Electrolysis device based on electrowetting-on-dielectric layer principle, and manufacturing method thereof

A dielectric layer and electrowetting technology, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of strict process conditions, low integration, single function, etc., achieve the effect of simplifying the chip structure, expanding the application range, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

[0031] The electrolytic device based on the principle of electrowetting on the dielectric layer provided by the present invention is realized through electrode design and driving signal control, so it can be configured in various ways and can be configured in various digital microfluidic chips.

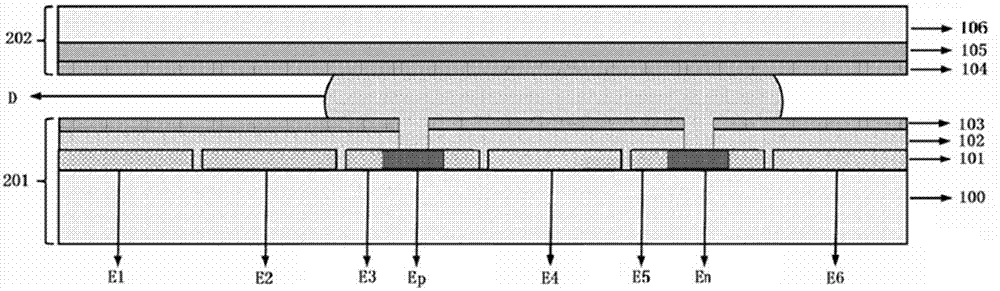

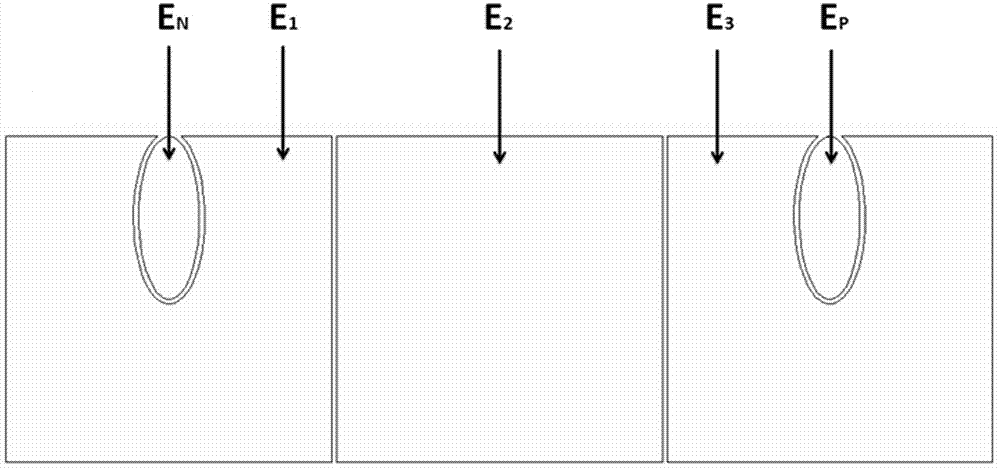

[0032] Schematic diagram (longitudinal sectional view) of the principle structure of the present invention such as figure 1 shown. On the insulating first substrate 100 are the driving electrodes E1-E6 and the electrolysis electrodes Ep and En of the present invention, wherein the electrolysis electrodes Ep and En are respectively embedded in the driving electrodes E3 and E5, but are electrically isolated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com