Novel sealing ring for rotary pump and manufacturing method of novel sealing ring

A manufacturing method and sealing ring technology, which are applied to pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of low pump volume efficiency, high manufacturing cost, inconvenient inspection and maintenance, etc., and achieve improved work efficiency, convenient processing, Easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

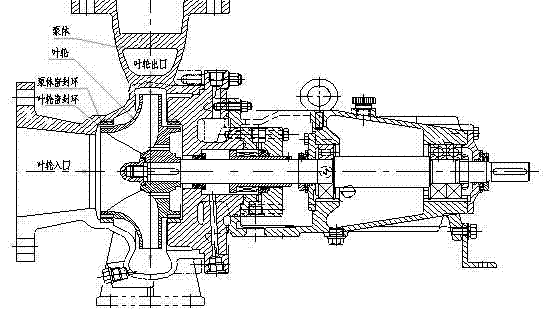

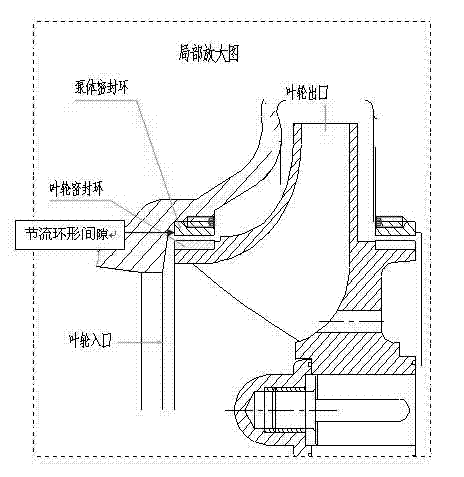

[0029] The sealing ring (1) is composed of a set of thin slices (2) whose axial thickness is much smaller than the radial width dimension.

[0030] The sealing ring (1) contains at least two and more thin slices (2).

[0031] The axial thickness of the sheet (2) is about 0.5 ~ 3mm.

[0032] The sheet (2) is composed of a fixed sheet (201) and a moving sheet (202);

[0033] The outer diameter of the stator (201) is closely connected to the installation part (301) of the pump body;

[0034] There is a gap between the inner hole of the stator (201) and the impeller seal ring (302), which is much larger than the normal seal ring gap;

[0035] The outer diameter of the moving piece (202) is 0.5 from the mounting position of the pump body (301). ~ 3mm radial clearance;

[0036] There is a smaller gap between the inner hole of the moving piece (202) and the impeller seal ring (302) than the normal seal ring gap;

[0037] The moving piece (202) can move radially between two adja...

Embodiment 2

[0046] The sealing ring in the conventional pump body is characterized as an integral type, and changed into a split combination type, more specifically, it is composed of a group of thin slices (0.5 ~ 3mm), the slices in this new type of seal ring are composed of a fixed piece that fits closely with the installation part of the pump body and a moving piece that has a certain radial gap with the installation part. Among them, the feature of the fixed plate is that there is a large gap between the inner hole and the impeller seal ring, which is far beyond the normal seal ring gap, and the outer diameter is precisely matched with the installation part of the pump body; the feature of the moving plate is that there is a ratio between the inner hole and the impeller seal ring. The clearance of the normal sealing ring is smaller, and the outer diameter of the stator (201) is closely connected to the installation part of the pump body (301) and there is a larger gap between the outer...

Embodiment 3

[0048] During assembly, rely on the fixed piece to initially press against the moving piece, but it can slide radially; when the pump is running, rely on the pressure difference between the inlet and outlet of the impeller to form a pressure difference between the two ends of the sealing ring, and further compress the sealing piece toward the impeller inlet. , Therefore, when the actual pump is running, the moving plate is stationary. Because the moving piece can slide in the radial direction, in the case of a large concentricity deviation between the housing part and the rotor part caused by various factors, the moving piece can still be moved by the rotor during assembly or in operation to move the moving piece slide radially to a new position, such as Figure 4As shown, a gap is formed with the impeller seal ring at the new position, so that the impeller seal ring and the pump body seal ring will not be stuck or seized. Because of its self-adaptive floating characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com