Wool yarn looping device of warp knitting machine with double needle beds

A double-needle bed warp knitting machine and knitting device technology, which is applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problem of increasing the load of the swinging main shaft of the bar, reducing the reliability of the knitting work, and the lateral movement of the bar Inaccurate and other problems, to achieve the effect of improving fabric quality, reducing load, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

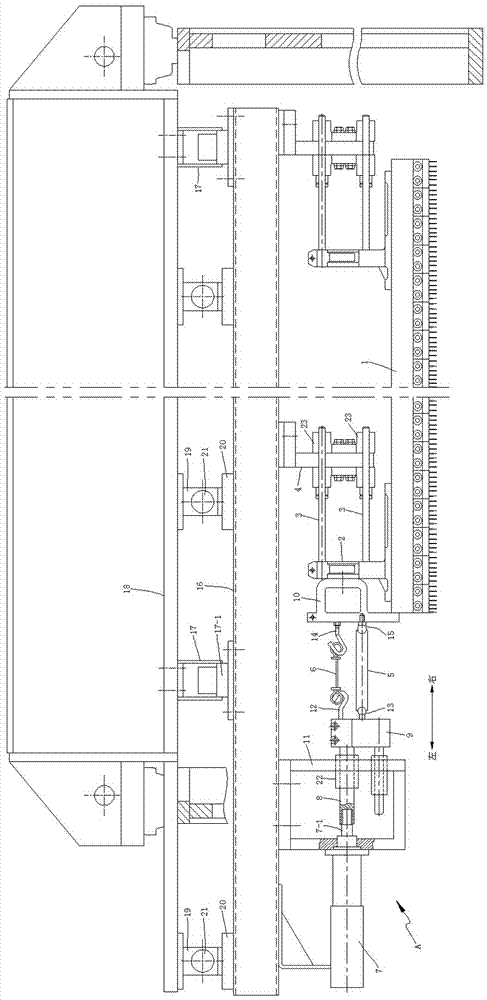

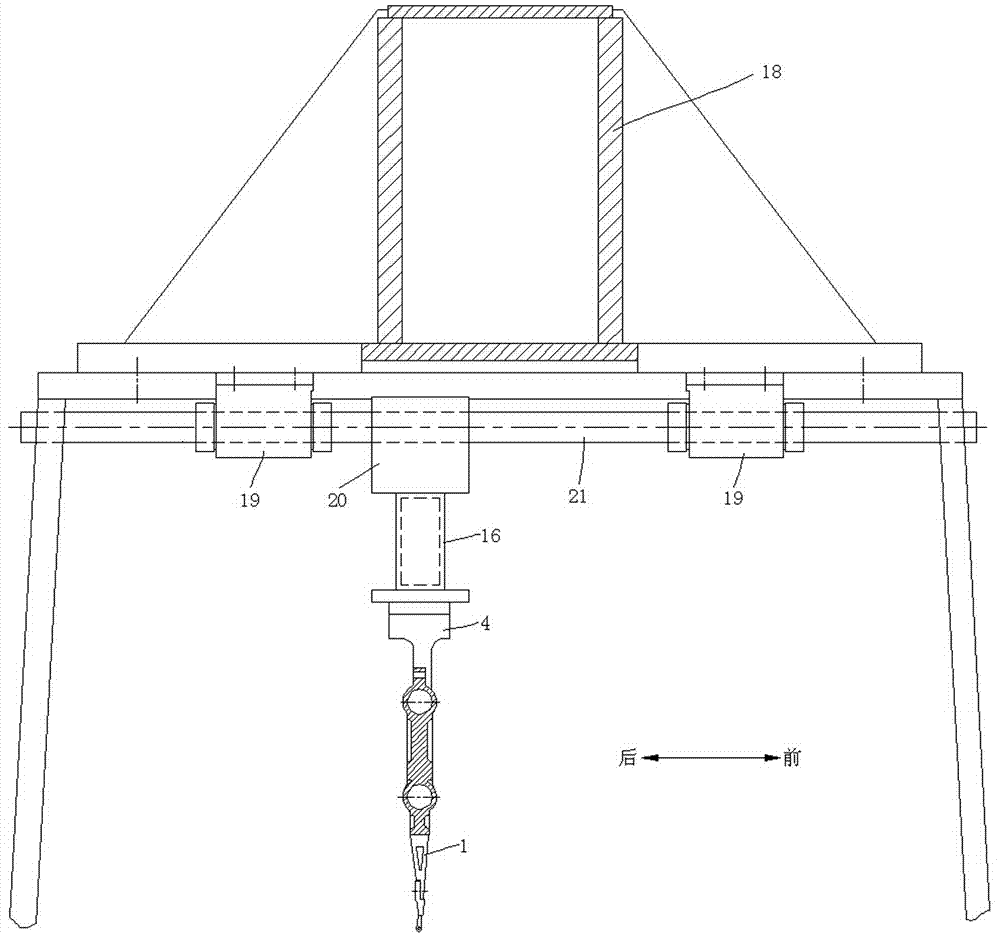

[0018] As a preferred embodiment of the present invention, the longitudinal movement driving device 17 is a linear motor, and the linear motor has a stator and a mover 17-1 that performs reciprocating linear motion relative to the stator, and the support tube 16 passes through The bolt is fixedly connected with the mover 17-1 of the linear motor, and the linear motor is fixedly installed on the frame beam 18 of the warp knitting machine through bolts. In the present invention, there may be multiple linear motors, preferably two in the present invention, and the longitudinal movement drive device 17 may also be an electric cylinder or other linear drive devices.

[0019] As another preferred embodiment of the present invention, such as figure 1 , 2 As shown, a linear bearing seat 19 is fixed on the frame beam 18 of the warp knitting machine, a linear bearing is installed in the linear bearing seat 19, a mounting seat 20 is fixed on the support tube 16, and a mounting seat 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com