Measuring and adjusting process-considered tolerance design method of precise machine tool

A technology of precision machine tools and design methods, applied in computing, special data processing applications, instruments, etc., and can solve problems such as excess precision and insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] Aiming at the problems of relying on the experience of engineers in the tolerance design process of existing machine tools, and the problems of insufficient precision and excess precision, the present invention invents a precision machine tool tolerance design method considering the measurement and adjustment process, which includes a method for determining the optimal adjustment amount of the assembly adjustment process And the accuracy distribution method of the machine tool.

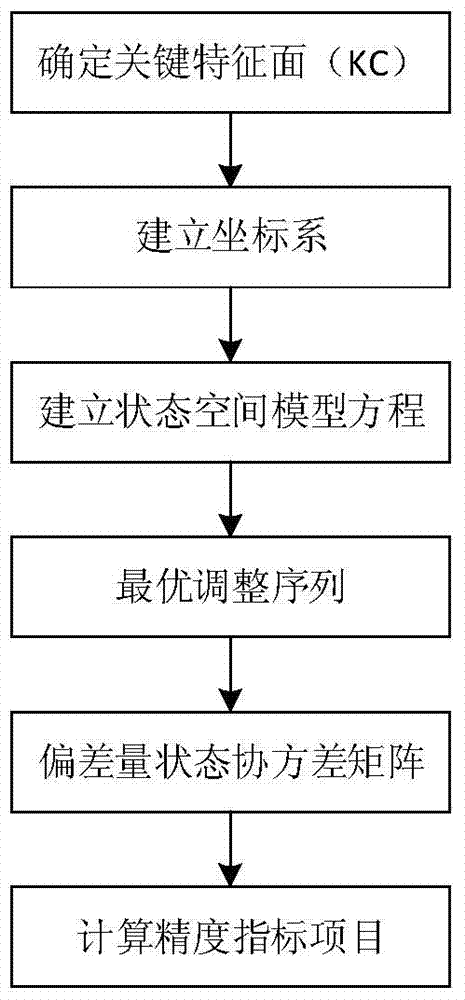

[0047] The process flow of the precision machine tool tolerance design method considering the measurement and adjustment process provided by the present invention is as follows: figure 1 As shown, the specific steps are:

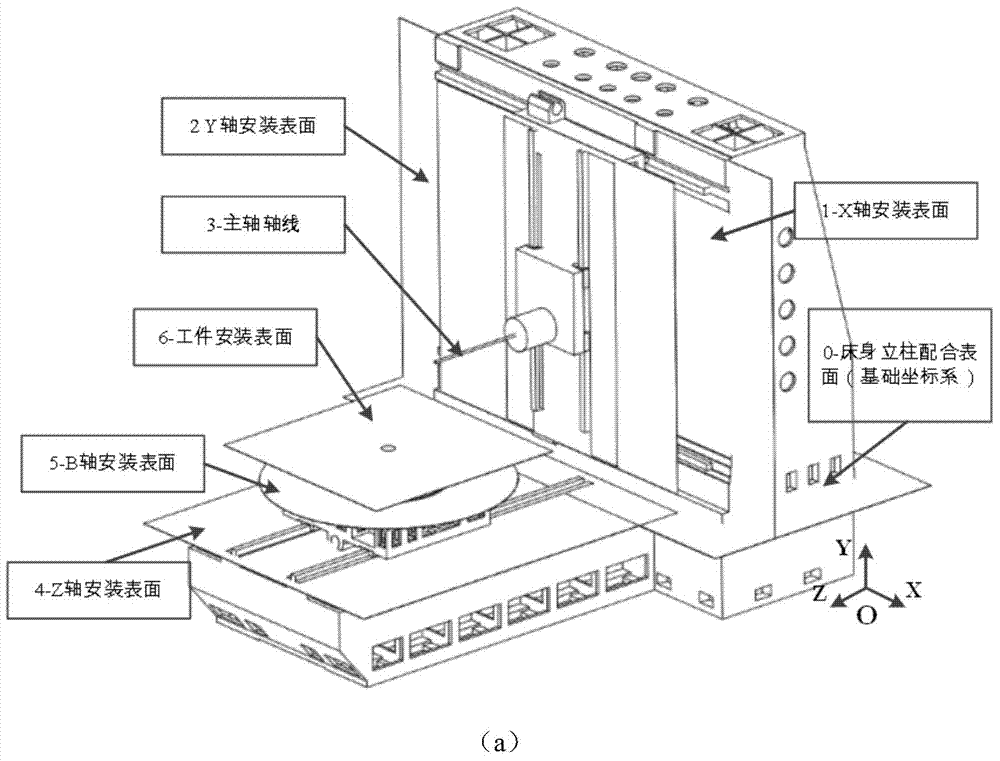

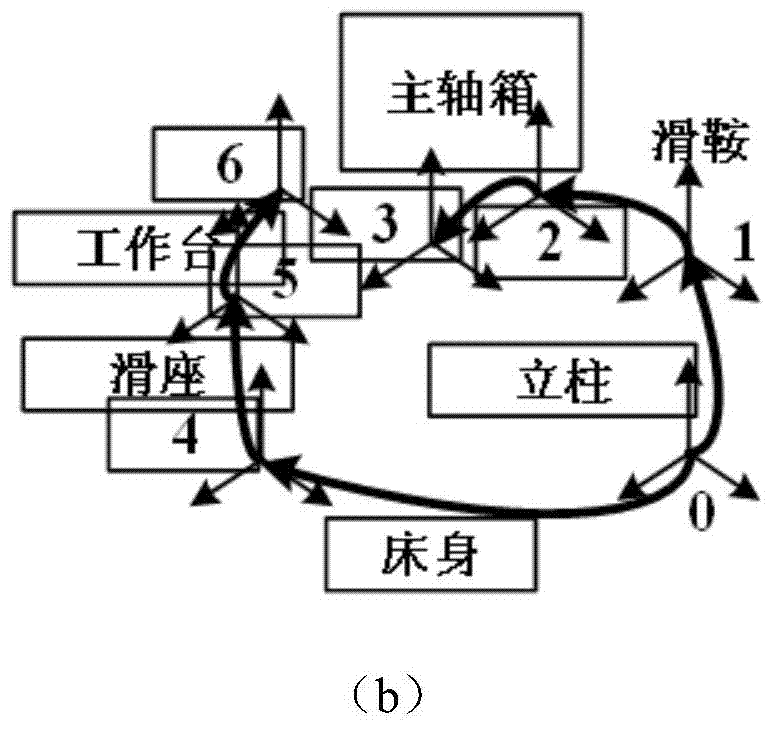

[0048] 1) Select and determine the key feature surface (KC): first simplify the machine tool to the basic large parts, namely bed, column, sliding seat, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com