a monitoring circuit, which includes a power supply 26, a switch assembly, The resistor 27 connected to the positive pole of the power supply 26, the output terminal 29 connected to the resistor 27, the connection point of the resistor 27 and the output terminal 29 is connected to one end of the switch assembly, and the other end of the switch assembly is grounded. The switch assembly includes a monitoring plate 4 arranged on the upper end surface of the locknut 12, a trigger structure fixed in the middle or upper part of the ca...

Embodiment 2

[0035] Such as Figure 6 to Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that a normally open switch is formed between the monitoring board 4 and the trigger structure, and the locknut 12 moves upward with the monitoring board 4 to make the switch assembly turn on. The trigger structure is a ring plate 17 fixed on the top wall of the cavity 23 and parallel to the monitoring board 4 .

[0036] Specifically, the ring plate 17 is conductive and connected to the resistor 27 , the monitoring board 4 is conductive and grounded, and the center of the ring plate 17 is provided with a third through hole 22 through which the bolt 9 can pass. The ring plate 17 is fixed on the top wall of the cavity 23 by four second screws 18; the second screws 18 are provided with second nuts 19, and the distance between the monitoring plate 4 and the ring plate 17 is 0.5-2mm after installation. In particular, the diameters of the first through hole 20 and the third thr...

Embodiment 3

[0041] Such as Figure 10 As shown, the difference between the present embodiment and the first embodiment is that the bolt 9 passes through the fastened member 13 and is installed on the base 14 by threading, and the tail of the bolt 9 is located in the base 14 at this time. The bolt head 33 is located in the cavity 23 , and the monitoring board 4 is arranged on the bolt head 33 . When the bolt 9 becomes loose or broken, the bolt head 33 will move upward with the monitoring board 4, and the U-shaped wire 5 will be pulled off, the ground terminal of the monitoring circuit will be disconnected, and the external output level signal state will be will change, so that the bolt 9 is known to be faulty. The triggering structure and monitoring circuit in this embodiment can also be changed to the triggering structure and monitoring circuit described in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com