Underground coal mine reverse broaching and permeability increasing device and use method thereof

A reverse, coal mine technology, applied in the direction of drilling equipment and methods, safety devices, mining equipment, etc., can solve the problems of small drainage radius, polluted water source, poor permeability, etc., to improve gas drainage efficiency and reduce handling intensity , The effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

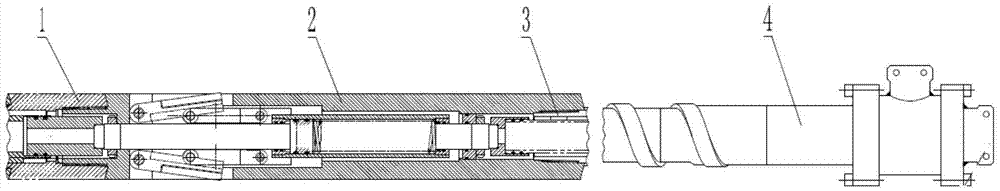

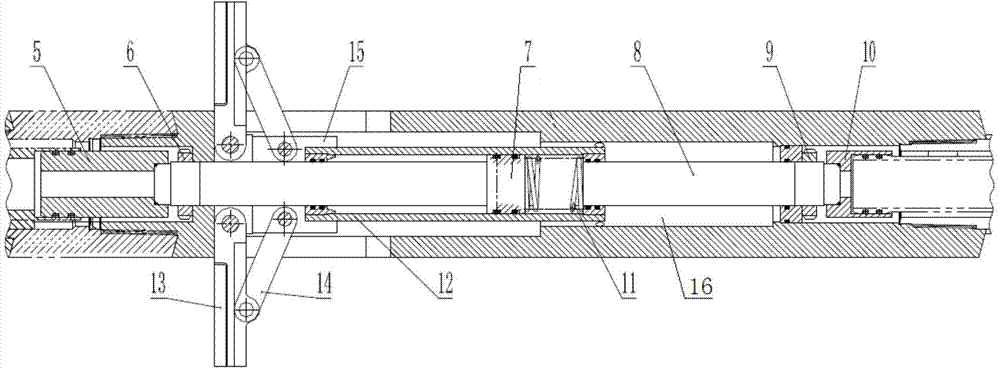

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the structure of the open state of the present invention, as shown in the figure: the reverse reaming and anti-reflection device for underground coal mines of the present embodiment includes a device housing 2, a central shaft 8 and a plane slider linkage; the central shaft 8 is set Inside the device housing 2, the planar slider linkage mechanism includes a swing bar 13 hinged to the device housing 2, a slider 15 slidingly connected to the central shaft 8 with a single degree of freedom, and a slider 15 connected to the slider 15 and the swing bar 13. Between the connecting rod 14, the swing rod 13 is provided with a cutting edge, and the plane slider connecting rod mechanism is provided with at least two circumferentially around the central axis 8, and the sliding block 15 can be driven by the corresponding connecting rod 14 along the central axis 8. Correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com