Method for preparing high-purity calcium sulfate dihydrate crystal whisker by using metallurgic flue gas desulfurization gypsum recrystallization process

A technology of calcium sulfate dihydrate and desulfurized gypsum, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, to achieve the effects of high efficiency, low energy consumption, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

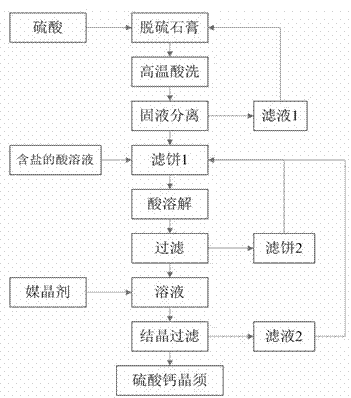

[0043] Such as figure 1 As shown, the metallurgical flue gas desulfurization gypsum is crushed to a particle size of less than 80 mesh, weighed 100.00g, and then added to a 1000mL beaker at the same time as the pre-prepared 1.0mol / L sulfuric acid solution, and stirred for 30min to make a small amount of calcium carbonate and calcium oxide, etc. Convert to calcium sulfate, after the reaction is complete (there is no air bubbles in the slurry, then stir and react for 10 minutes), raise the temperature to 60°C, stir at a speed of 150r / min, and react for 2 hours, after the reaction is complete (desulfurized gypsum recrystallization and stratification ), let it stand for stratification, pour out the supernatant (filtrate 1) (recycled), and the lower layer of gypsum (filter cake 1) is washed with water, suction filtered, and dried for later use.

[0044] Weigh 50.00g of the above-mentioned acid-washed and dried desulfurized gypsum, add it together with 500mL, 2mol / L hydrochloric ac...

Embodiment 2

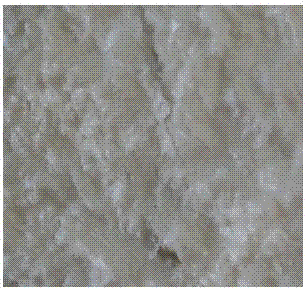

[0046] Recover 500ml of the filtrate 2 in Example 1, and add 50.0g of desulfurized gypsum after pickling into a 1000mL beaker at the same time, immerse more than two-thirds of the volume in a 90°C constant temperature water bath, keep the temperature and stir for 4h, after the reaction is completed, while the Hot suction filtration, the filter cake can be recycled, the filtrate is transferred to a 1000mL beaker, and 0.5wt% MgCl is added as a crystallization agent 2 In the filtrate, place it in a constant temperature water bath at 50°C for cooling and crystallization for 12 hours. After the crystallization is completed, filter with suction and wash with water. The filtrate can be recycled, and then the filter cake is dried in an oven at 80°C for 12 hours to obtain 16.2g of high-purity calcium sulfate dihydrate whisker product. Its appearance is shown in Figure 3, and the SEM picture is as follows Figure 4 shown. Calcium sulfate dihydrate content ≥ 99.00% (wt%), whiteness grea...

Embodiment 3

[0048] Take by weighing 50.00 g of desulfurized gypsum after pickling and drying in Example 1, and mix it with 500 mL, 2mol / L of mixed salt (Al 2 (SO 4 ) 3 1.0wt% and CaCl 2 4.0wt%) hydrochloric acid solution into a 1000mL flask, immerse more than two-thirds of the volume in a 90°C constant temperature water bath, keep the temperature and stir for 1h, after the reaction is completed, suction filter while it is hot, the filter cake can be recycled, Transfer to a 1000mL beaker, add a mixed crystallization agent (containing 0.5wt%MgCl 2 , 0.5wt% sodium oleate) in the filtrate, placed in a constant temperature water bath at 20°C for cooling and crystallization for 12 hours. Suction filtration after the crystallization is completed, the filtrate 2 can be recycled, and then the filter cake is dried in an oven at 80°C for 12 hours to obtain 22.6 g of high-purity calcium sulfate dihydrate whisker product. Calcium sulfate dihydrate content ≥ 99.00% (wt%), whiteness greater than 98%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com