Novel template structure with steel template attached to Teflon and manufacturing method of novel template structure

A technology of polytetrafluoroethylene and tetrafluoroethylene, which is applied in the field of new formwork structure and its manufacturing, to achieve the effect of excellent temperature resistance, high price and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

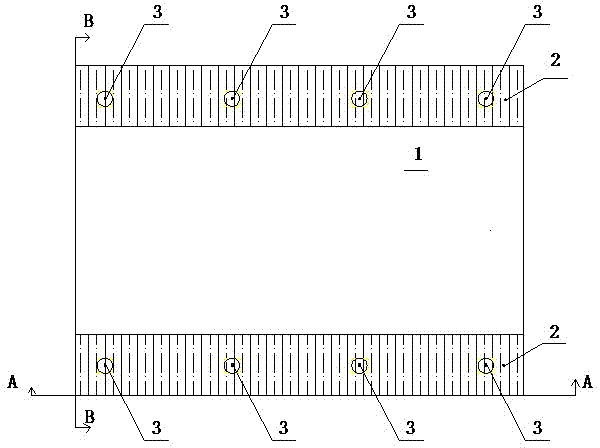

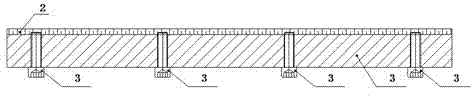

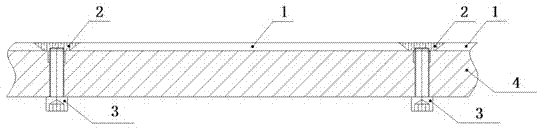

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as Figure 1~4 As shown, a new formwork structure in which a steel formwork is pasted with polytetrafluoroethylene includes a steel formwork 4, and a tetrafluoroethylene plate 1 is pasted on the top of the steel formwork 4. The tetrafluoroethylene boards 1 are provided with multiple pieces, the two sides of the adjacent tetrafluoroethylene boards 1 are wedge-shaped, and there are buckled blocks 2 between the adjacent tetrafluoroethylene boards. The side is provided with a wedge-shaped inclined surface matching with both sides of the tetrafluoroethylene plate, and the lower part of the clamping block is extended with a convex part embedded in the steel formwork, and the clamping block is fixedly connected with the steel formwork.

[0021] The bottom of the steel formwork is provided with fixing bolts 3 that pass through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com